Mixed flow type water turbin having H-type flow path rotary wheel

A water turbine and mixed-flow technology, applied in the field of fluid machinery and engineering equipment, can solve the problems of unit safety operation hazards, water turbine efficiency reduction, water turbine operation restrictions, etc., to expand high-efficiency operation area, improve flow conditions, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings.

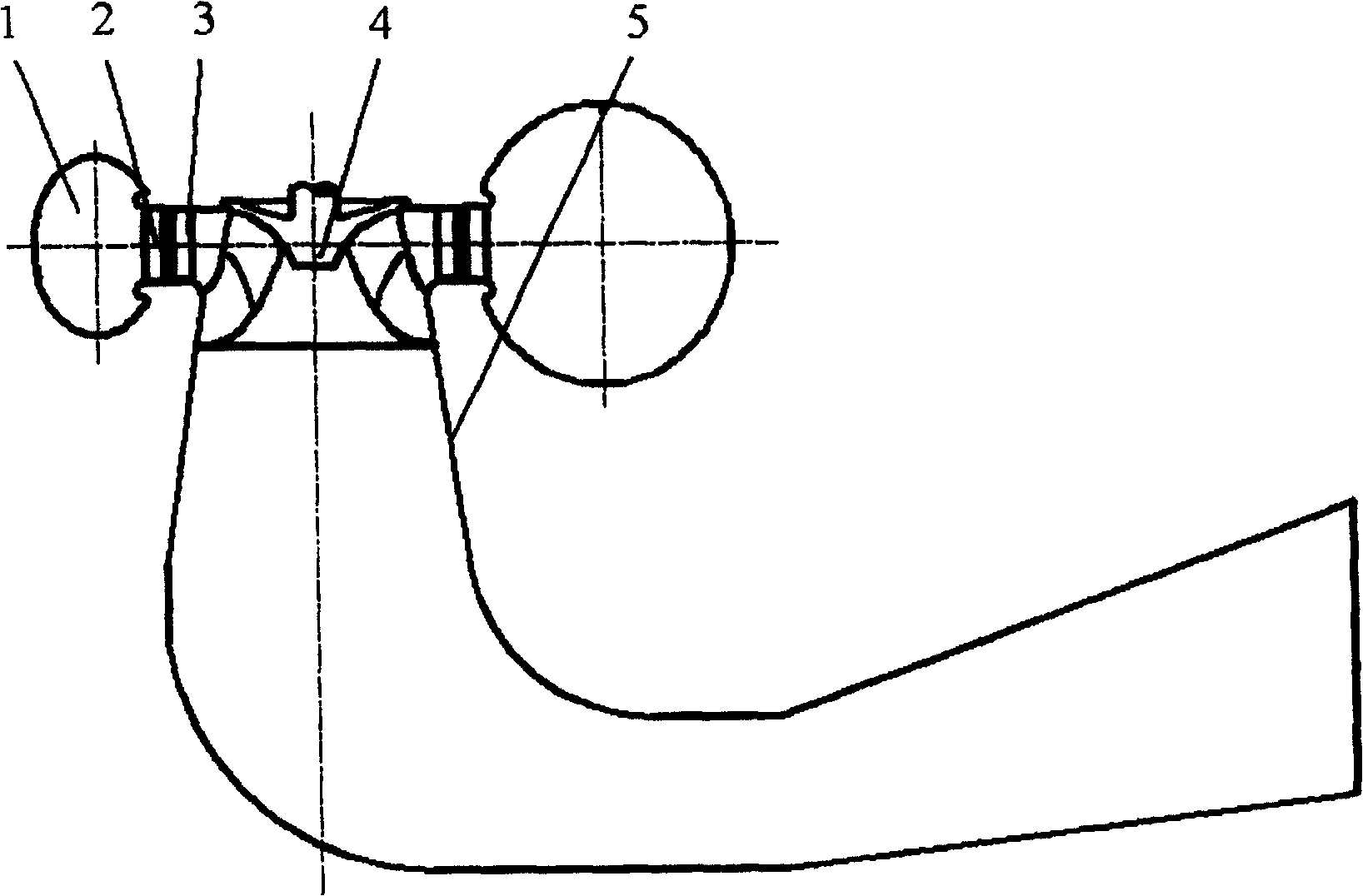

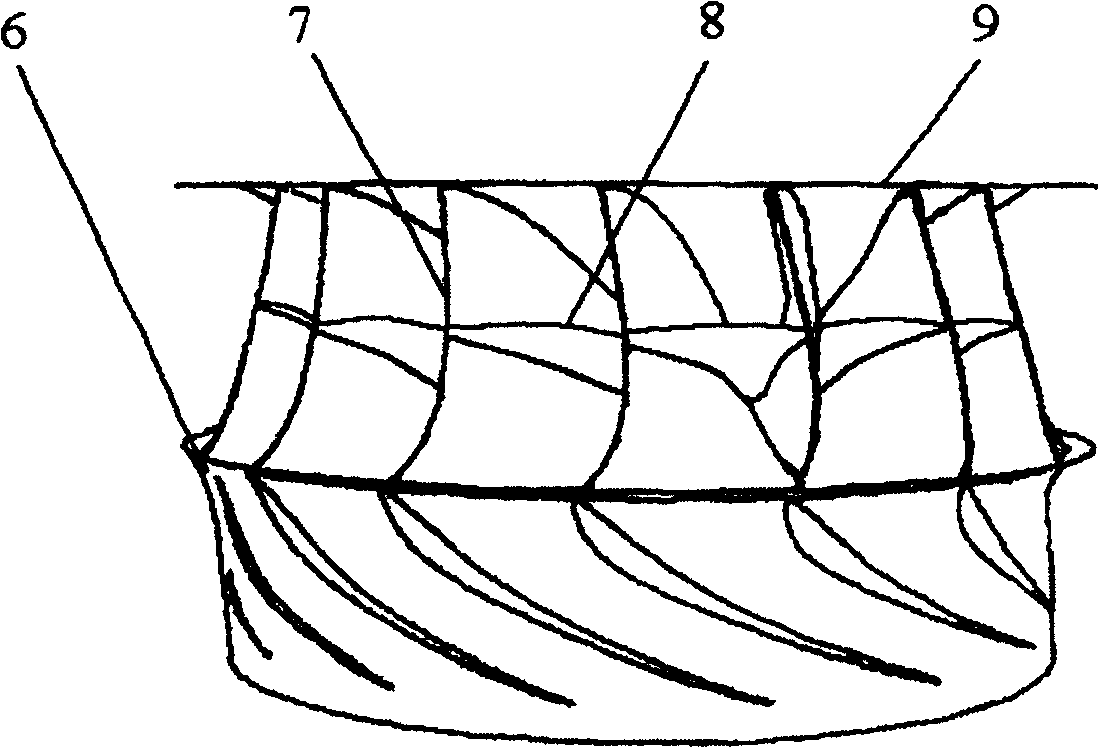

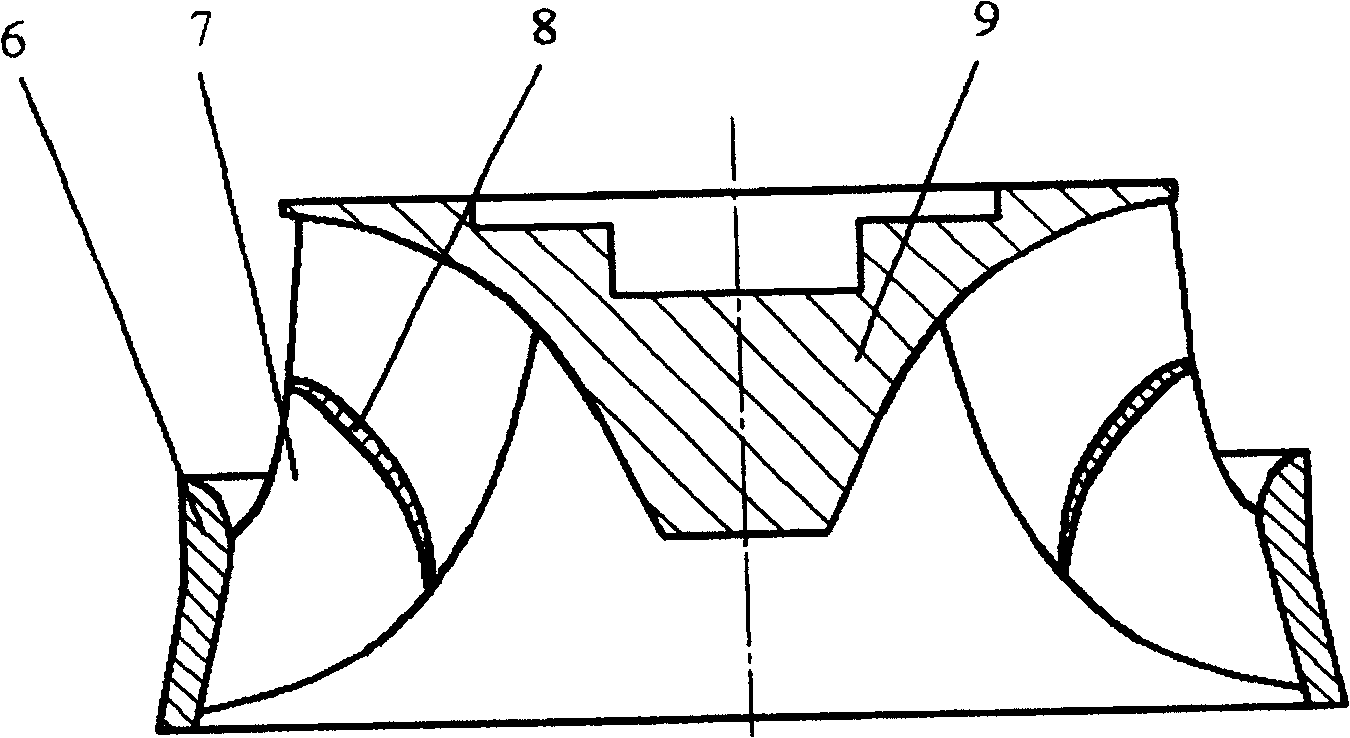

[0015] figure 1 It is a schematic structural diagram of the Francis turbine of the H-type channel runner provided by the present invention. The Francis turbine includes a volute 1, a fixed guide vane 2, a movable guide vane 3, an H-shaped runner 4 and a draft tube 5 according to the direction of water flow; the H-shaped runner 4 consists of an upper crown 9, a lower ring 6. The rotor blades 7 fixed between the upper crown and the lower ring and the guide vanes 8 are formed, and the guide vanes 8 are installed between every two adjacent runner blades 7 (such as figure 2 , image 3 As shown), an H-shaped flow channel is formed; the guide vane 8 is placed in the middle of the flow channel, and the length is the same as that of the runner blade. The streamline in the middle of the flow channel under the optimal working condition is the bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com