Heat source-side unit and refrigeration cycle device

A heat source side, refrigerant technology, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of inability to measure the temperature of the two-phase refrigerant, not considering the state of the refrigerant, etc., to optimize control and improve reliability. The effect of stability and efficient system protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

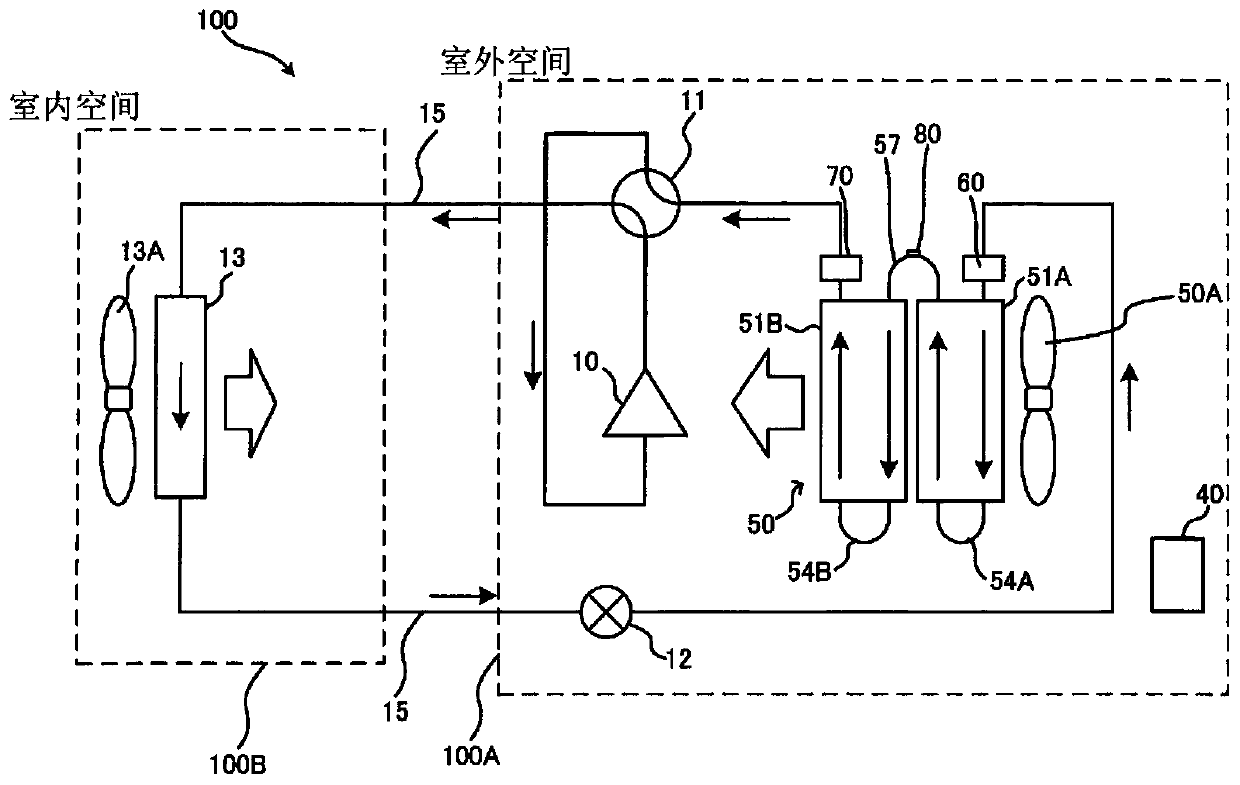

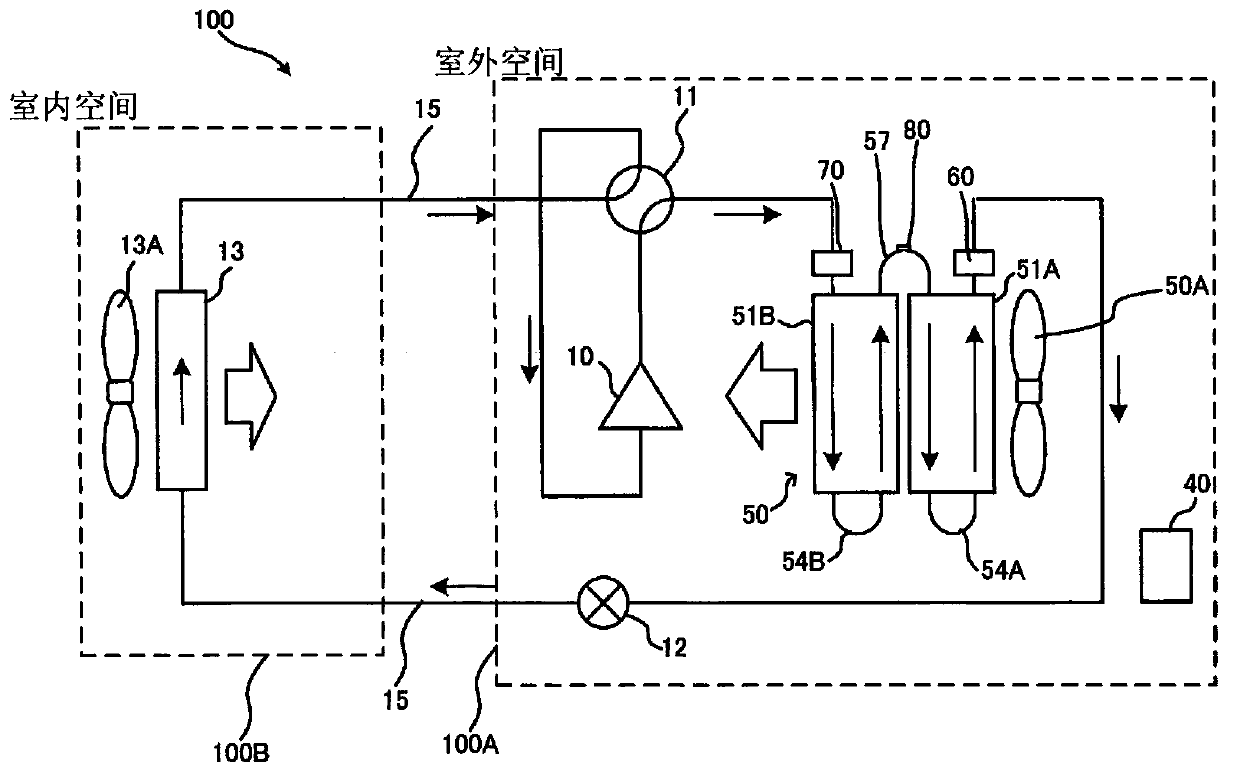

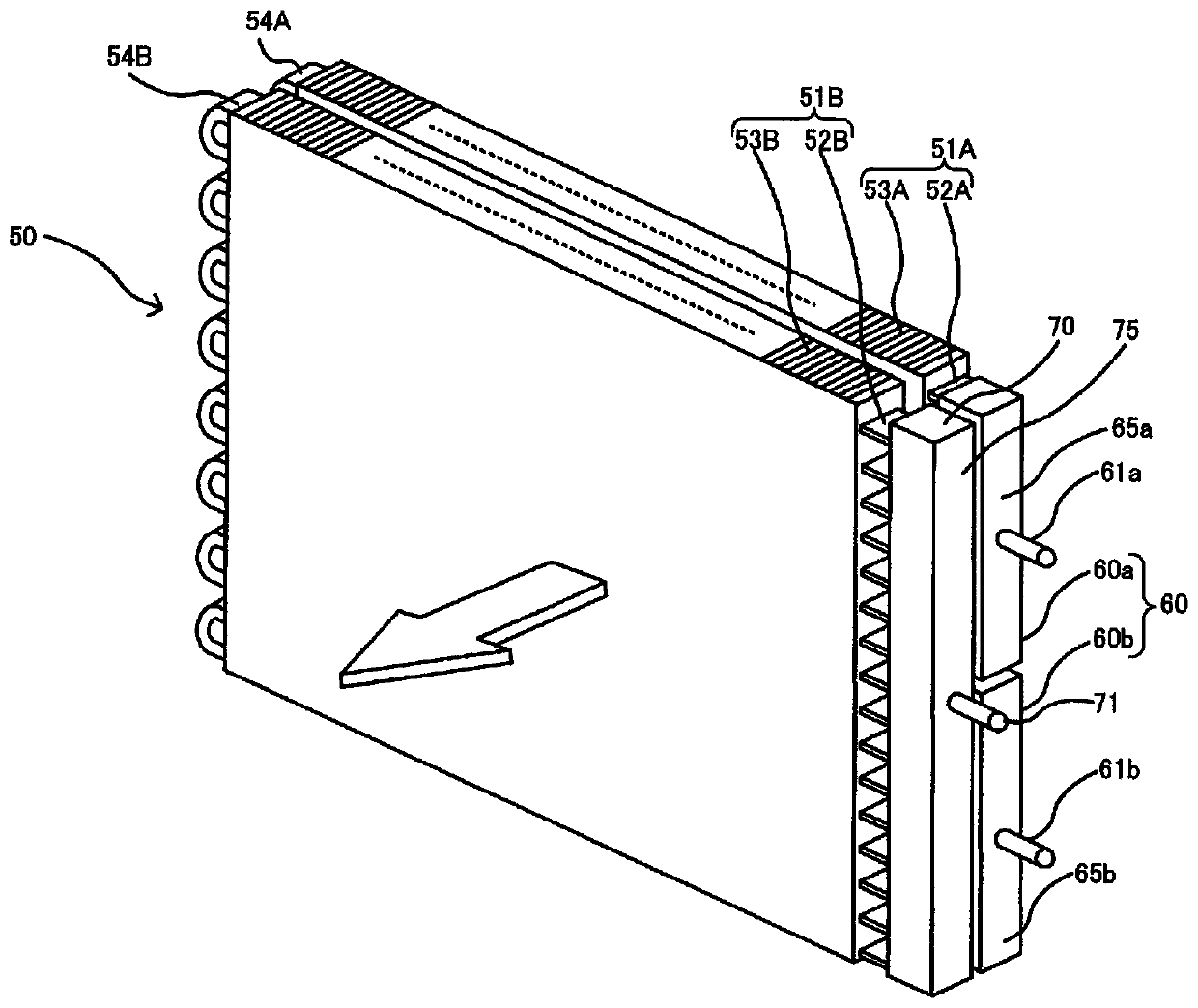

[0028] Hereinafter, the heat source side unit and the refrigeration cycle apparatus of this invention are demonstrated using drawing.

[0029] In addition, the configuration, operation, etc. described below are merely examples, and the heat source side unit and refrigeration cycle apparatus of the present invention are not limited to such configurations, operations, and the like. In addition, in each figure, the same reference numerals are assigned to the same or similar components, or the reference numerals are omitted. In addition, illustrations are appropriately simplified or omitted for minute structures. In addition, repeated or similar descriptions are appropriately simplified or omitted.

[0030] In addition, the case where the heat source side unit of the present invention is applied to an air conditioner as an example of a refrigeration cycle device will be described below, but it is not limited to such a case, and it can also be applied to other refrigeration cycles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com