Multi-tray insect breeding device and system

A breeding system and insect technology, applied in animal husbandry and other fields, can solve problems such as the difficulty of manual insect feeding, achieve the effects of reducing complexity and labor intensity, improving visibility, and prolonging the time for foraging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

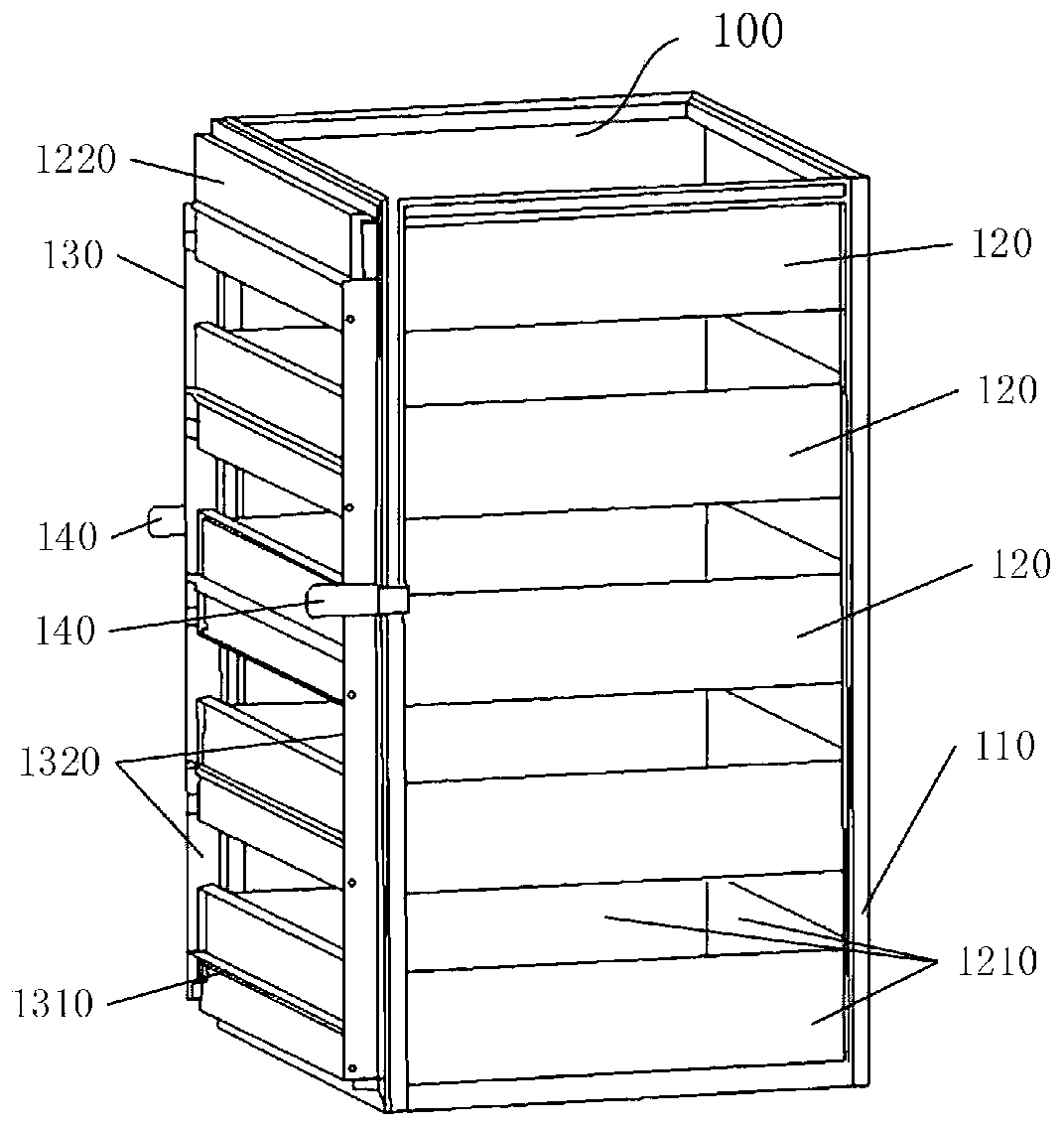

[0032] Please refer to figure 1 , figure 1 It is a structural diagram of the multi-tray worm breeding device 100 provided by the present invention. like figure 1 As shown, the device includes a metal frame 110 and at least two culture boxes 120 .

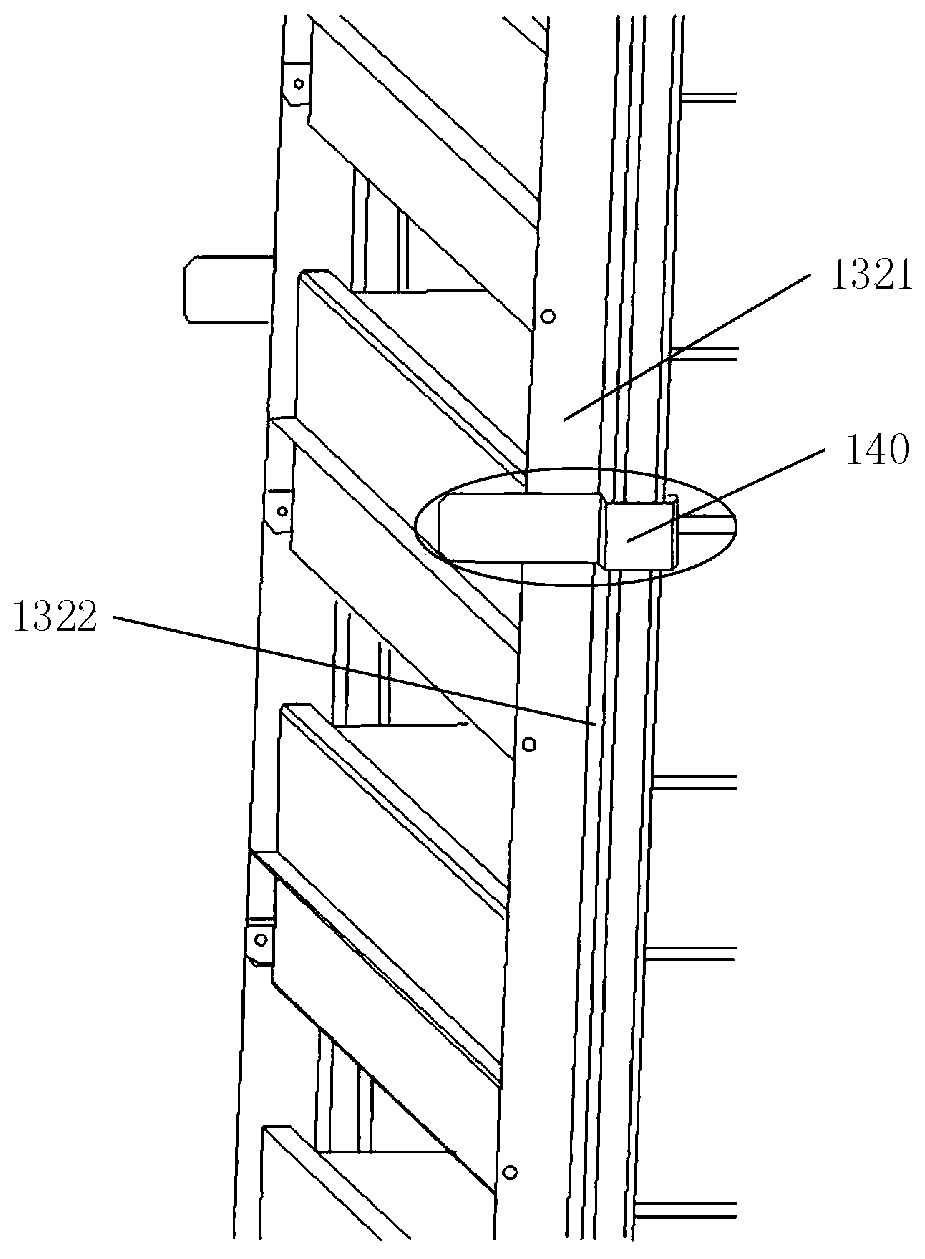

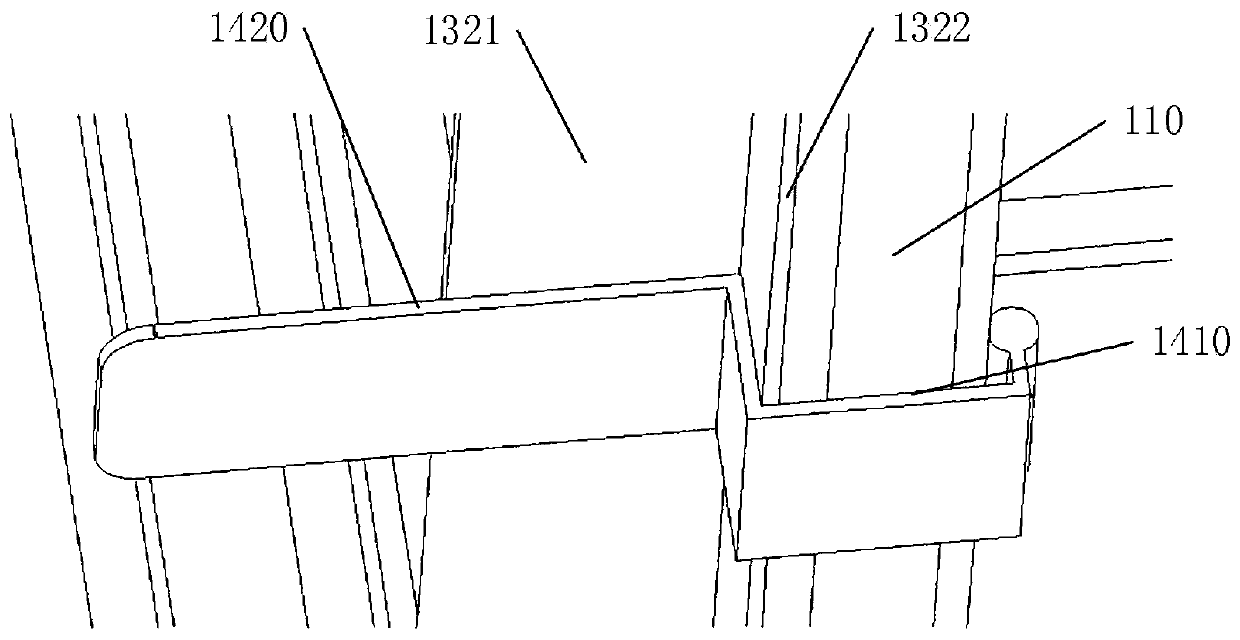

[0033] The same side of the body of all breeding boxes 120 has a first opening, the edge of the first opening is hingedly provided with a cover, and a locking portion is provided between the cover and the body for firmly fastening the cover on the body. As an example, figure 1 In the cultivation device shown, the entire left sides of the five cultivation boxes 120 form a first opening, and the upper edge of the first opening is hingedly provided with a cover 1220 .

[0034] As a preferred embodiment, the three sides of the body of the breeding box 120 are transparent acrylic plates, and the bottom of the body is a PP plate. The cover body 1220 is a transparent acrylic plate. The upper side of the breeding box is hollowed out t...

Embodiment 2

[0049] The invention also provides a multi-tray worm breeding system. like Figure 6 and 7 As shown, the system includes the above-mentioned multi-tray worm breeding device 100 , unloading platform 200 and breeding area 300 . Wherein the unloading platform 200 comprises the third inclined plane 230, the plane 240, the first inclined plane 210, and the second inclined plane 220 connected in sequence, the inclination rate of the first inclined plane 210 is less than the inclination rate of the second inclined plane 220, the first inclined plane 210 and the second inclined plane A baffle 250 is provided at the junction of the slope 220 , and the bottom end of the third slope 230 is connected to the ground of the breeding area 300 .

[0050] In the non-discharging stage, the cultivation device is placed on the flat ground of the cultivation area 300 . When unloading is required, the cultivation device is moved to the unloading platform 200, and then the first slope 210 is reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com