Double-sided cleaning equipment for veterinary equipment

A technology for cleaning equipment and equipment, applied in the field of double-sided cleaning equipment for veterinary equipment, and can solve problems such as affecting treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

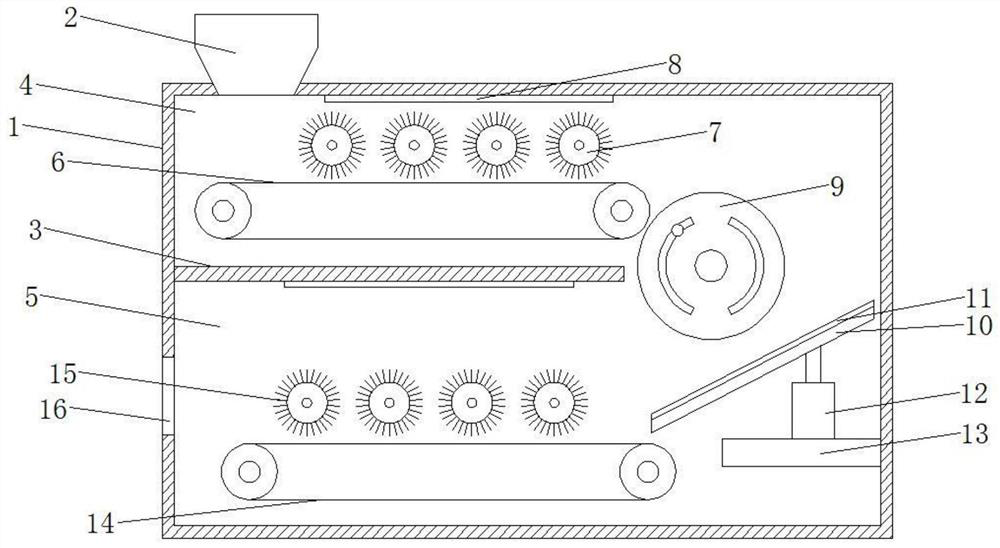

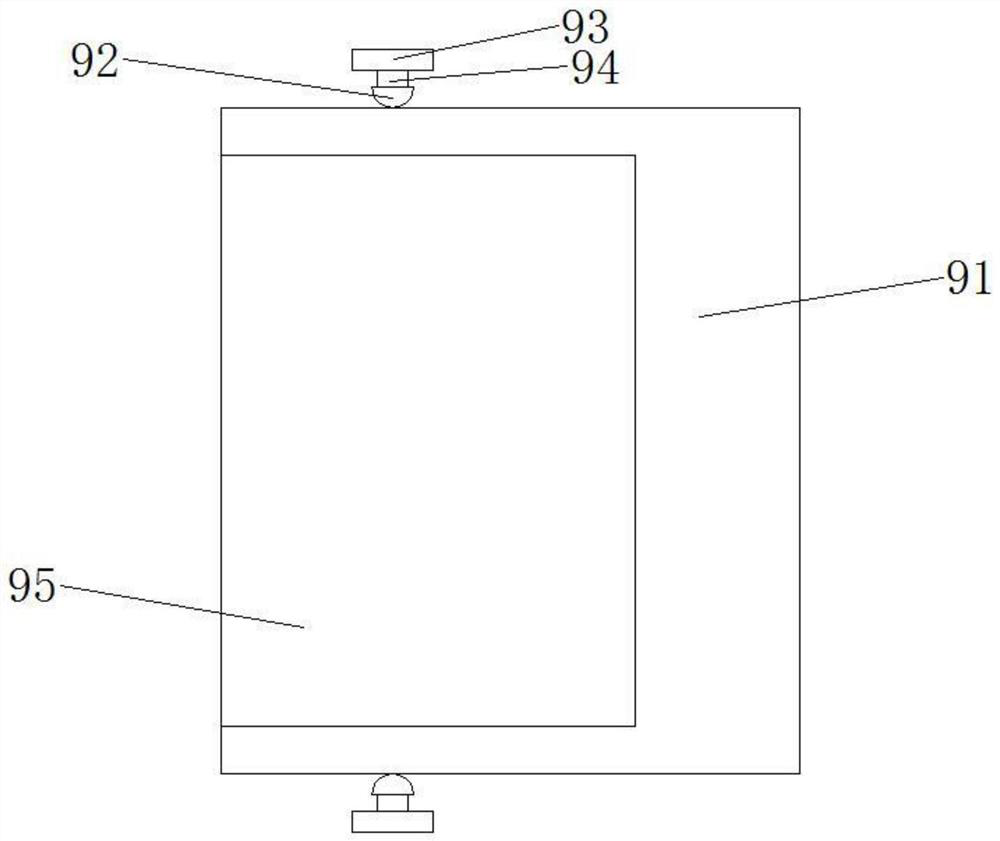

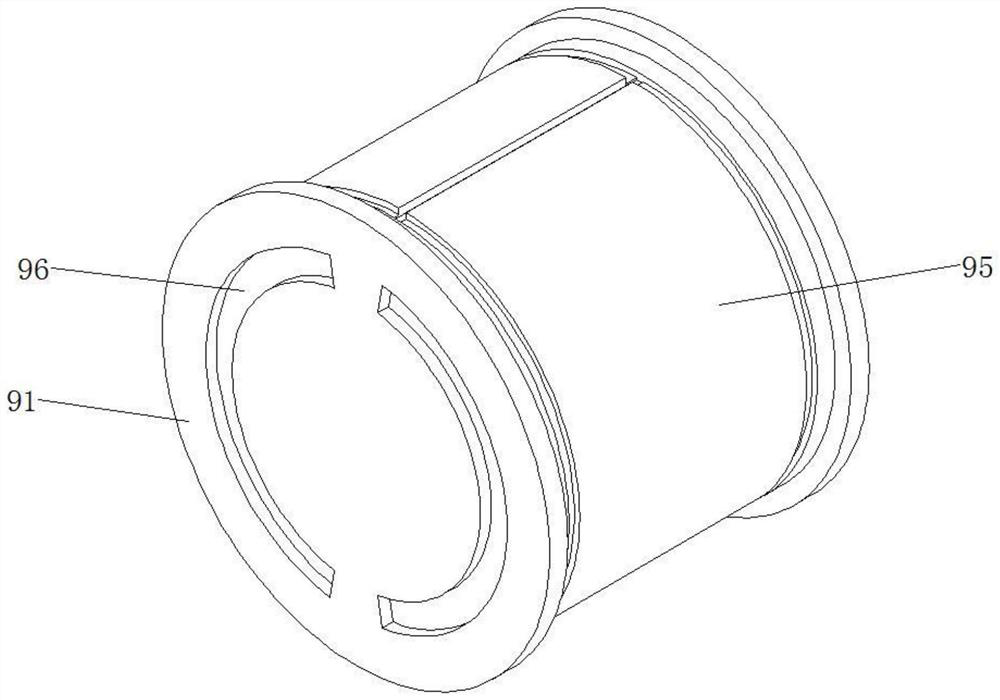

[0019] Please refer to the figure, in the embodiment of the present invention, a double-sided cleaning equipment for veterinary equipment includes a box body 1, a filling port 2, a partition 3 and an outlet 16; the filling port 2 is arranged at the top left end of the box body 1, The veterinary equipment is loaded into the box body 1 from the filling port 2; a horizontal partition 3 is fixedly installed on the inner wall on the left side of the box body 1, and the partition plate 3 is located in the middle, and the box body 1 is divided into upper and lower parts. Two chambers are respectively the first cleaning chamber 4 and the second cleaning chamber 5. The right end of the partition plate 3 is not connected to the other side wall of the box body 1, so that the right side of the partition plate 3 is a communication port, and the first cleaning chamber The cavity 4 and the second cleaning cavity 5 are in communication.

[0020] The first cleaning chamber 4 is provided with a...

Embodiment 2

[0024] On the basis of Embodiment 1, a layer of sponge layer 11 is laid on the upper surface of the slant plate 10, so that the instrument can scrub its lower surface during the process of sliding down, and the lower side of the slant plate 10 is fixedly connected with a The height adjustment device 12 on the top, the height adjustment device 12 is a hydraulic cylinder structure, the height adjustment device 12 is fixed by the support seat 13, the height of the swash plate 10 is adjusted through the height adjustment device 12, and it is adjusted for different volumes of equipment, so that the lower end It is smoother on the second conveyor belt 14 .

[0025]Put the veterinary equipment into the box body 1 from the loading port 2, drop it on the first conveyor belt 6 in the first cleaning chamber 4, transport it to the right through the first conveyor belt 6, and brush it through the first cleaning roller 7 , the right end of the first conveying belt 6 of the instrument falls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com