Fuzzy servo control system and method for material identification of insulating ceramic coating-metal EDM

A technology of insulating ceramics and servo control, applied in metal processing equipment, electric processing equipment, circuits, etc., can solve the problems of effective adjustment of insulating ceramic-metal material discharge gap, poor aperture consistency, and low processing efficiency, so as to improve processing efficiency and processing quality, improving the gap discharge state, and ensuring the effect of processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

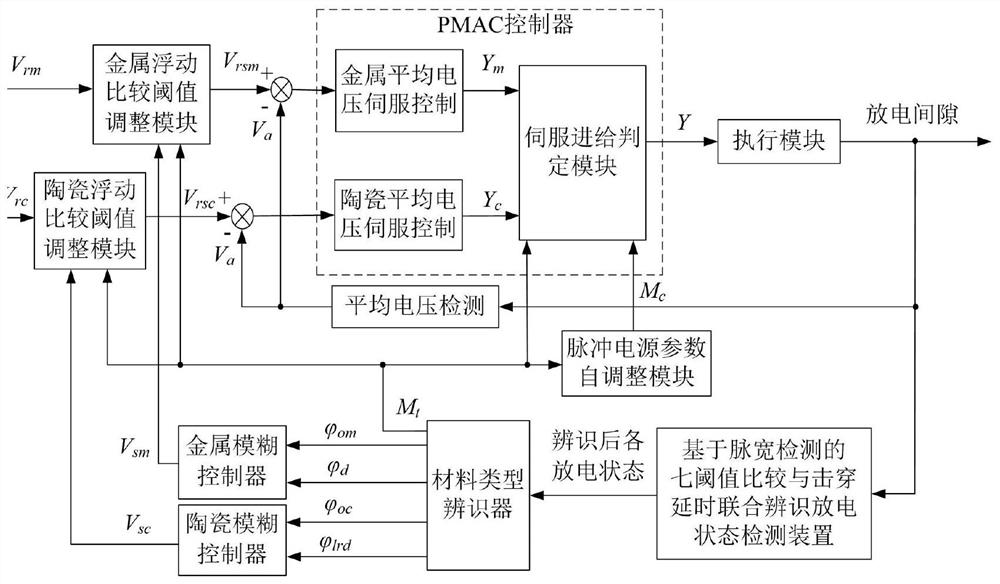

[0033] Specific implementation mode 1: This implementation mode provides a fuzzy servo control system for the identification of insulating ceramic coating-metal EDM materials, such as figure 1 As shown, the system includes an average voltage detection module, a pulse power supply parameter self-adjustment module, a PMAC controller, a metal floating comparison threshold adjustment module, a ceramic floating comparison threshold adjustment module, a metal fuzzy controller, a ceramic fuzzy controller, and material type identification Device, seven-threshold comparison based on pulse width detection and breakdown delay joint identification discharge state detection device and execution module, wherein:

[0034] The average voltage detection module is used to realize the real-time detection of the average voltage of the discharge gap;

[0035] The pulse power supply parameter self-adjustment module is used to identify the sign M according to the material type c Realize the convers...

specific Embodiment approach 2

[0059] Specific implementation mode 2: This implementation mode provides a fuzzy servo control method for identifying insulating ceramic coating-metal EDM materials, and the method includes the following steps:

[0060] Step 1. The discharge state detection method based on the seven-threshold comparison of pulse width detection and the joint identification of breakdown delay is used to identify the gap discharge state during the processing of insulating ceramic-metal materials.

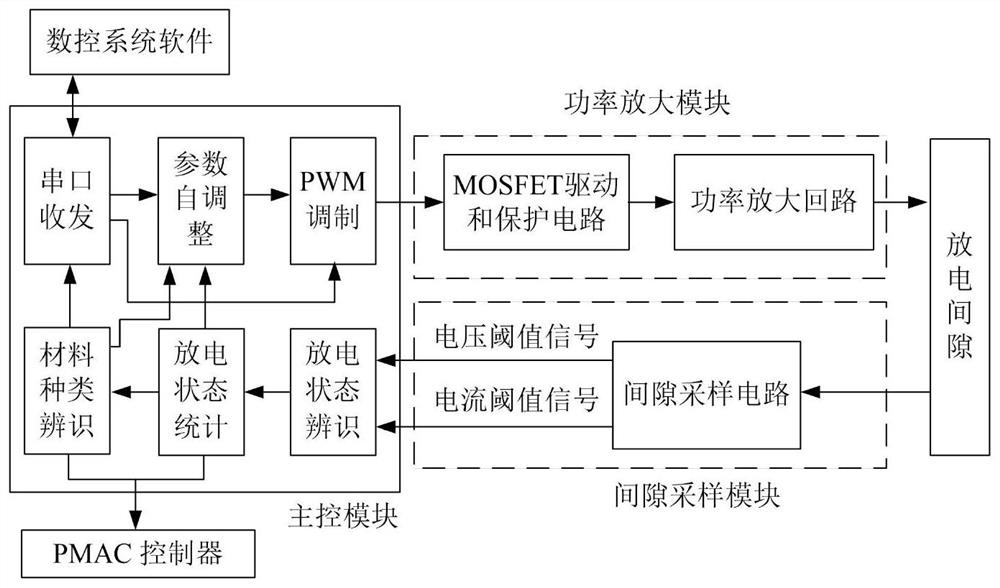

[0061] In this step, the voltage and current change information of the discharge gap is collected through the gap voltage sampling circuit and the gap current sampling circuit, and through the main control module of the pulse power supply based on CPLD or FPGA, it is judged whether there is a breakdown delay in the current discharge state, based on the discharge gap Medium voltage and current change information, through the joint logic operation of breakdown delay and threshold value comparison, identi...

specific Embodiment approach 3

[0111] Specific implementation mode three: as Figure 5 As shown, the specific implementation steps of the fuzzy servo control program based on the material type provided by this embodiment are as follows:

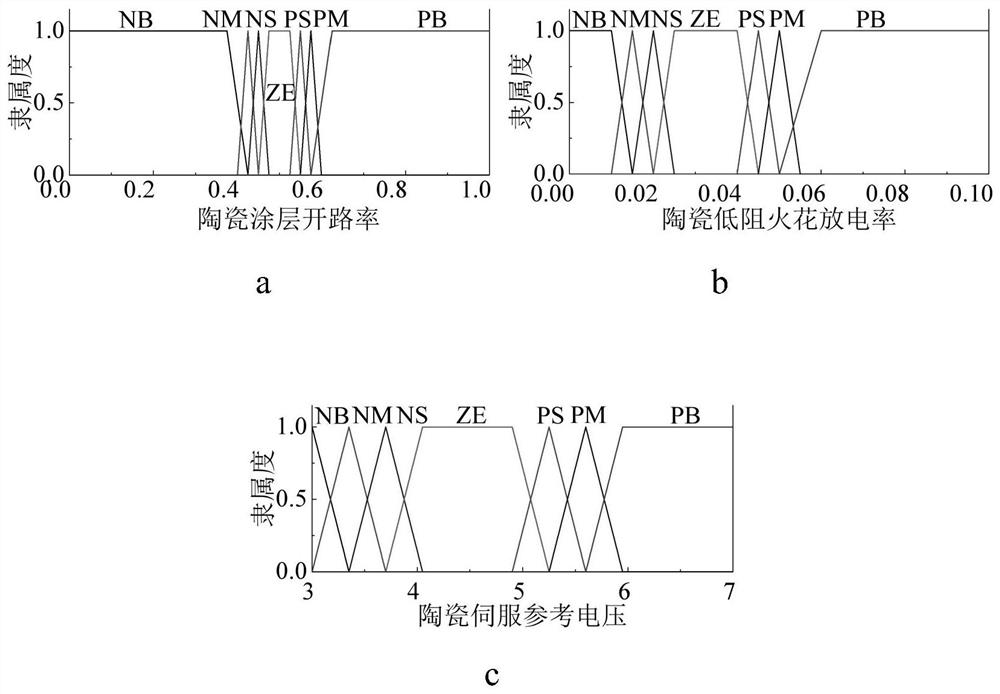

[0112] During processing, the control system initializes variables such as the servo reference voltage and the initial material type flag to ensure the stable operation of the system. After the main variables are initialized, the current gap discharge state is detected, and the time of each discharge state is counted. When the statistical period is reached, the relative rate of spark discharge between ceramics and metals within the statistical period is calculated, the current material type is distinguished according to the material judgment basis, and the optimal processing parameters are self-adjusted. The ceramic fuzzy controller and the metal fuzzy controller are respectively based on the ceramic open-circuit rate in the statistical period and low resistance spark dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com