Broken cutter detection device

A detection device and tool breaking technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problem of not being able to automatically detect tool breakage, and achieve the effect of avoiding processing loss and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

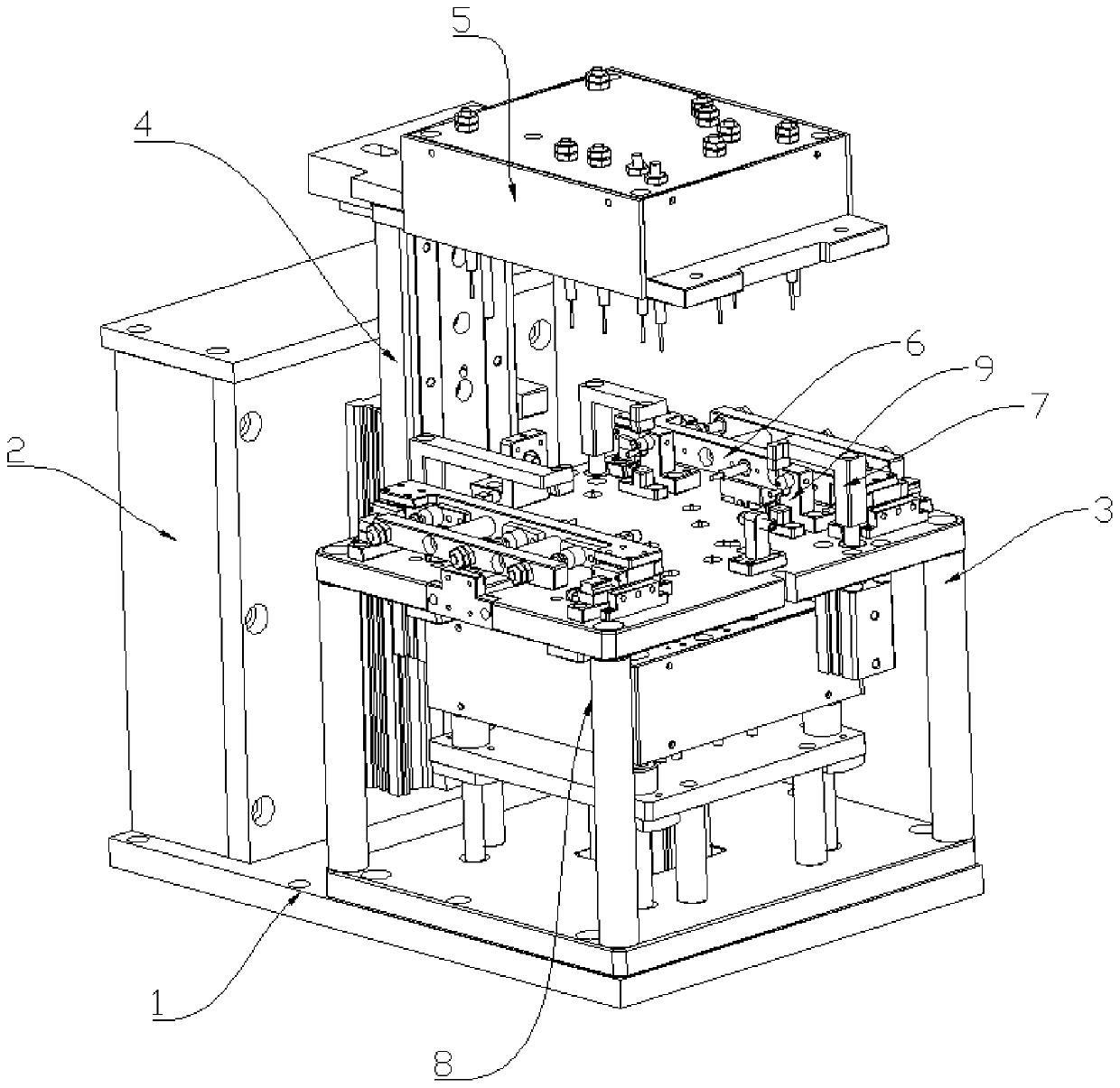

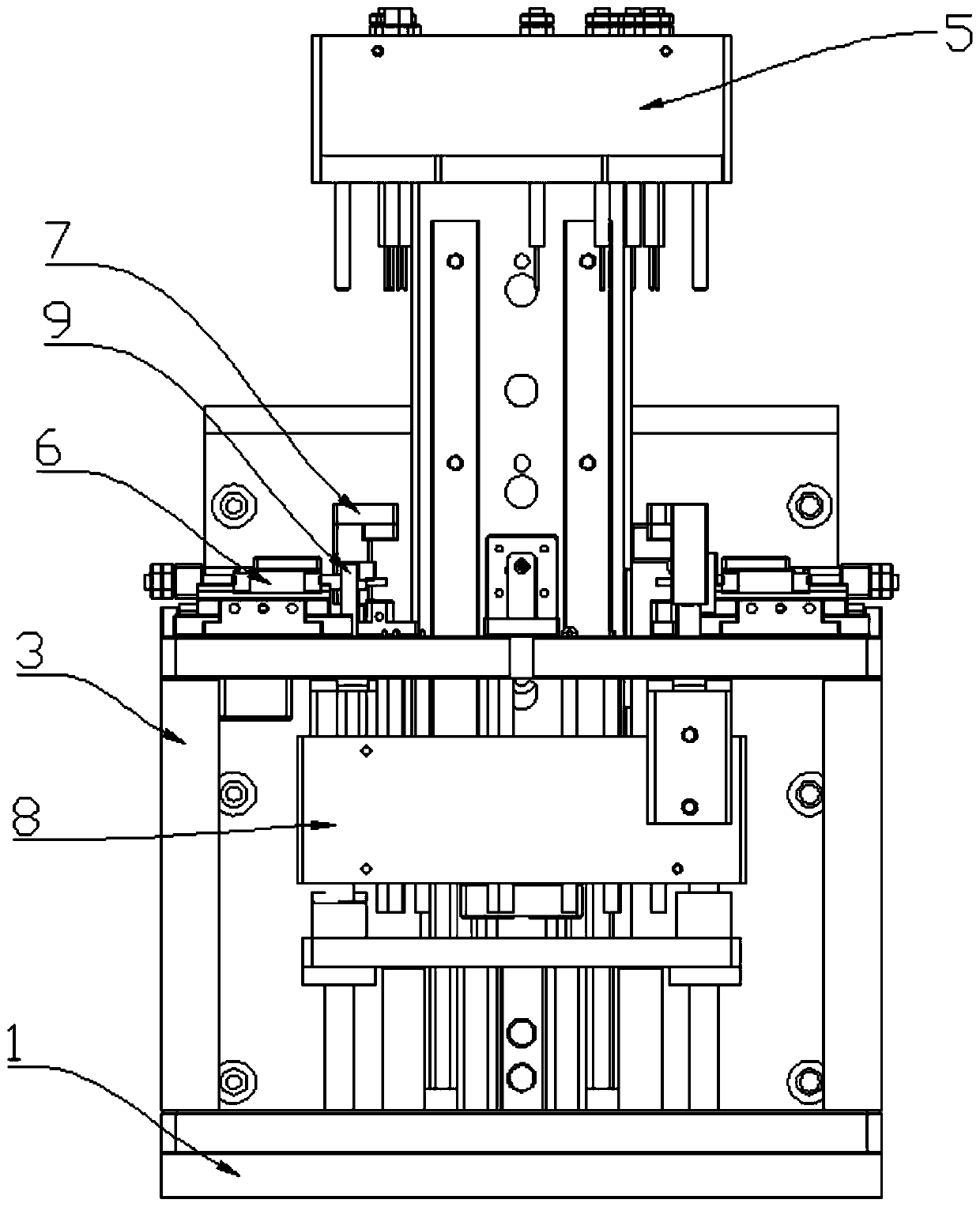

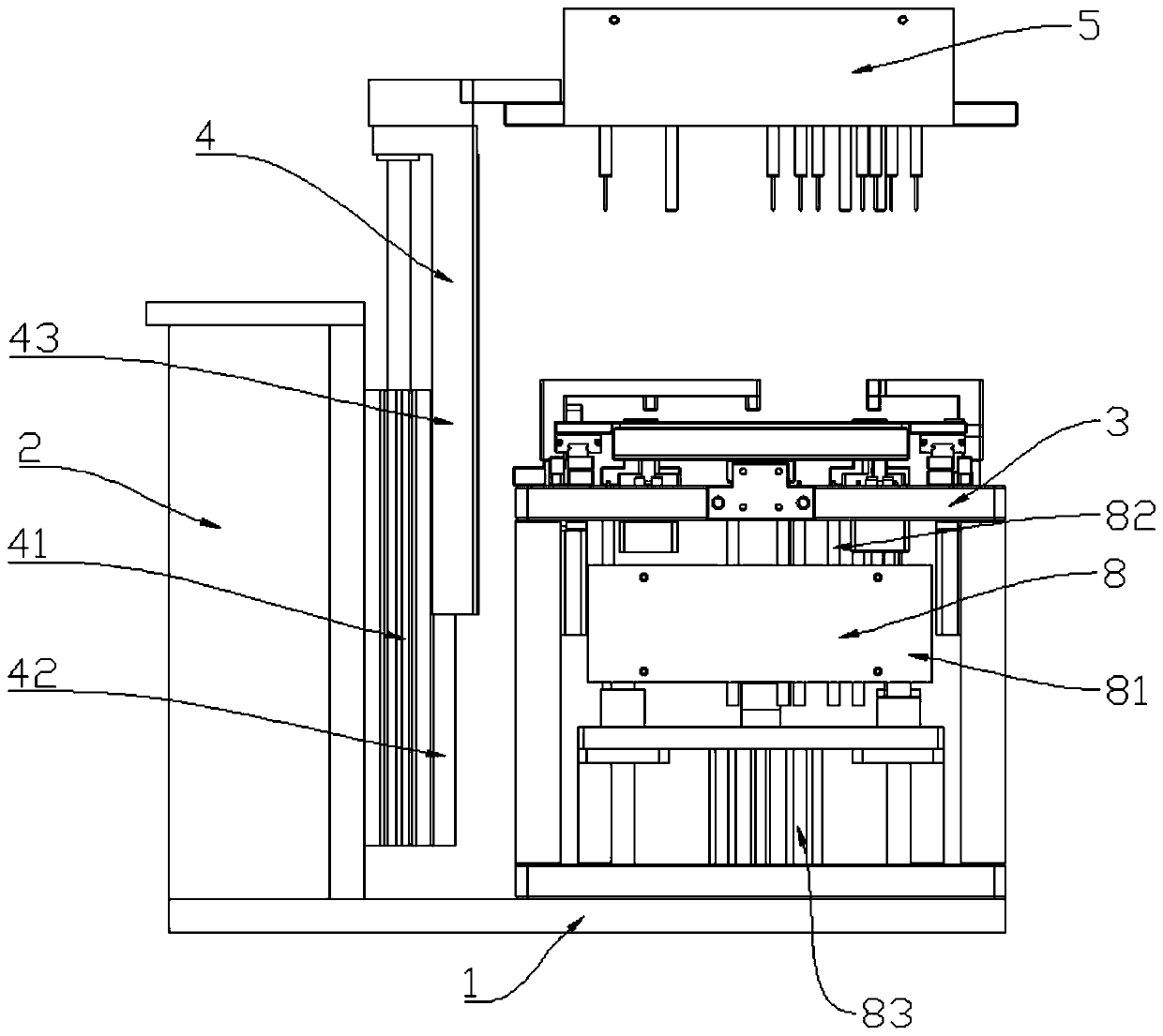

[0024] Such as Figure 1 to Figure 6 As shown, a broken knife detection device includes a base 1, on which a fixed box 2 and a workbench 3 are respectively arranged, and the side adjacent to the fixed box 2 and the workbench 3 is provided with a first lift Device 4, a first photoelectric detection device 5 is arranged above the first lifting device 4, the first photoelectric detection device 5 is controlled by the first lifting device 4 to rise and fall, and the components are detected by the first photoelectric detection device 5 The top is used for detection, and the left and right sides of the workbench 3 are respectively provided with a second photoelectric detection device 6 and an upper and lower fixing device 7, and the left and right sides of the parts are detected by the second photoelectric detection device 6. There are several ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com