Double-sided efficient polishing device for metal plate

A polishing device and plate technology, which is applied to grinding/polishing safety devices, grinding drive devices, metal processing equipment, etc. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

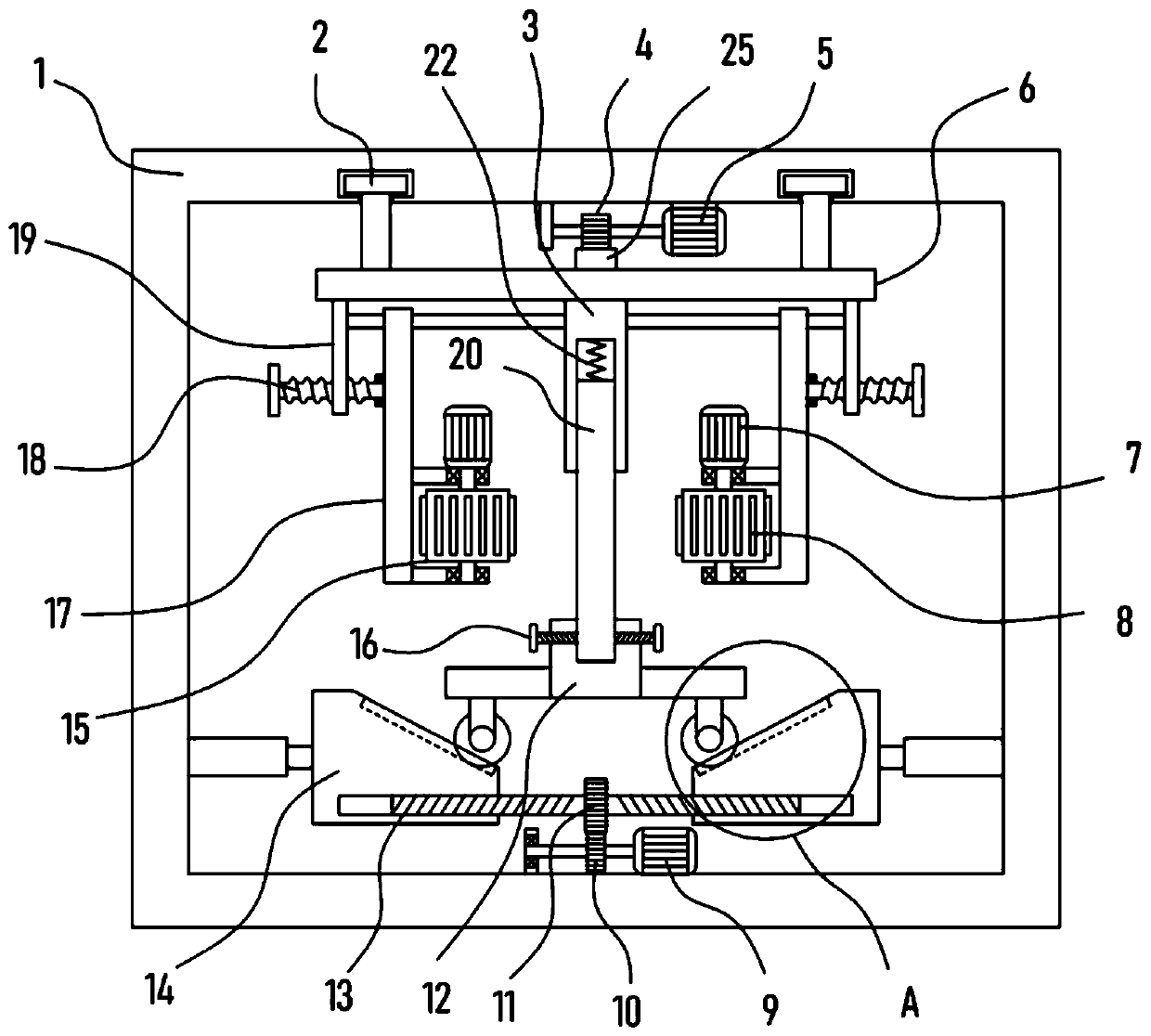

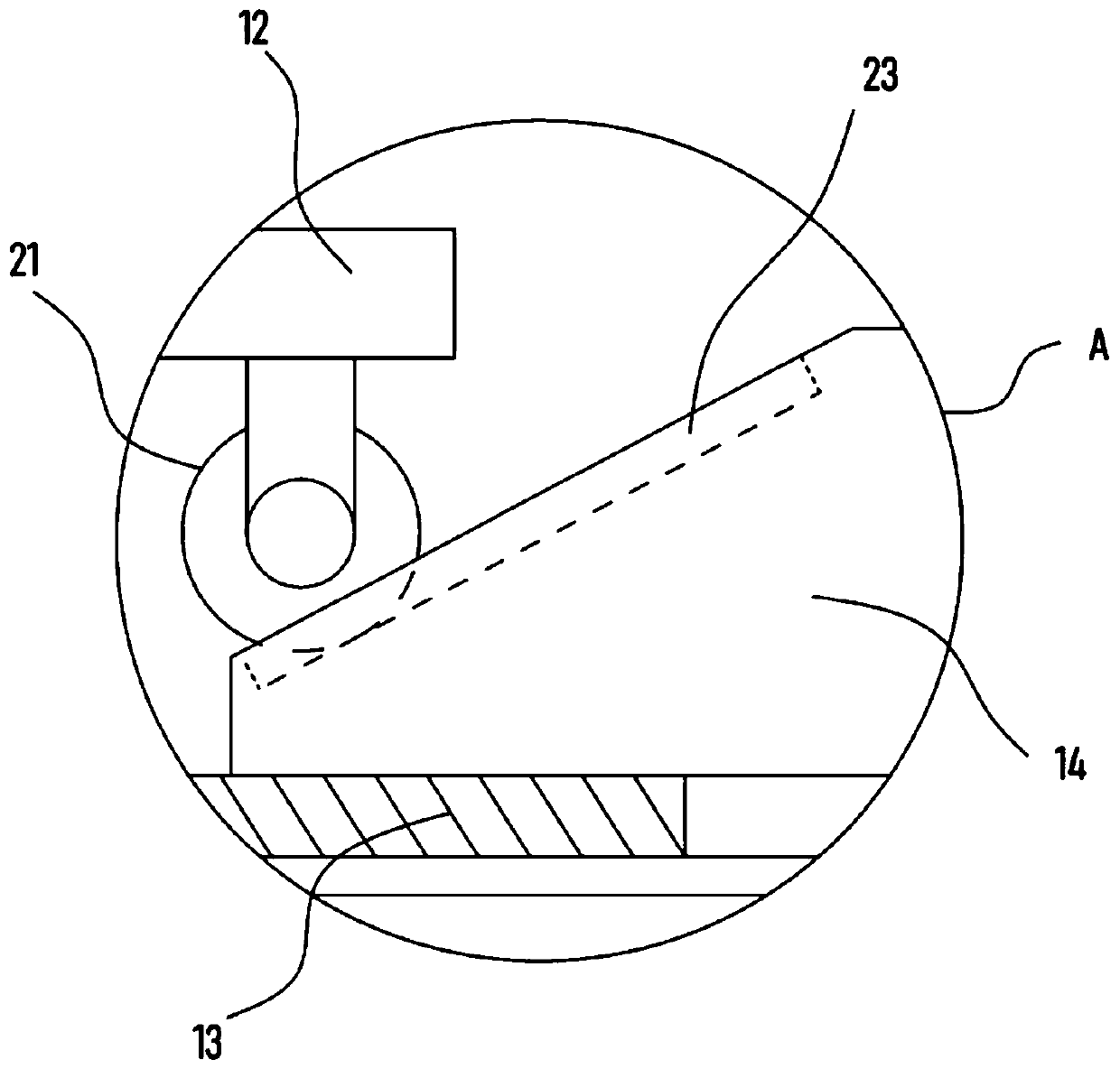

[0024] see Figure 1-5 , a double-sided high-efficiency polishing device for metal plate parts, comprising a support frame 1, a hanging plate 6 is fixed on the support frame 1, a guide block 2 slidingly embedded on the support frame 1 is fixed on the hanging plate 6, and the support frame 1 There are two laterally opposite wedge-shaped blocks 14 driven by the horizontal adjustment mechanism, and the clamping mechanism for fixing the metal plate 20 is abutted on the wedge-shaped blocks 14. The bottom of the hanging plate 6 is symmetrically provided with two connecting plates 17 The opposite sides of the two connecting plates 17 are provided with a grinding mechanism, and the bottom of the hanging plate 6 is provided with a spacing adjustment mechanism for adjusting the lateral movement of the connecting plates 17 .

[0025] When polishing the metal plate 20, first the metal plate 20 is clamped and fixed vertically by the clamping mechanism, and then the wedge-shaped block 14 is...

Embodiment 2

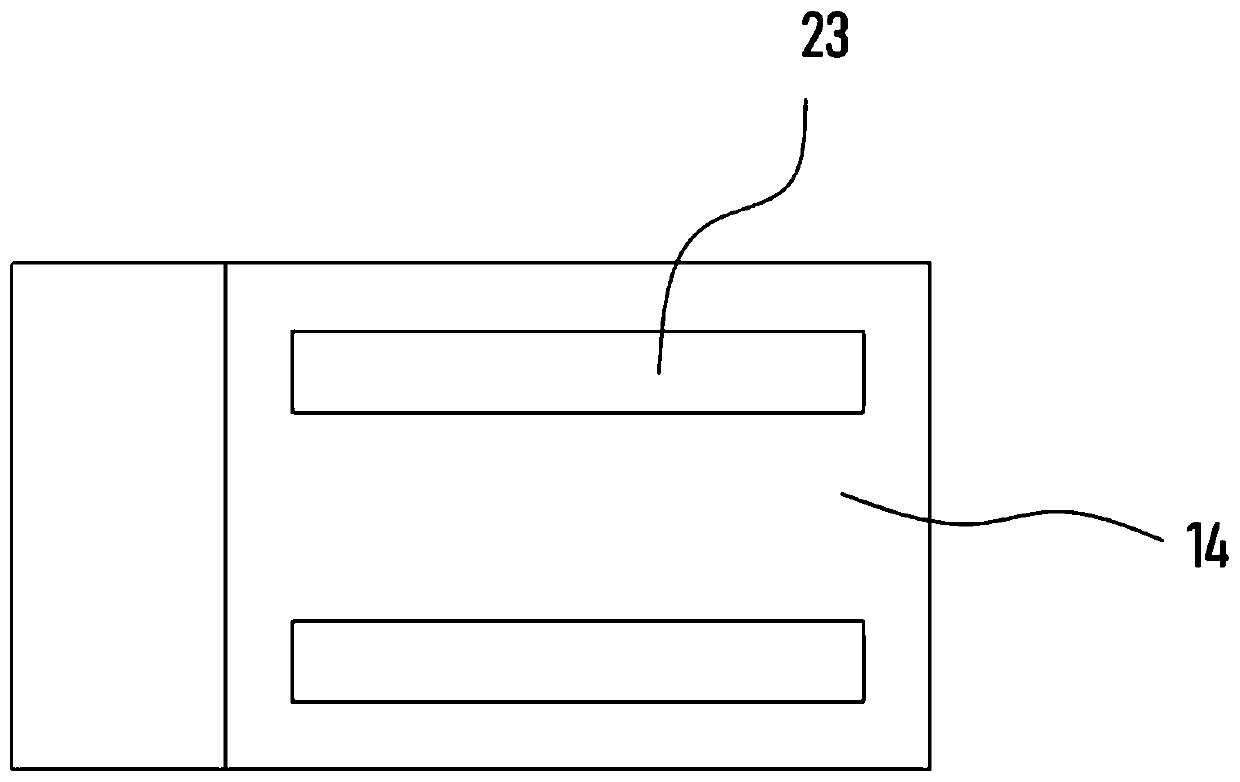

[0032] Due to the unevenness of the surface of the different metal plate parts 20, it is necessary to adjust the intensity of the grinding. For this reason, on the basis of Embodiment 1, the device is also provided with a distance adjustment mechanism, which includes vertically fixed on the hanging plate 6. The vertical plate 19 at the bottom, the threaded connection on the vertical plate 19 is provided with the threaded rod 18 pivotally connected on the connecting plate 17, the grinding mechanism includes a grinding roller 15 driven by the polishing motor 7, and the circumferential direction of the grinding roller 15 is There are several grinding convex strips 8 evenly and fixedly installed.

[0033] Through the above settings, the rotating threaded rod 18 can drive the connecting plate 17 to move laterally, so that the pressing force between the grinding protruding strip 8 and the metal plate 20 in the grinding mechanism can be adjusted to realize the required polishing proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com