Conveying type automatic sand-blasting machine

A sandblasting machine and conveying technology, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., can solve the problem of poor separation of dust, workpiece debris and sand materials, and low sand recycling rate , Conveying workpieces with low efficiency and other issues, achieving good dust removal effect, avoiding dust pollution in the air, and improving conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

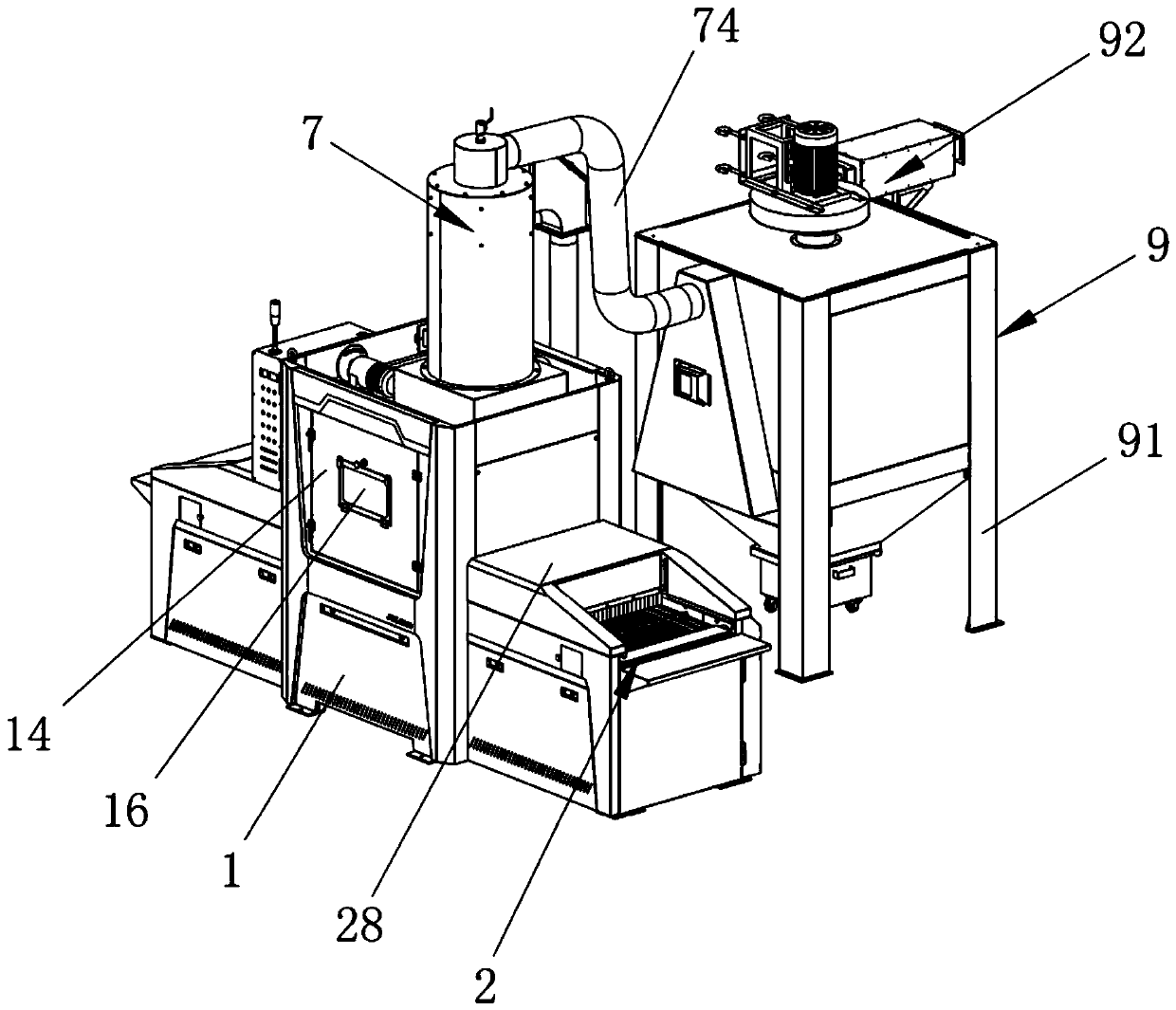

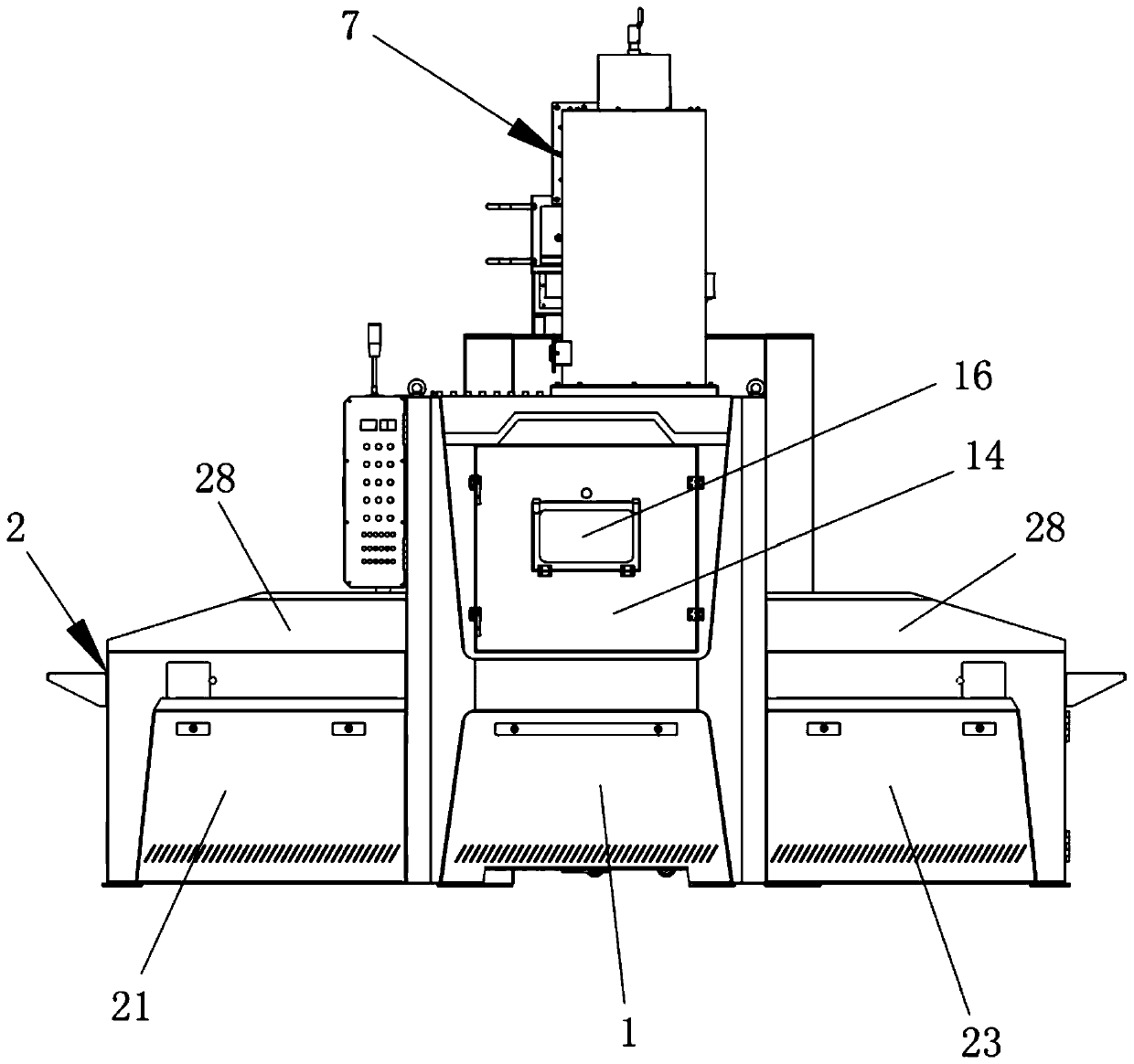

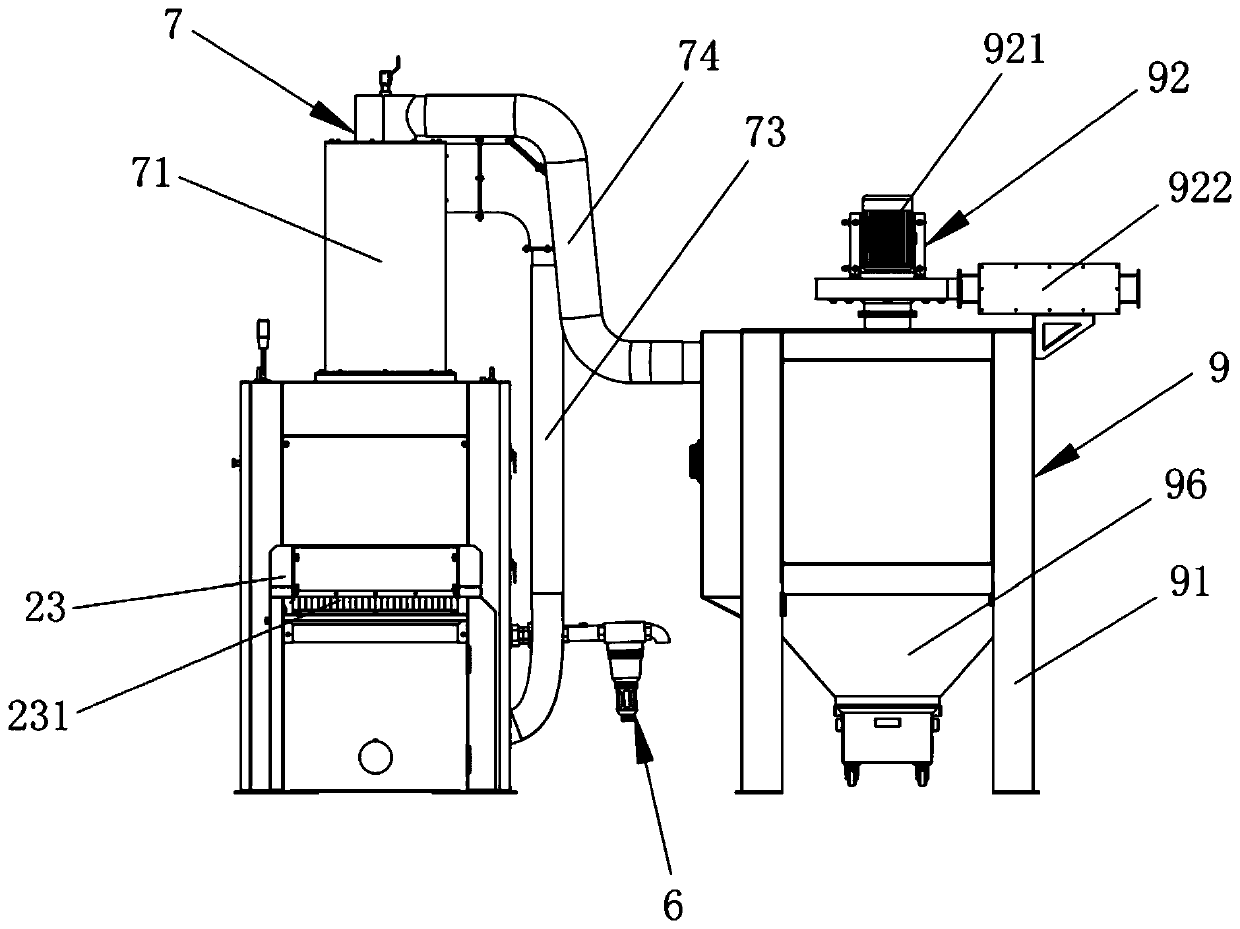

[0040] like Figure 1 to Figure 17 As shown, a conveying type automatic sandblasting machine provided by the present invention includes a sandblasting mechanism and an impurity removal mechanism 9 communicated with the sandblasting mechanism. The sandblasting chamber 11 in the frame 1, the conveying device 2 that is arranged on the sandblasting frame 1 and is used to input and output the workpiece into and out of the sandblasting chamber 11, is movable in the sandblasting chamber 11 and is used to carry out the workpiece transported by the conveying device The spray gun device 4 of sandblasting treatment, the air pressure supply device 6 for providing air pressure to the spray gun device 4, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap