Coal seam crushed coal reducing cutting device

A cutting device and coal seam technology, applied in the direction of cutting machinery, slitting machinery, earthwork drilling and mining, etc., can solve the problem that the broken coal cannot be gathered together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

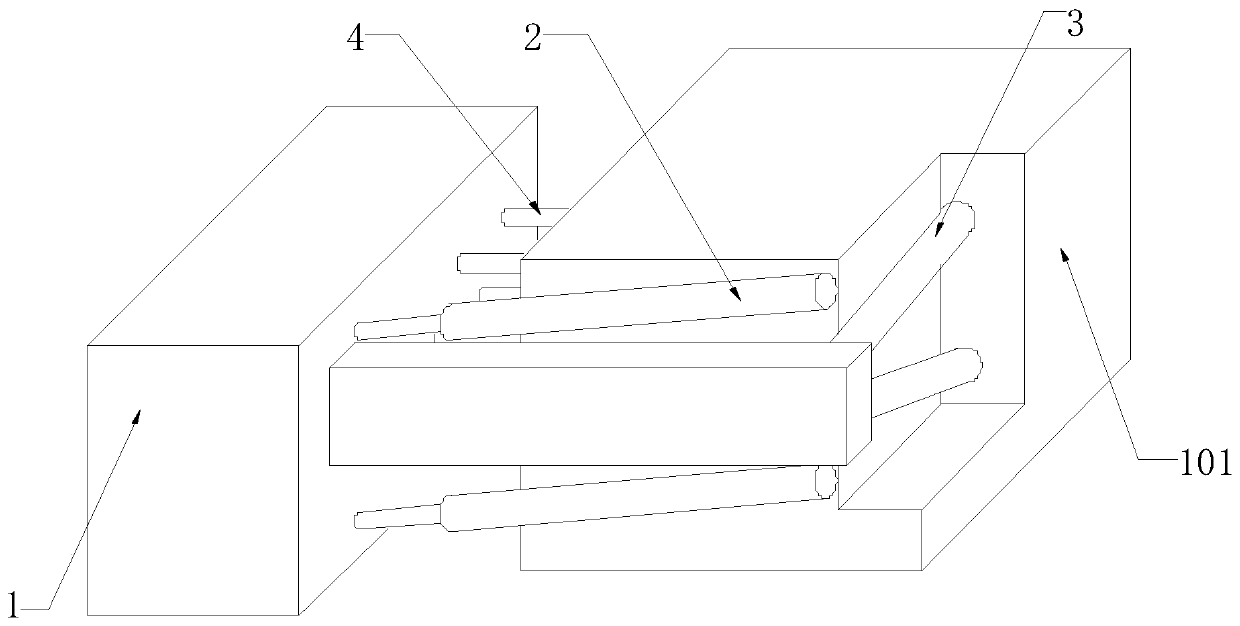

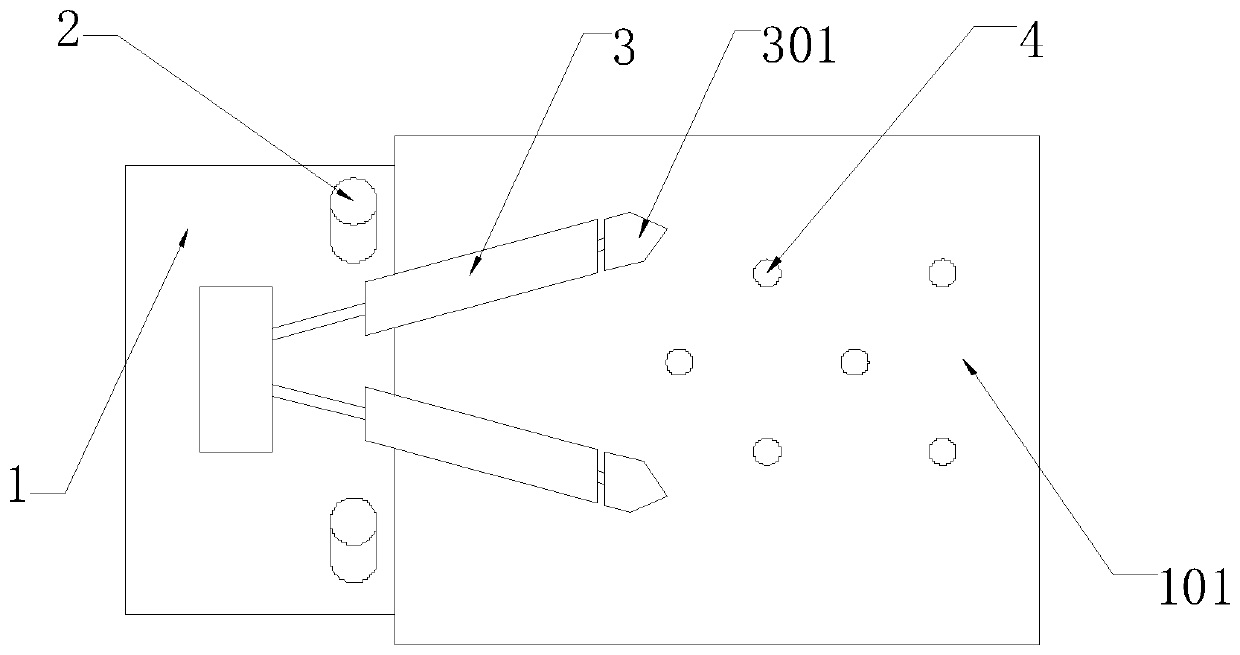

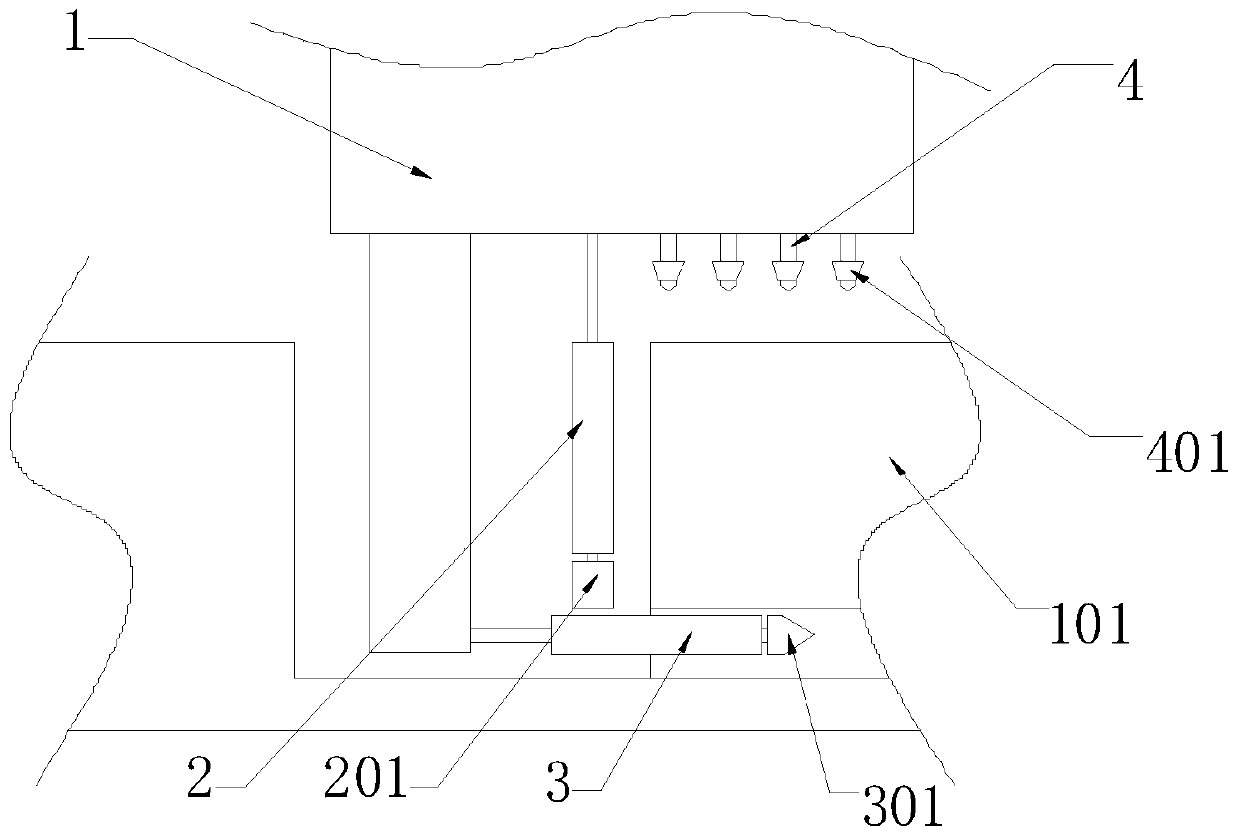

[0029] as attached figure 1 to attach Figure 8 Shown:

[0030] The invention provides a coal seam less broken coal cutting device, including: cutting machine 1, coal seam 101, transverse cutting rod 2, connecting head 201, return plate 202, diverter fan 203, water delivery plate 204, side cutting rod 3, dredging Drill 301, pulling rod 4, opening disc 401, driving plate 402, inserting rod 403, rotating tooth 404, side inserting rod 405 and transmission rod 5; A horizontal cutting rod 2 is arranged on one side, and a connecting head 201 is arranged on one side of the horizontal cutting rod 2, and a return plate 202 is arranged on one end of the connecting head 201, and a diverter fan 203 is arranged on the surface of the A water delivery tray 204 is provided, one end of the transverse cutting rod 2 is provided with a side cutting rod 3, one end of the side cutting rod 3 is provided with a dredging drill 301, one side of the cutting machine 1 is provided with a pulling rod 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com