Ceramic tile perforating device for building construction

A technology for building construction and tiles, which is applied in the field of tile opening devices for building construction, and can solve the problems of skewed holes, broken tiles, and inclinations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

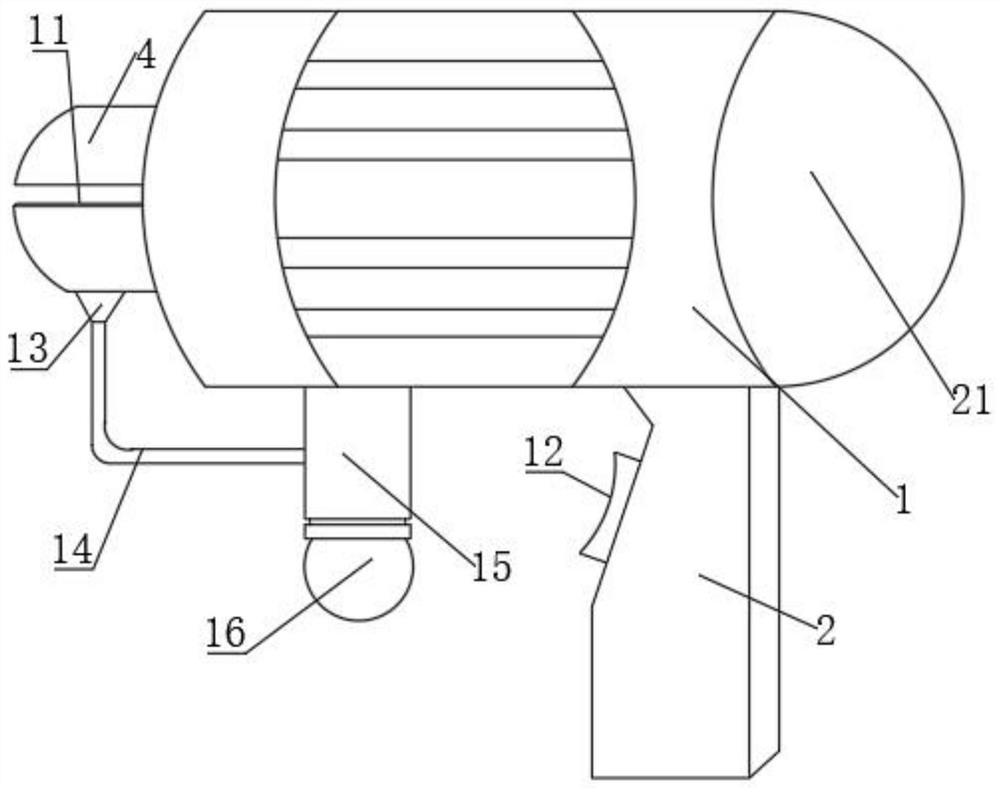

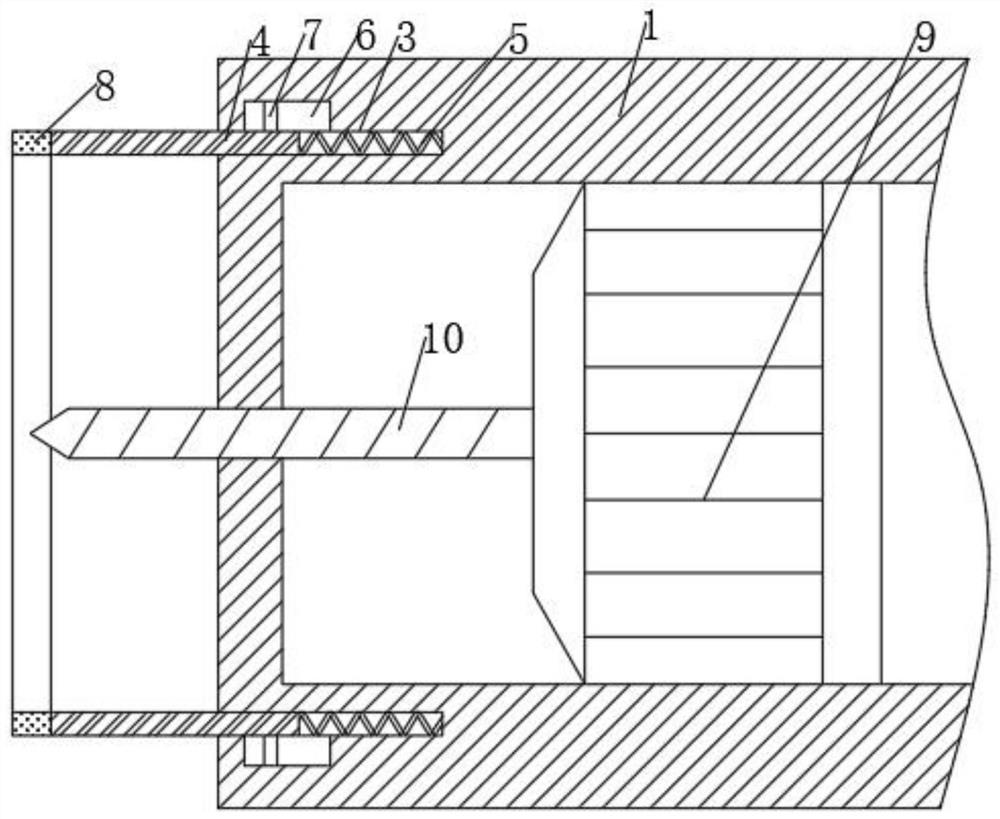

[0021] refer to Figure 1-2 , a ceramic tile hole opening device for building construction, comprising a housing 1, a ring groove 3 is opened on one side of the housing 1, an alignment cylinder 4 is slidably connected in the ring groove 3, and a spring 5 is fixed in the ring groove 3 by bolts, The outer side of the spring 5 and the alignment cylinder 4 are fixedly connected by bolts, the outer side of the alignment cylinder 4 is bonded with a rubber ring 8, the front end of the alignment cylinder 4 is provided with an opening 11, and the side of the housing 1 away from the alignment cylinder 4 is fixed by bolts There is a rear cover 21 , an opening mechanism is arranged inside the casing 1 , and a dust collection mechanism is arranged at the bottom of the casing 1 .

[0022] In the present invention, the top and bottom of the annular groove 3 are provided with two chute 6 symmetrically, and a slider 7 is slidably connected in the chute 6, and the two sliders 7 are respectively...

Embodiment 2

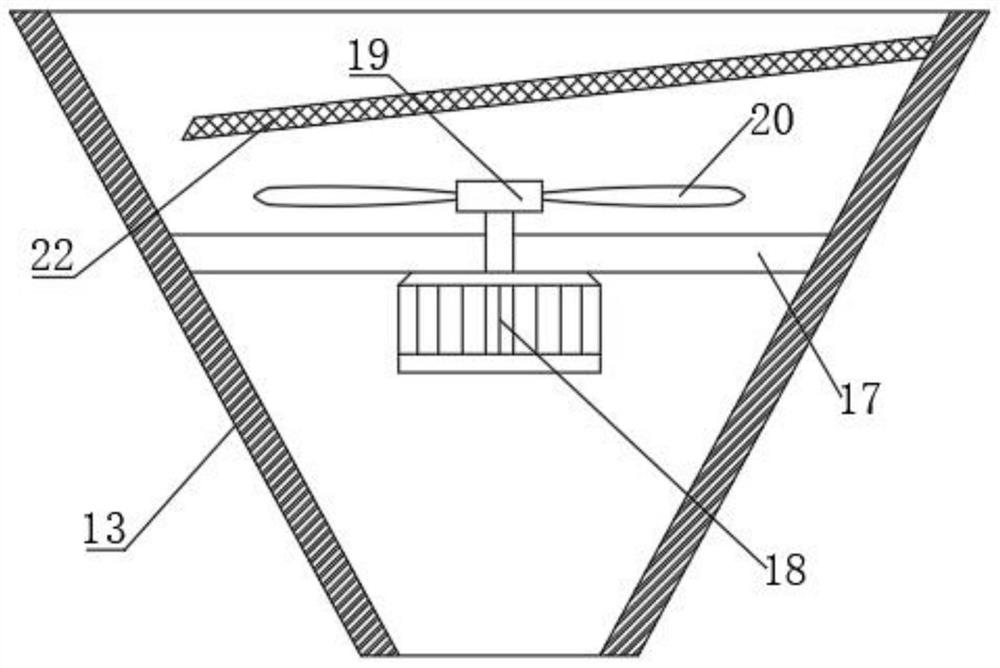

[0025] refer to Figure 1-3 , a ceramic tile opening device for building construction, the dust collection mechanism is fixed with a collection pipe 15 at the bottom of the housing 1 by bolts, the bottom of the collection pipe 15 is threaded with a dust collection bag 16, and the bottom of the alignment cylinder 4 is fixed with bolts Dust collection pipe 13, the dust collection pipe 13 is set as a hollow circular platform structure, the same hose 14 is connected between the collection pipe 15 and the dust collection pipe 13, and the interior of the dust collection pipe 13 is fixed with a fixed rod 17 by bolts, and the fixed rod 17 The bottom is fixed with a second motor 18 by bolts, the output shaft of the second motor 18 is connected with a sleeve 19, the outer wall of the sleeve 19 is fixed with a plurality of fan blades 20 distributed in an annular array by bolts, and the inner wall of one side of the dust collection pipe 13 is connected by bolts. A net plate 22 is fixed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com