A metering platform for alloy powder addition in alloy smelting

An alloy powder and alloy technology, applied in the field of alloy powder metering platform and alloy smelting alloy powder addition metering platform, can solve the problems of poor safety, low efficiency, inability to weigh and measure, and achieve accurate addition metering, high efficiency and easy operation. The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

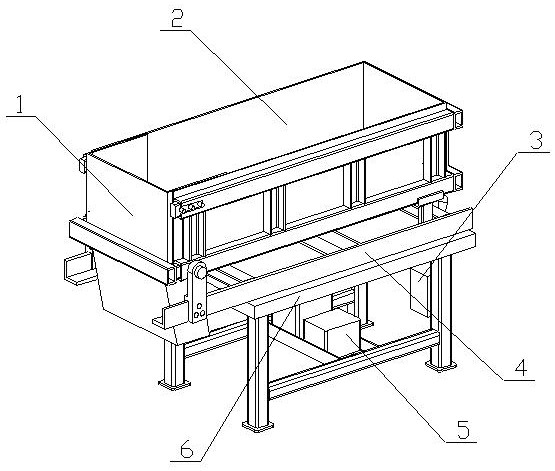

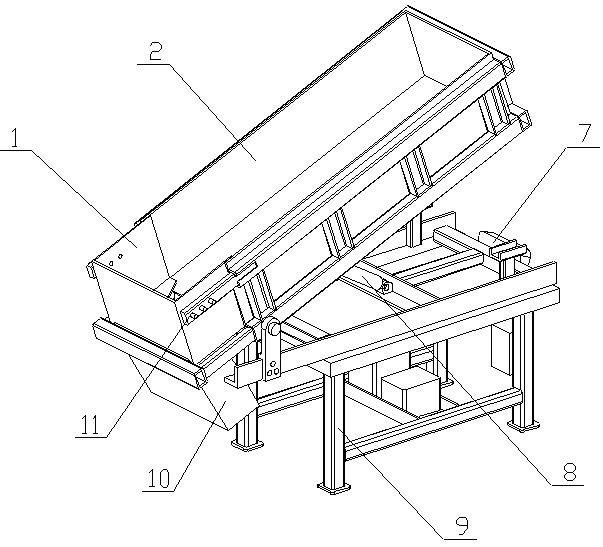

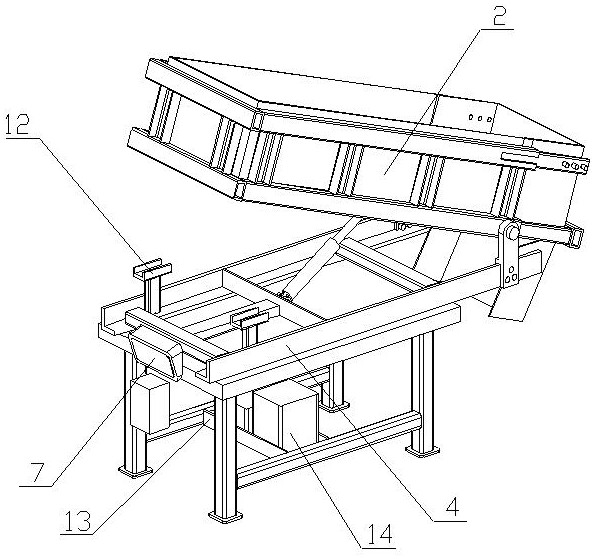

[0021]An alloy smelting alloy powder adding metering platform of the present invention is realized in this way, consisting of a side box door (1), a box body (2), a control box (3), a support plate (4), a hydraulic oil tank (5), and a platform scale ( 6), digital display (7), hydraulic cylinder (8), bottom support bracket (9), guide box (10), sliding rod (11), support frame (12), fixed plate (13), hydraulic pump (14), opening slot (15), supporting beam (16), vertical rod (17), hinged shaft (18), lower supporting rod (19), beam (20), blanking port (21), hinged arm ( 22), reinforcing rod (23), oil cylinder fixing rod (24) and connecting beam (25), the platform scale (6) is placed on the bottom support bracket (9), and one end of the platform scale (6) is equipped with a display weighing The digital display (7), the fixed plate (13) is placed on the bottom support bracket (9), and is located below the platform scale (6), the hydraulic oil tank (5) is placed on the fixed plate (13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com