Extractor hood and panel drive mechanism for same

A range hood, panel-driven technology, applied in the direction of oil fume removal, application, household stoves, etc., can solve the problems that the panel cannot be too wide, the structure is complex, and affect the user's operating space, and achieve the effect of high user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

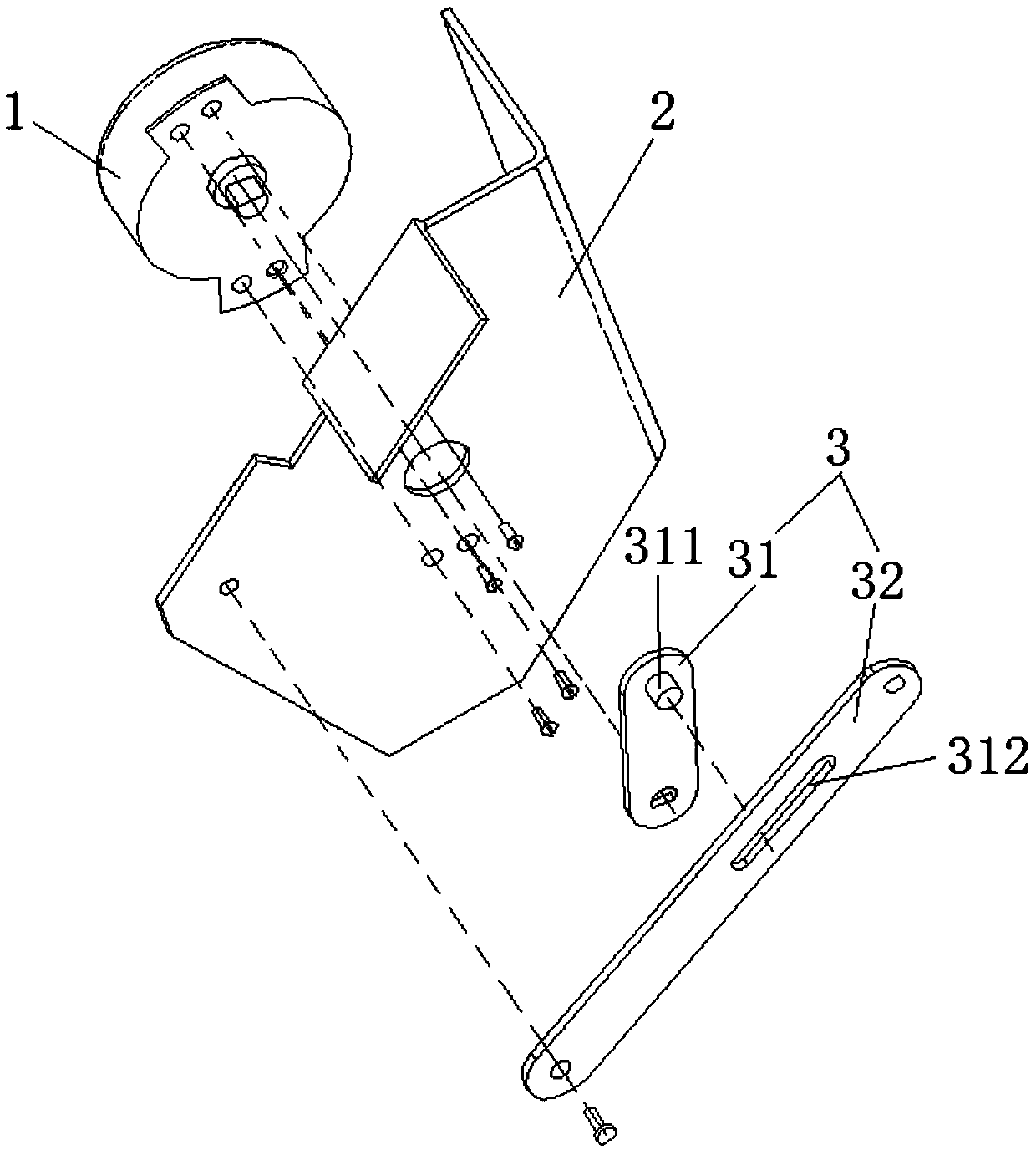

[0028] Embodiments of the present invention provide a panel drive mechanism for range hoods, such as figure 1 As shown, it includes a drive assembly 1, a fixed bracket 2 and a connecting rod transmission assembly 3, the drive assembly 1 is arranged on the fixed bracket 2, and the output end of the drive assembly 1 is connected to the connecting rod transmission assembly 3 for driving the connecting rod transmission assembly 3 Swing back and forth.

[0029] The connecting rod transmission assembly 3 includes a driving connecting rod 31 and a driven connecting rod 32. One end of the driving connecting rod 31 is connected to the drive assembly 1, and the other end drives the driven connecting rod 32 to swing. One end of the driven connecting rod 32 is arranged on the fixed bracket 2, the other end is connected with the range hood panel, so that the drive assembly 1 drives the active link 31 to swing, and the active link 31 drives the driven link 32 to swing, thereby realizing the...

Embodiment 2

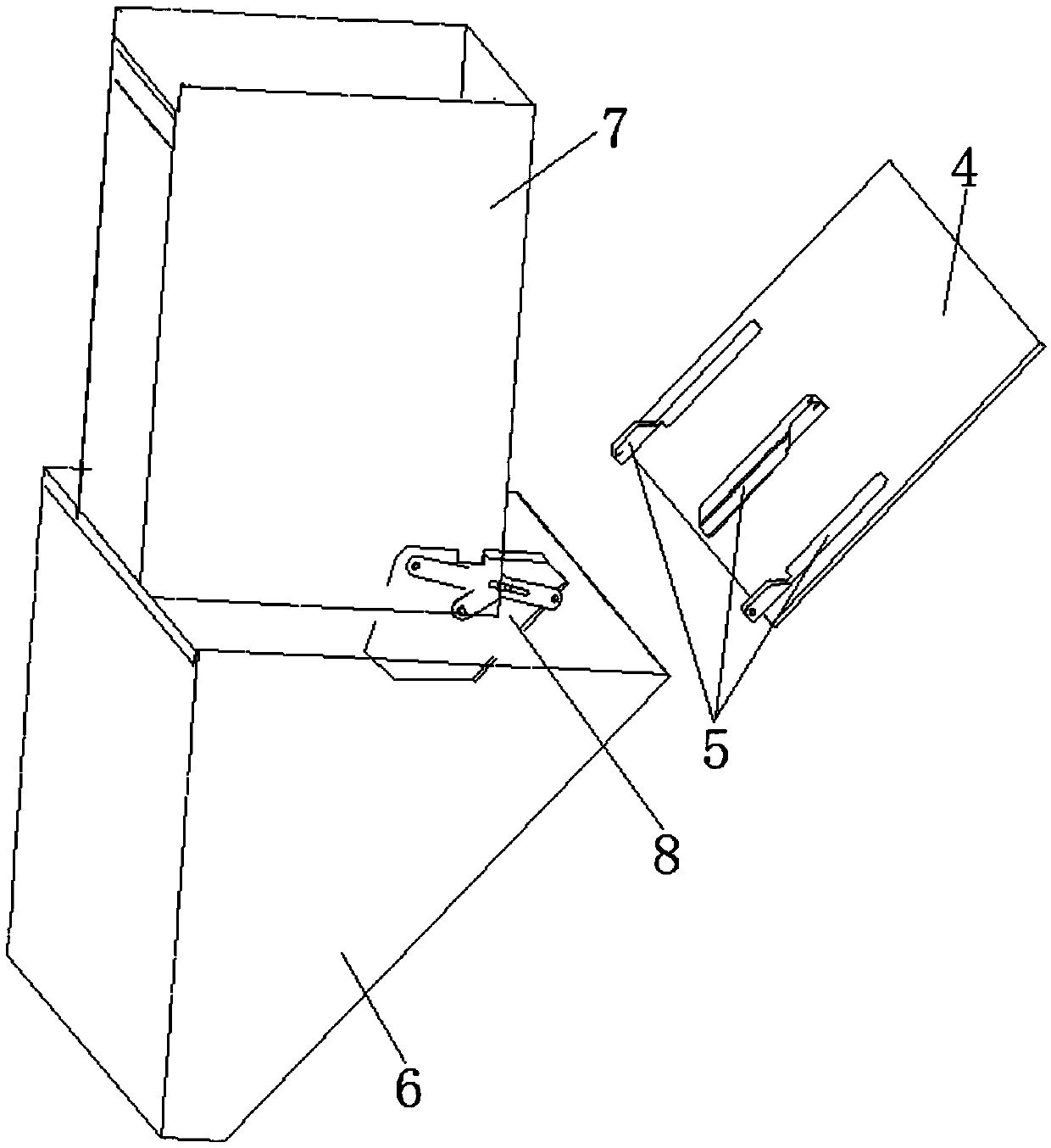

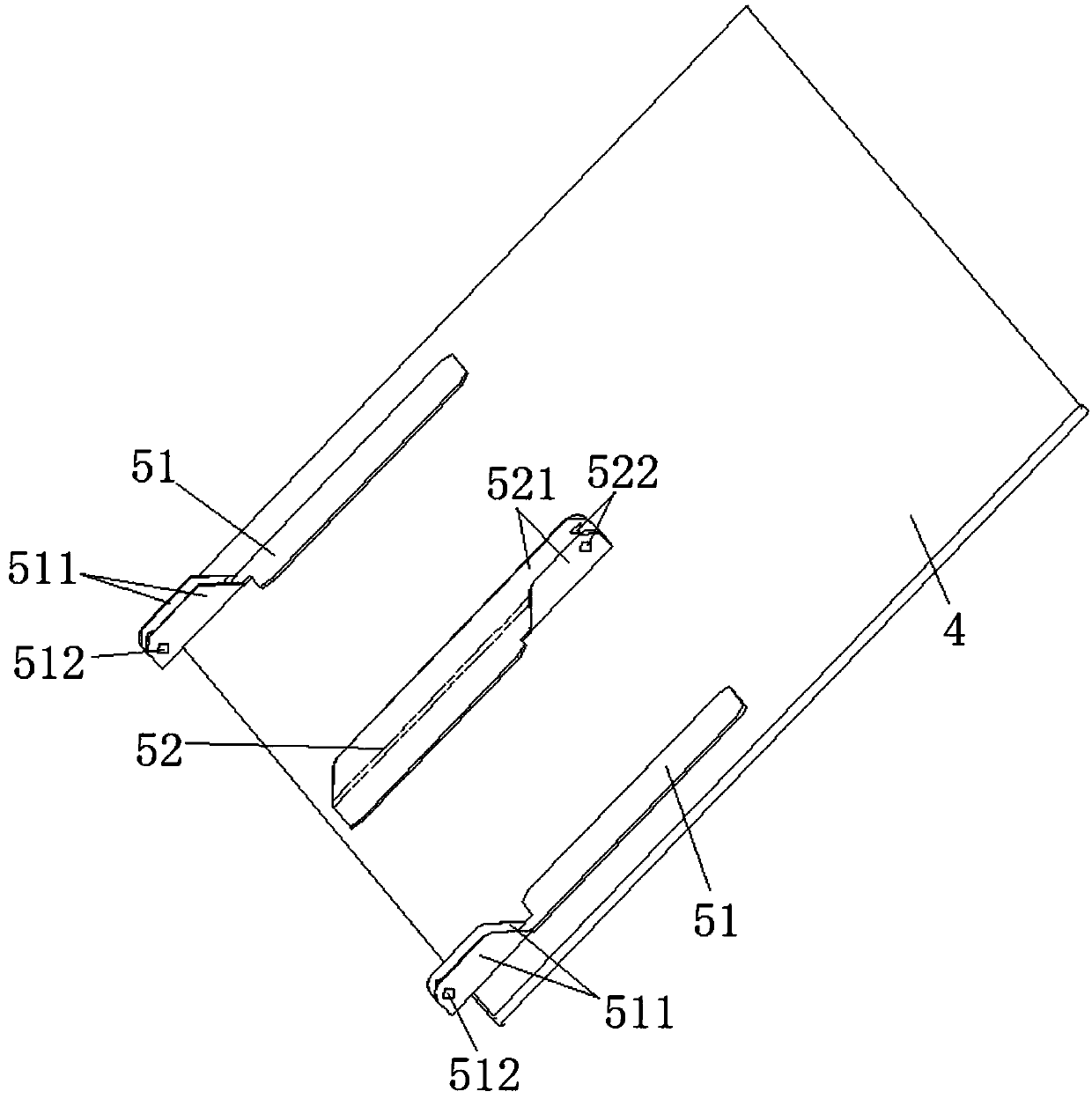

[0033] Embodiment 2 of the present invention provides a range hood, such as Figure 2-5 As shown, it includes a panel 4, a bracket assembly 5, a smoke collecting hood 6, an air duct cover 7 and a panel drive mechanism 8, the panel driving mechanism 8 is arranged in the smoke collecting hood 6, and the air duct cover 7 is located on the top of the smoke collecting hood 6 , the panel 4 is arranged at the air inlet of the smoke collecting hood 6 , the bracket assembly 5 is arranged on the panel 4 and connected with the panel driving mechanism 8 .

[0034] The panel driving mechanism 8 drives the panel 4 to move up and down through the bracket assembly 5 to realize opening or closing.

[0035] The panel driving mechanism 8 includes a drive assembly 1, a fixed bracket 2 and a link transmission assembly 3, the drive assembly 1 is arranged on the fixed bracket 2, and the output end of the drive assembly 1 is connected to the link transmission assembly 3 for driving the link transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com