A device and method for measuring parallelism of guide rails

A measurement device and measurement method technology, applied in the direction of measurement device, optical device, instrument, etc., can solve the problems of expensive equipment, low efficiency, technical level and other factors, and achieve the effect of high accuracy and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

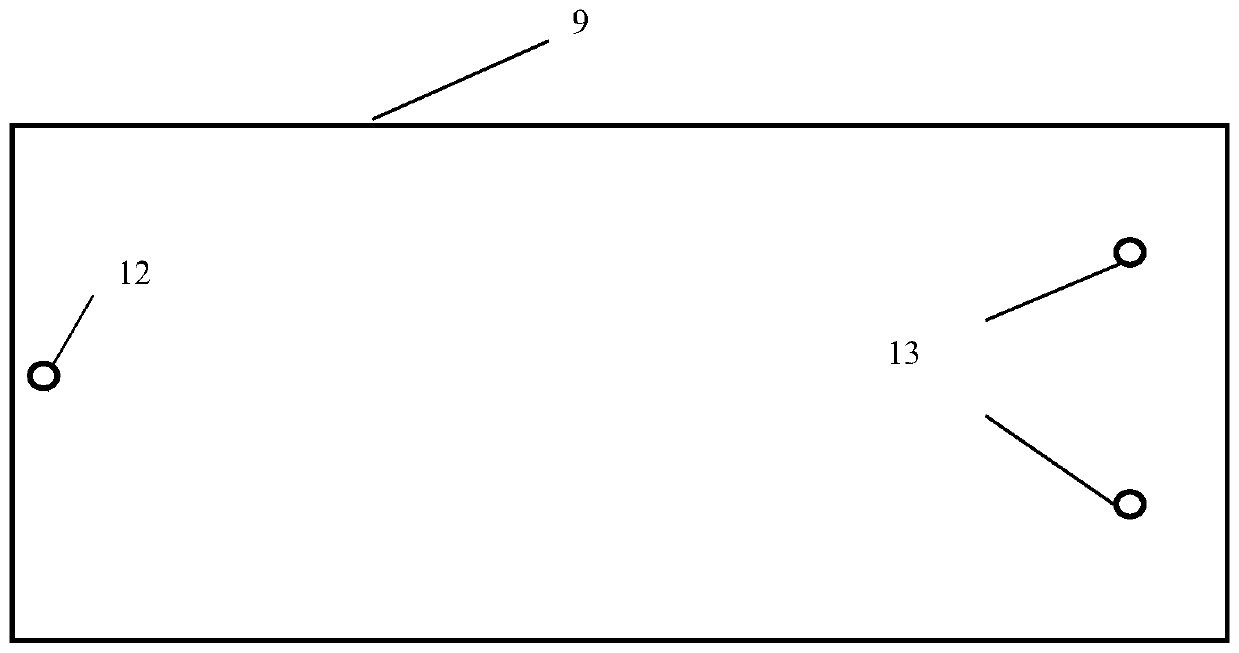

[0075] 1) Add auxiliary measuring points on the inner side of the guide rail

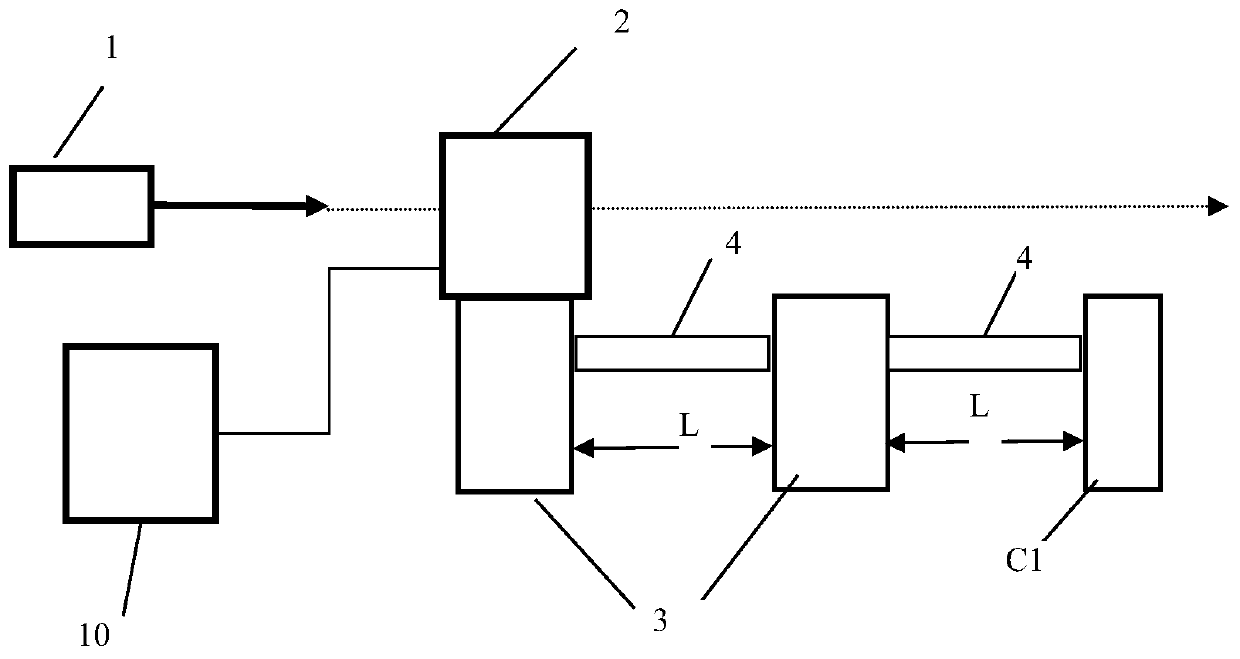

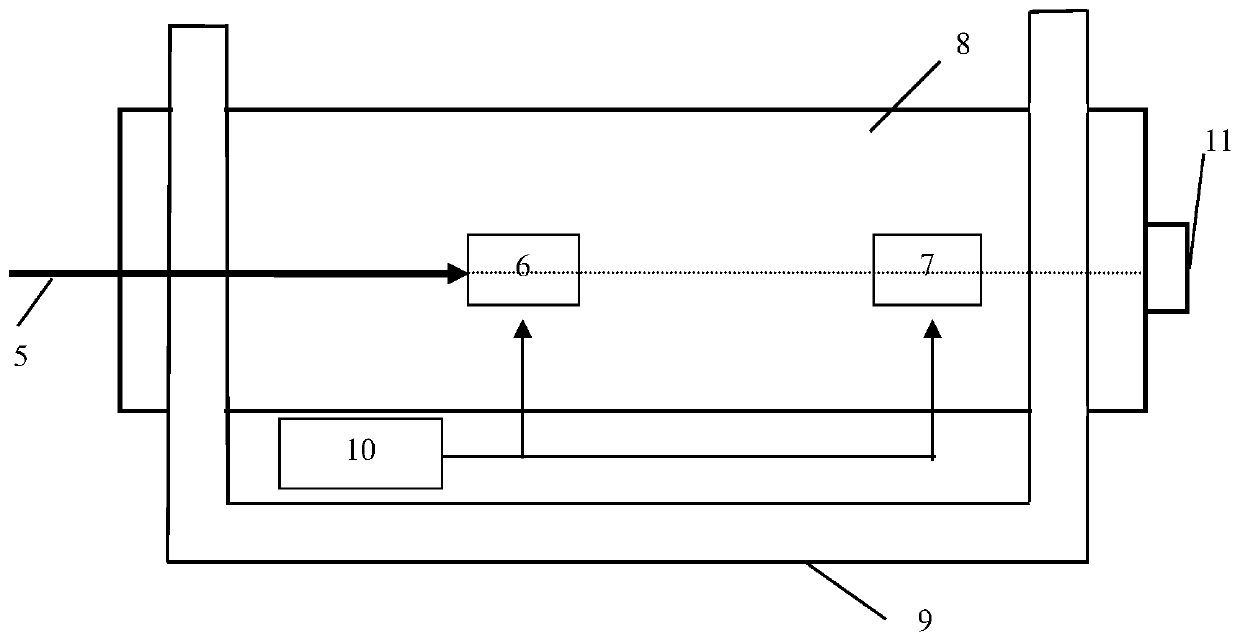

[0076] Such as Figure 5 As shown, the distance between the guide rail pairs is L, the auxiliary measurement point is arranged between the guide rails, and the distance between the auxiliary measurement point and the guide rail pair is

[0077] Such as Figure 6 As shown, the auxiliary measuring point is arranged on the outside of the guide rail, and the distance between the auxiliary measuring point and the guide rail pair is L, and the specific placement position of the auxiliary measuring point is determined by the length scale;

[0078] 2) Make a reasonable arrangement of measuring points on the guide rail pair

[0079] Carry out scribing on the guide rail, and the meter-shaped shape formed with auxiliary measuring points can be selected according to the actual situation. If the meter-shaped character cannot cover the entire guide rail, additional measuring points should be arranged on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com