A flexible flicking mechanism for separating waste cigarettes and shredded paper

A technology of waste cigarettes and silk paper, which is applied in the fields of application, tobacco, and paper cigarettes, etc., can solve the problems of waste of cut tobacco, generation of shredded paper, and lower quality of cut tobacco, so as to prevent shredding, avoid extrusion friction, and reduce waste. Effects of Force and Destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

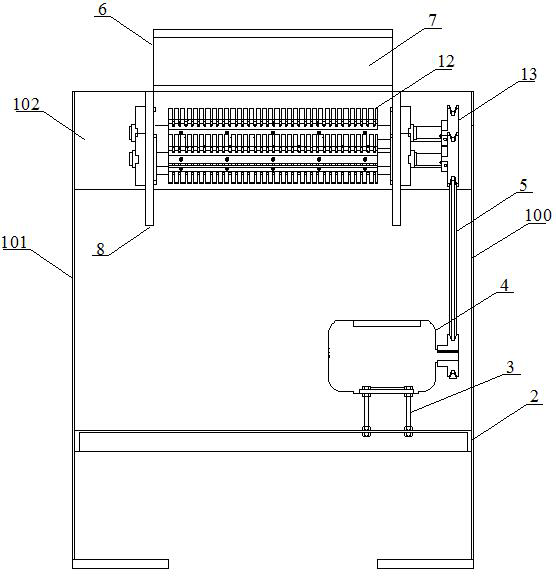

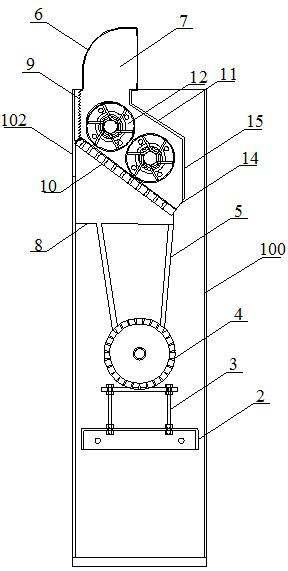

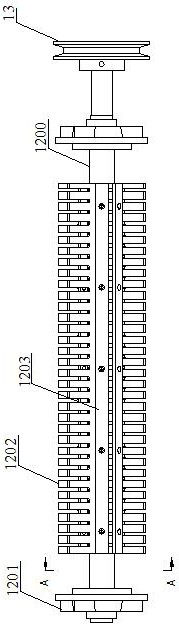

[0026] Such as Figures 1 to 5 As shown, a flexible flicking mechanism for the separation of waste cigarettes and shredded paper includes a shredded paper separation bin and a frame. The backboard 102 on the rear side and the vertical board 15 on the front side, the bottom ends of the left support board 101 and the right support board 100 are all fixed on the ground, and the back board 102 and the vertical board 15 are all vertically arranged on the left between the support plate 101 and the right support plate 100 and are fixedly connected with the upper part of the inner side of the left support plate 101 and the right support plate 100; Between the plate 9 and the vertical plate 15, a left fixed plate 8 and a right fixed plate are arranged symmetrically and vertically, and the front ends of the left fixed plate 8 and the right fixed plate are all connected with the inside of the vertical plate 15. The rear ends of the left fixing plate 8 and the right fixing plate are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com