Safety protection anti-collision semi-trailer fuel tank

A protective and anti-collision technology, applied in vehicle components, layout combined with internal combustion engine fuel supply, power plant, etc., can solve problems such as increased driver danger, fuel tank deformation, fire, etc., achieve good protection effect, avoid fuel tank Deformation and stability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

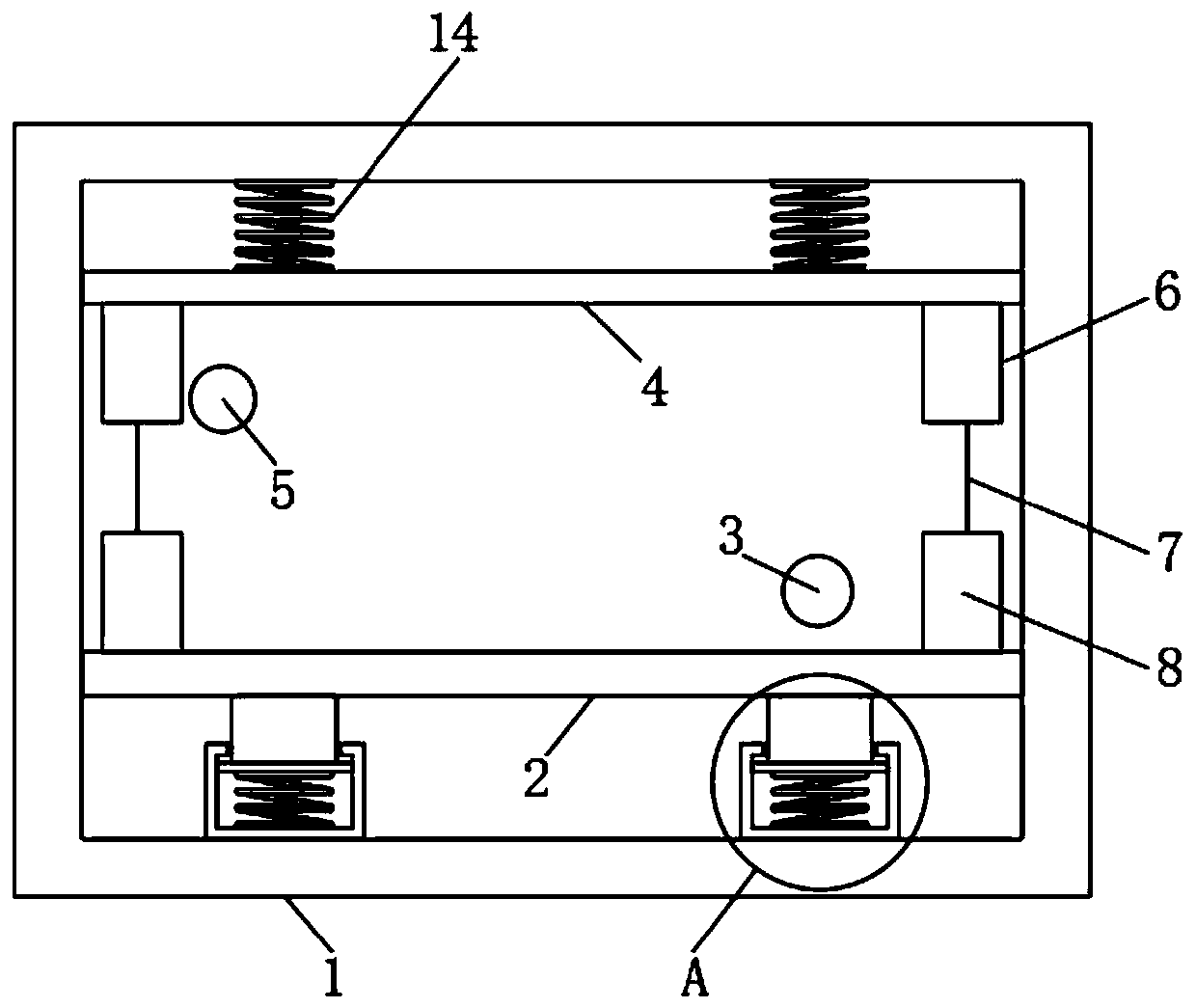

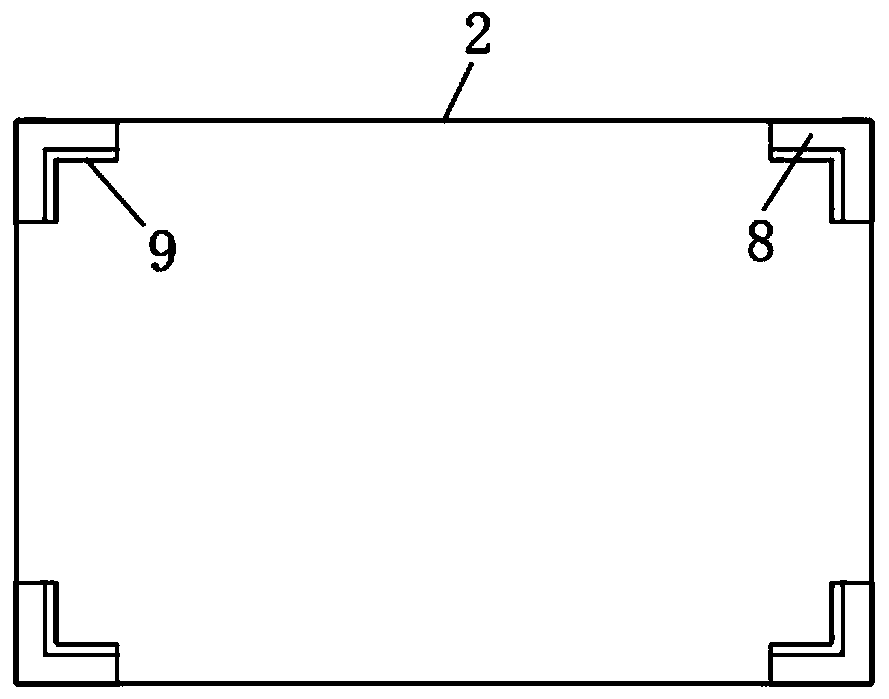

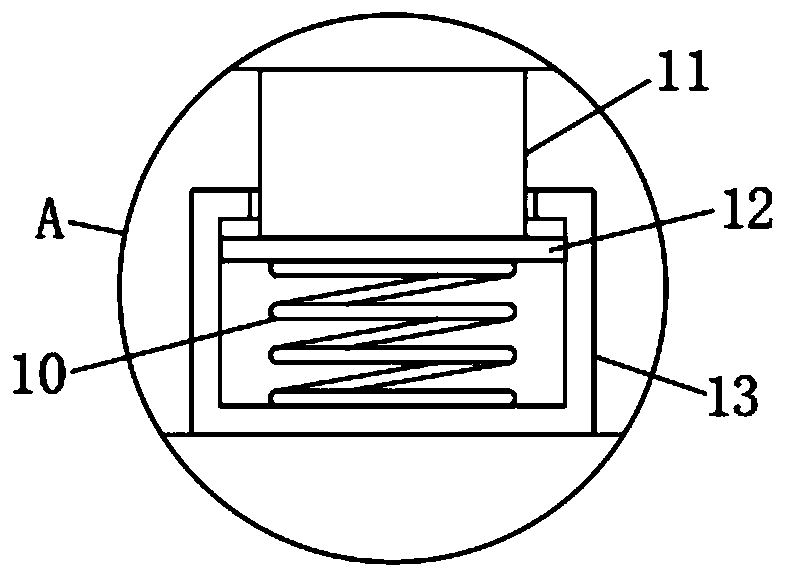

[0026] refer to Figure 1-4 , a fuel tank for an anti-collision semi-trailer with good safety and protection, comprising a tank body 1, a placement plate 2 that can move up and down is arranged inside the box body 1, a fuel tank 7 is arranged on the upper end of the placement board 2, and an outlet is arranged on the fuel tank 7. The oil port 3 and the oil inlet 5, the oil outlet 3 and the oil inlet 5 are all prior art, and will not be repeated here. The placement plate 2 is provided with a first limit mechanism, and the inside of the box body 1 A shock-absorbing mechanism is provided between the bottom and the lower end of the placement plate 2. A pressing plate 4 that can move up and down is provided inside the box body 1. The lower end of the pressing plate 4 is provided with a second limit mechanism. The upper end and the inner top of the box body 1 are elastically connected by the second compression spring 14, and the second compression spring 14 is respectively fixed wit...

Embodiment 2

[0033] refer to Figure 2-5, a fuel tank for an anti-collision semi-trailer with good safety and protection, comprising a tank body 1, a placement plate 2 that can move up and down is arranged inside the box body 1, a fuel tank 7 is arranged on the upper end of the placement board 2, and an outlet is arranged on the fuel tank 7. The oil port 3 and the oil inlet 5, the oil outlet 3 and the oil inlet 5 are all prior art, and will not be repeated here. The placement plate 2 is provided with a first limit mechanism, and the inside of the box body 1 A shock-absorbing mechanism is provided between the bottom and the lower end of the placement plate 2. A pressing plate 4 that can move up and down is provided inside the box body 1. The lower end of the pressing plate 4 is provided with a second limit mechanism. The upper end and the inner top of the box body 1 are elastically connected by the second compression spring 14, and the second compression spring 14 is respectively fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com