Gate valve convenient to regulate and control

A plug-in valve, valve body technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problem of unclear opening and closing degree of valve plate, inability to understand the opening and closing degree of valve plate from the remote end, etc., and achieve intuitive opening and closing. The effect of closing degree and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

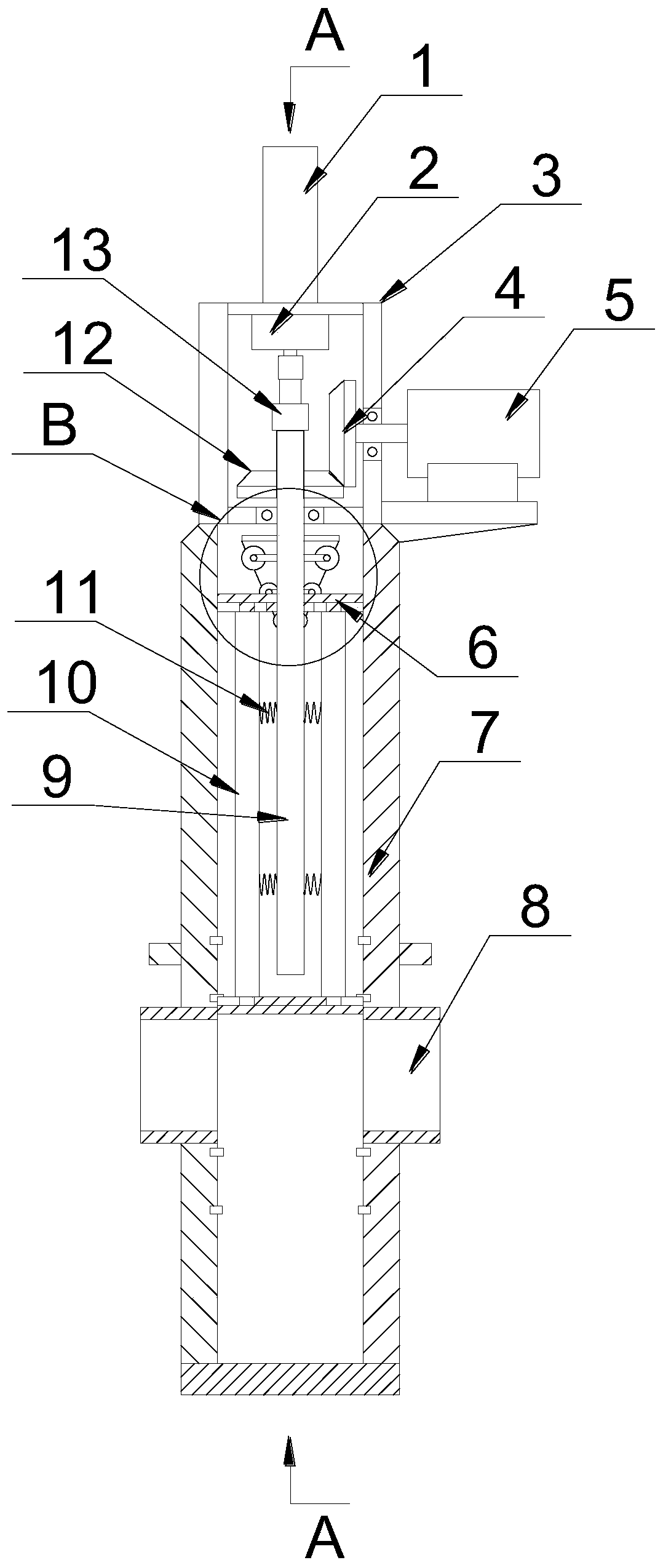

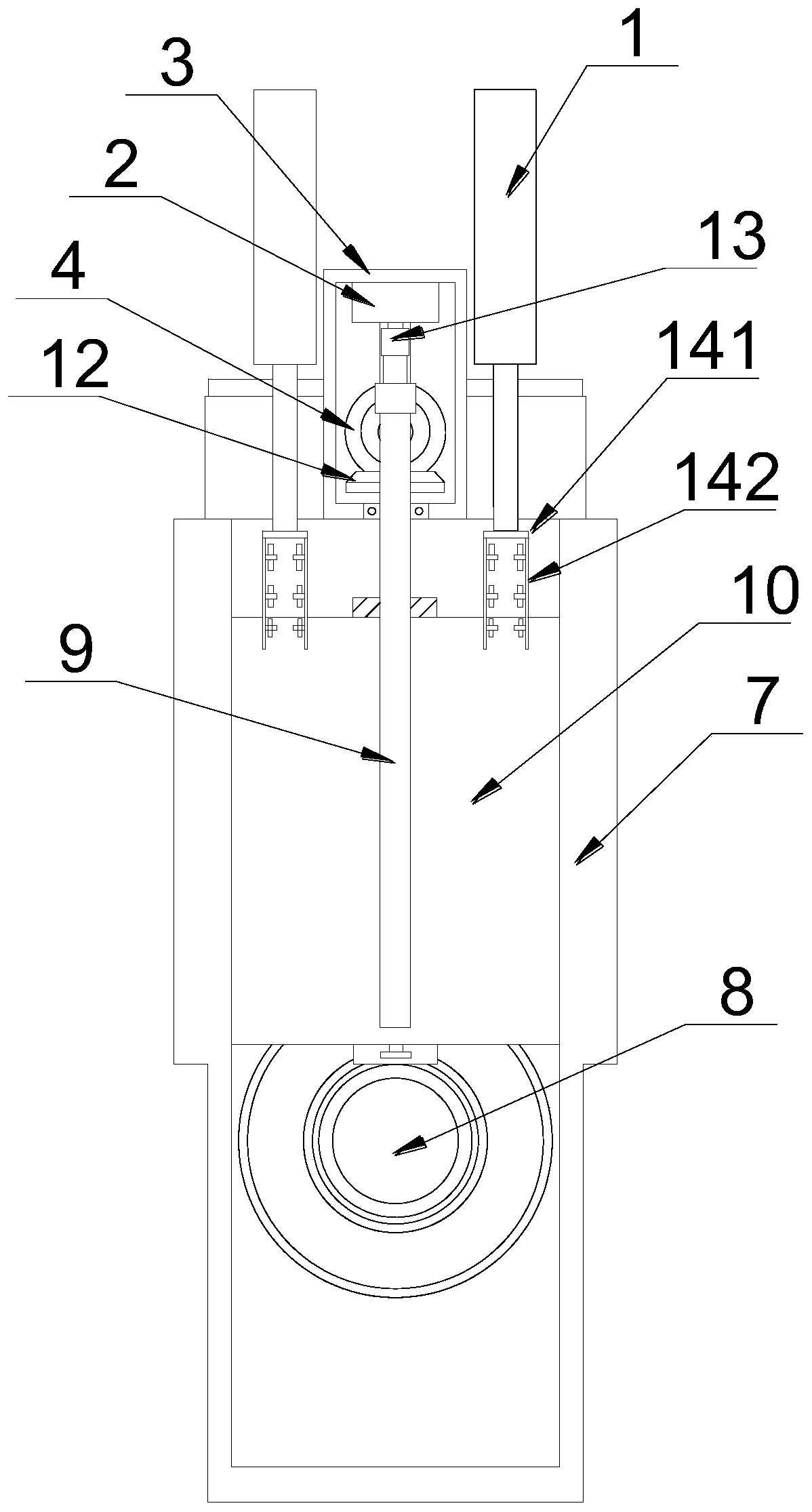

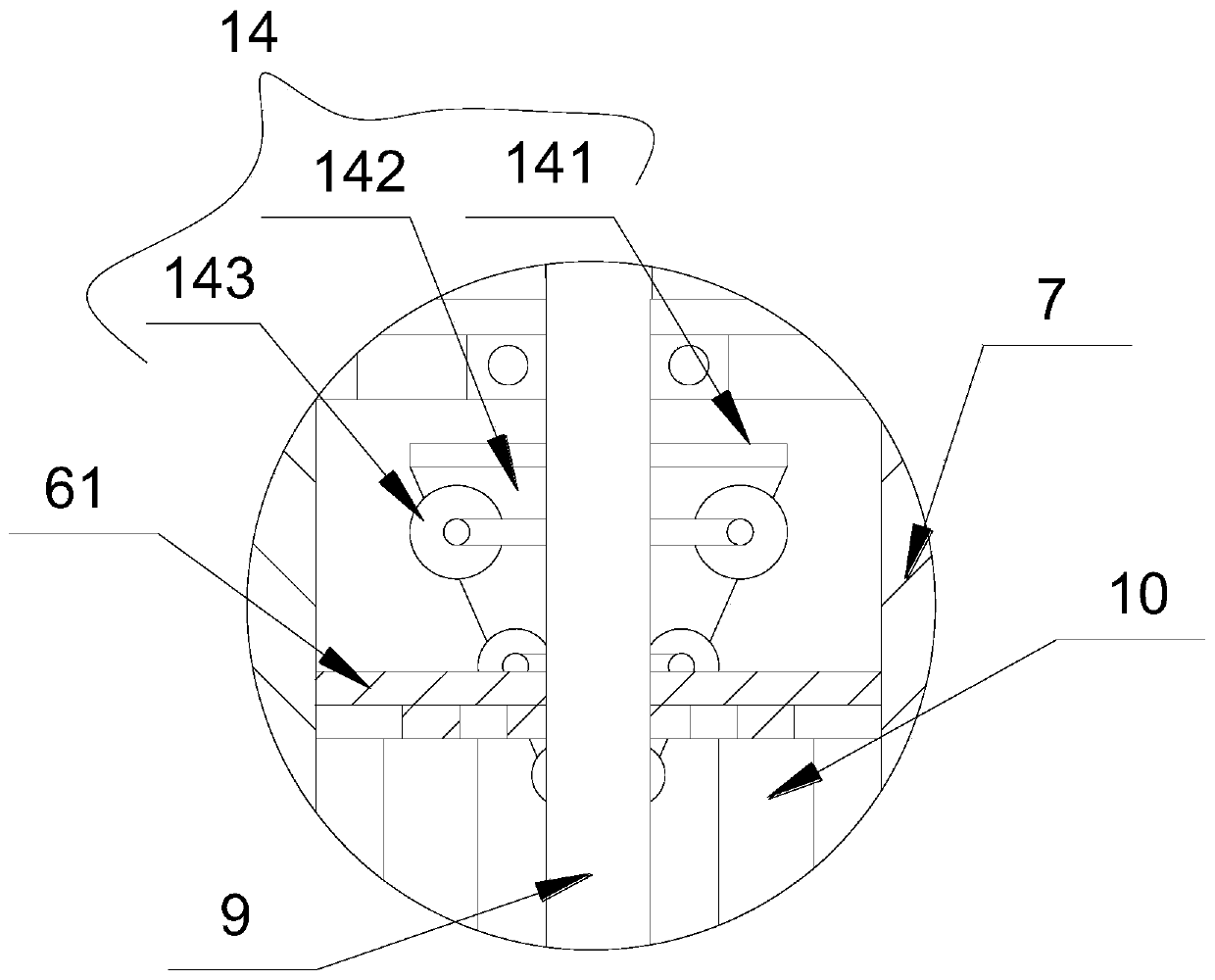

[0030] see Figure 1~3 , a plug-in valve that is easy to control, including a valve body 7, a through hole 8 is opened on the valve body 7, a valve plate 10 is arranged in the valve body 7, and a valve body 7 is provided with a transmission connection with the valve body 7 at the upper end of the valve body 7 Drive mechanism one, described drive mechanism one comprises the motor 5 that is positioned at the upper end of valve body 7 and is arranged laterally, and the output end of described motor 5 is provided with bevel gear-4, and described bevel gear-4 is meshed with can be wound around the vertical shaft Rotating bevel gear 2 12, said bevel gear 2 12 is fixedly sleeved with a screw 9, the lower end of the screw 9 extends into the valve body 7 and is threadedly connected with a transmission member 6, and the transmission member 6 is fixed to the valve plate 10 Connected, the upper end of the screw rod 9 extends out of the bevel gear 2 12 and is provided with a coupling 13, t...

Embodiment 2

[0034] see Figure 1~3, a plug-in valve that is easy to control, including a valve body 7, a through hole 8 is opened on the valve body 7, a valve plate 10 is arranged in the valve body 7, and a valve body 7 is provided with a transmission connection with the valve body 7 at the upper end of the valve body 7 Drive mechanism one, described drive mechanism one comprises the motor 5 that is positioned at the upper end of valve body 7 and is arranged laterally, and the output end of described motor 5 is provided with bevel gear-4, and described bevel gear-4 is meshed with can be wound around the vertical shaft Rotating bevel gear 2 12, said bevel gear 2 12 is fixedly sleeved with a screw 9, the lower end of the screw 9 extends into the valve body 7 and is threadedly connected with a transmission member 6, and the transmission member 6 is fixed to the valve plate 10 Connected, the upper end of the screw rod 9 extends out of the bevel gear 2 12 and is provided with a coupling 13, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com