A Crack Recognition Technology of Nodular Cast Iron Fracture Toughness JIC Specimen

A technology for ductile iron and fracture toughness, which is applied in the field of identification technology of ductile iron fracture toughness JIC specimen cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A process for identifying cracks in ductile iron fracture toughness JIC samples, the specific preparation steps are as follows:

[0021] Step 1. Select the nodular cast iron sample after the fracture toughness test and place it in a resistance heating furnace, start to heat up, and finally obtain the best process conditions for heat treatment through orthogonal experiments during the heat treatment process: the heating temperature is 340-360 ° C, The heating rate is 8-12°C, and the holding time is 0.8-1.2h;

[0022] Step 2: Stop heating the ductile iron sample, cool it to room temperature at a cooling rate of 0.8-1°C / min, break the cooled ductile iron sample on a mechanical testing machine, and obtain a ductile iron fracture toughness fracture sample ;

[0023] Step 3. Place the ductile iron fracture toughness fracture sample under the tool microscope, and observe the colors of two different regions under the tool microscope. The color dividing line of the above two re...

Embodiment 2

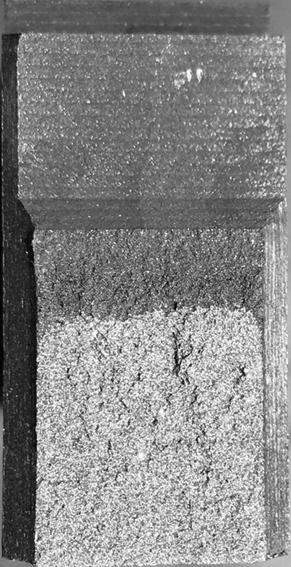

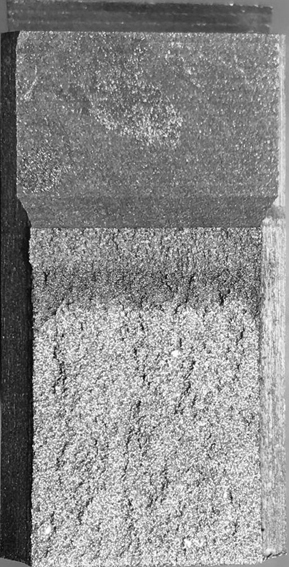

[0031] Two batches of nodular cast iron were selected for fracture toughness J IC After the test, adopt the crack recognition process provided by the invention to carry out heat treatment, and the sample fracture photo after heat treatment is as follows: figure 1 with figure 2 As shown, the two pieces of ductile iron made of different materials are obviously blue, dark brown, light brown, and dark brown respectively. The intersection of the two colors on the fracture of the same ductile iron sample above is the crack line, and the fracture crack is clearly visible. , the crack length can be obtained effectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com