Automatic lifting overhead lumbering device

A technology of automatic lifting and equipment, applied in cranes, forestry, applications, etc., can solve the problems of ground building impact damage, threatening the life safety of ground workers, unsolved trees falling smoothly, etc., to prevent impact damage and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be further described below, but it is not used to limit the scope of the present invention:

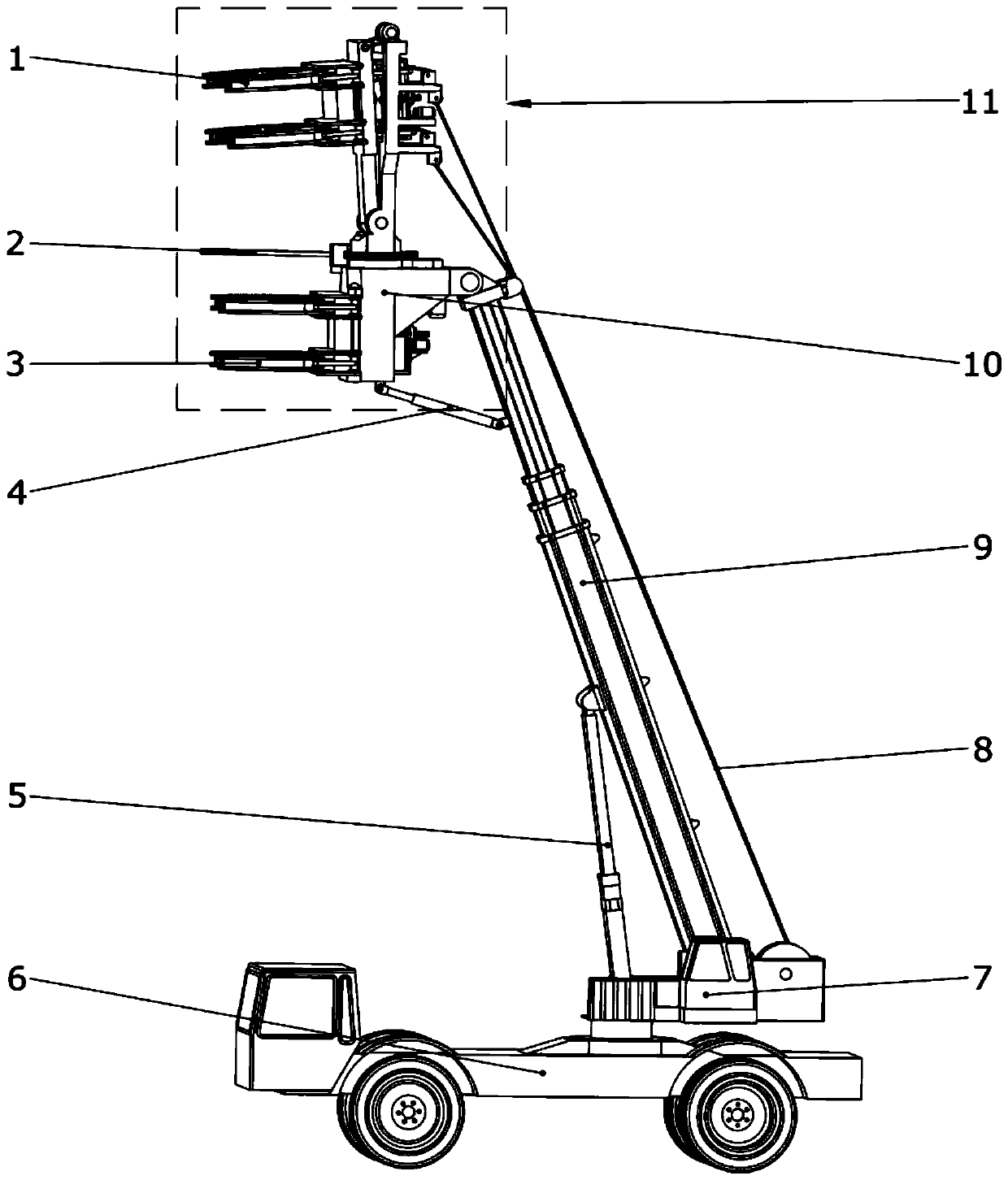

[0037] Such as figure 1Shown, a kind of automatic lifting type high-altitude logging equipment comprises car body 6, boom 9 and self-lowering device 11 three parts. The car body 6 is used to transport the felling equipment to realize the flexible adjustment of the position and angle of the felling equipment; the boom 9 is used to adjust the self-lowering device 11 to the required felling position and height. During the felling operation, the self-lowering device 11 The claws on the top will hold the trunk tightly, and the ground, the trunk, and the telescopic hydraulic arm 9 form a triangular structure, which enhances the stability of the felling equipment when it is working; The trunk of the tree was lowered smoothly and landed safely.

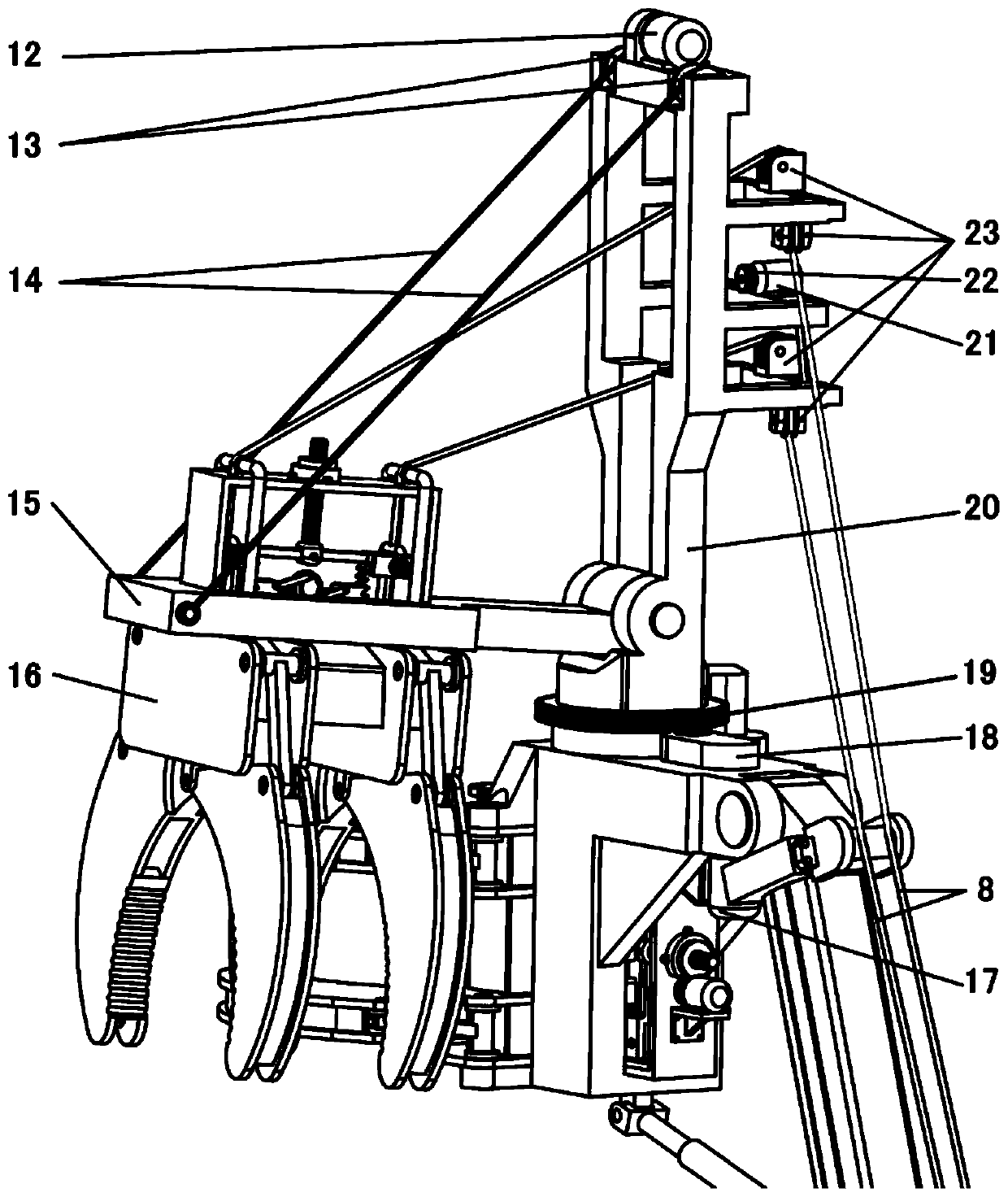

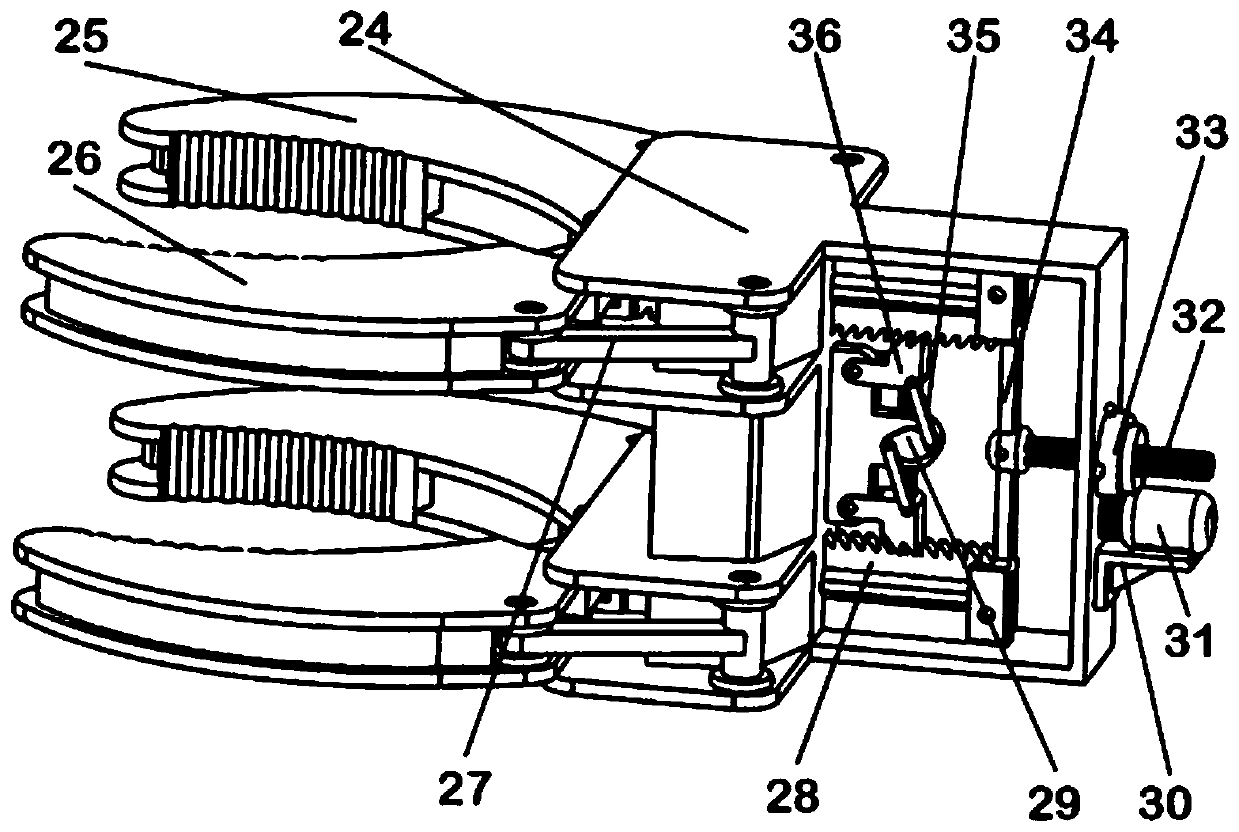

[0038] Such as figure 1 , Figure 11 As shown, the car body is provided with a boom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com