Manufacturing method for fishbone broken milkfish

A production method and technology for milkfish, which are applied in the direction of cutting fish into pieces, etc., can solve the problems of inability to improve the development of milkfish industry and the consumer market, limited output, and labor consumption, so as to improve the consumer market and improve the The effect of industrial development and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Relevant present invention is for reaching above-mentioned purpose of use and effect, the technical means that adopts, presents preferred feasible embodiment, and cooperates as shown in the accompanying drawings, is described in detail as follows:

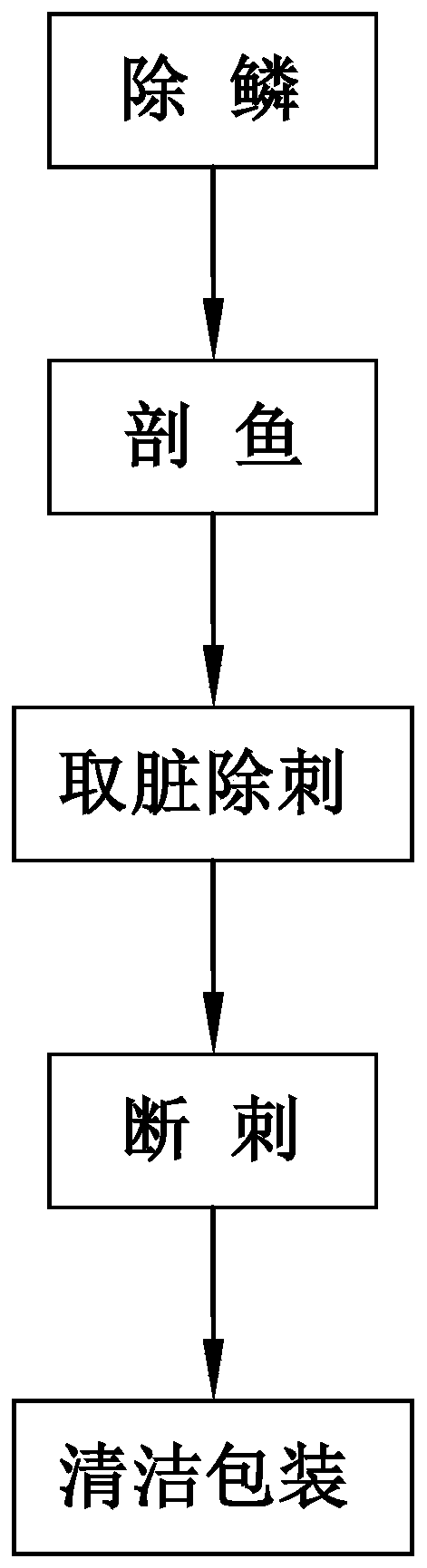

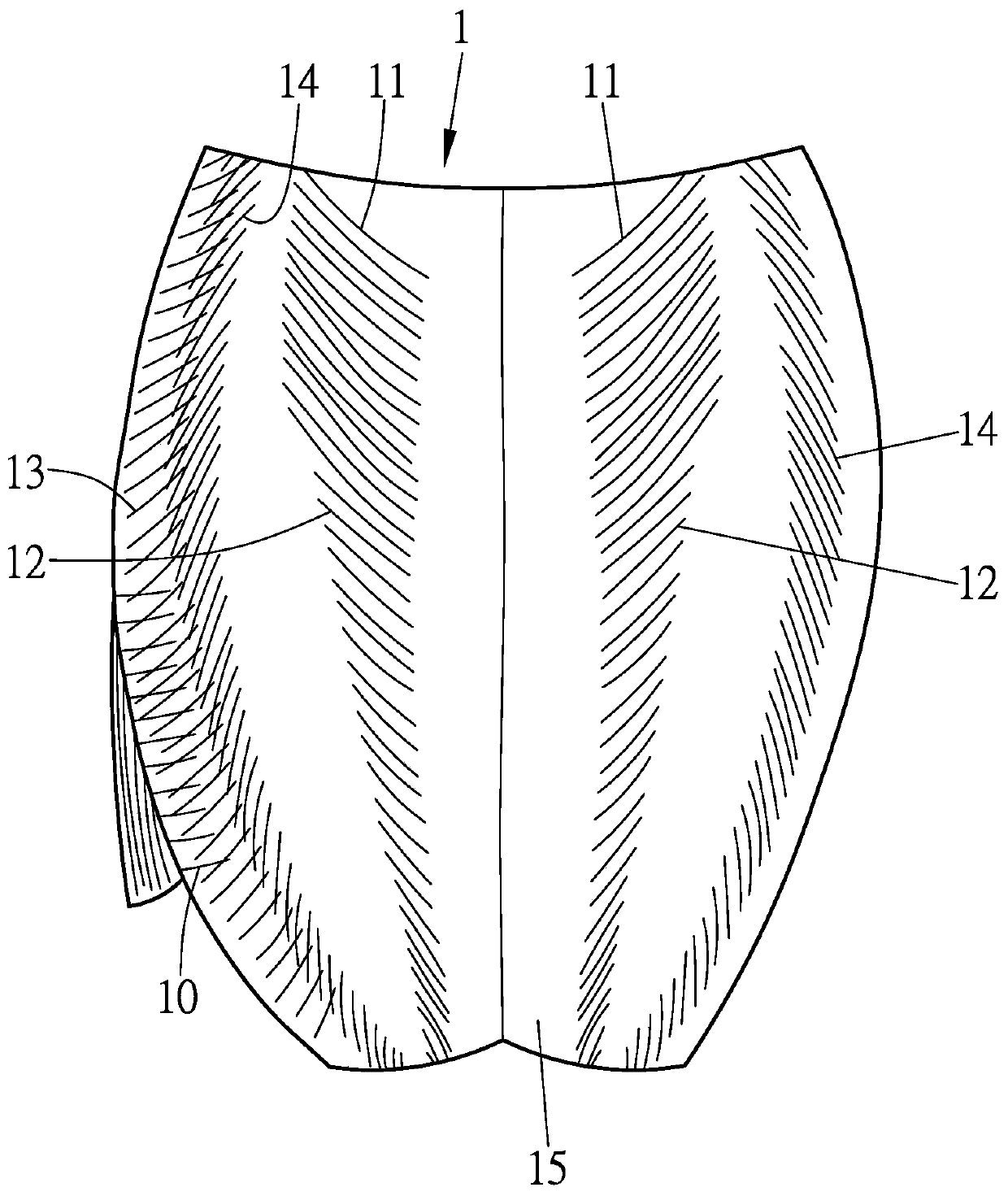

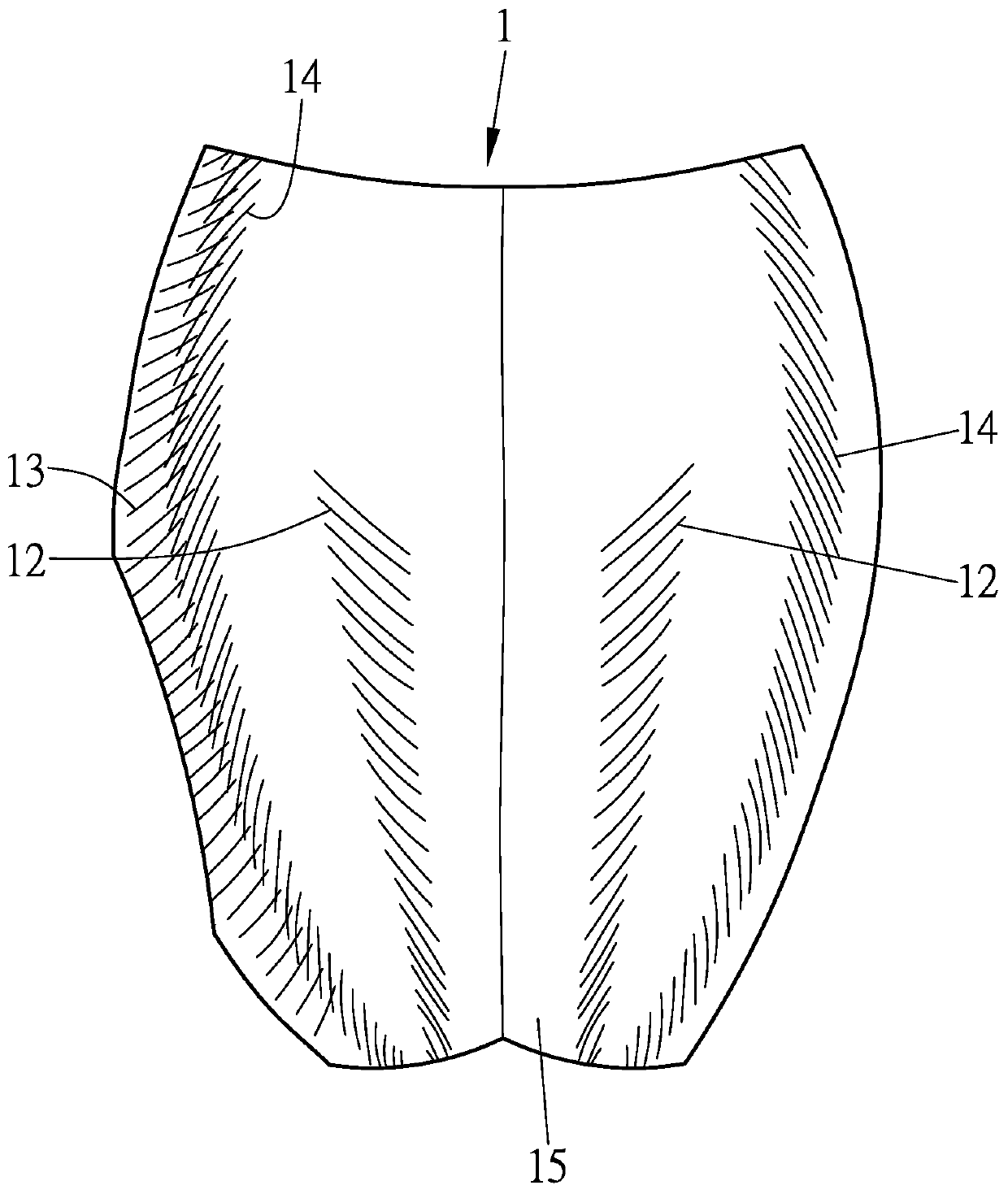

[0026] For an example of the invention, see figure 1 As shown, the main steps are: a. Descaling: scrape off the scales on the body of the milkfish; b. Cutting the fish: first cut off the head and tail of the milkfish, and then cut the milkfish into milkfish Fish fillet 1; c, taking viscera and removing thorns: first the viscera of milkfish is taken out, and then the vertebral spurs, fin spines 10 and front maw spines 11 of milkfish are removed (such as figure 2 , 3 shown); d, broken thorns: horizontally finely cut the back maw thorns 12, back thorns 13, side back thorns 14 and fish meat 15 of milkfish (such as Figure 4 , 5 As shown), the length of the horizontally finely cut thorns is 1 to 4 mm (millimeters), and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com