Device for cleaning dialysate liquid storage barrels

A cleaning device and liquid storage tank technology, applied in the field of medical machinery, can solve the problems of high impact force of pure water and inability to ensure the cleaning of the inside of the tank, and achieve the effects of easy removal, strong cleaning effect, and simple and convenient equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

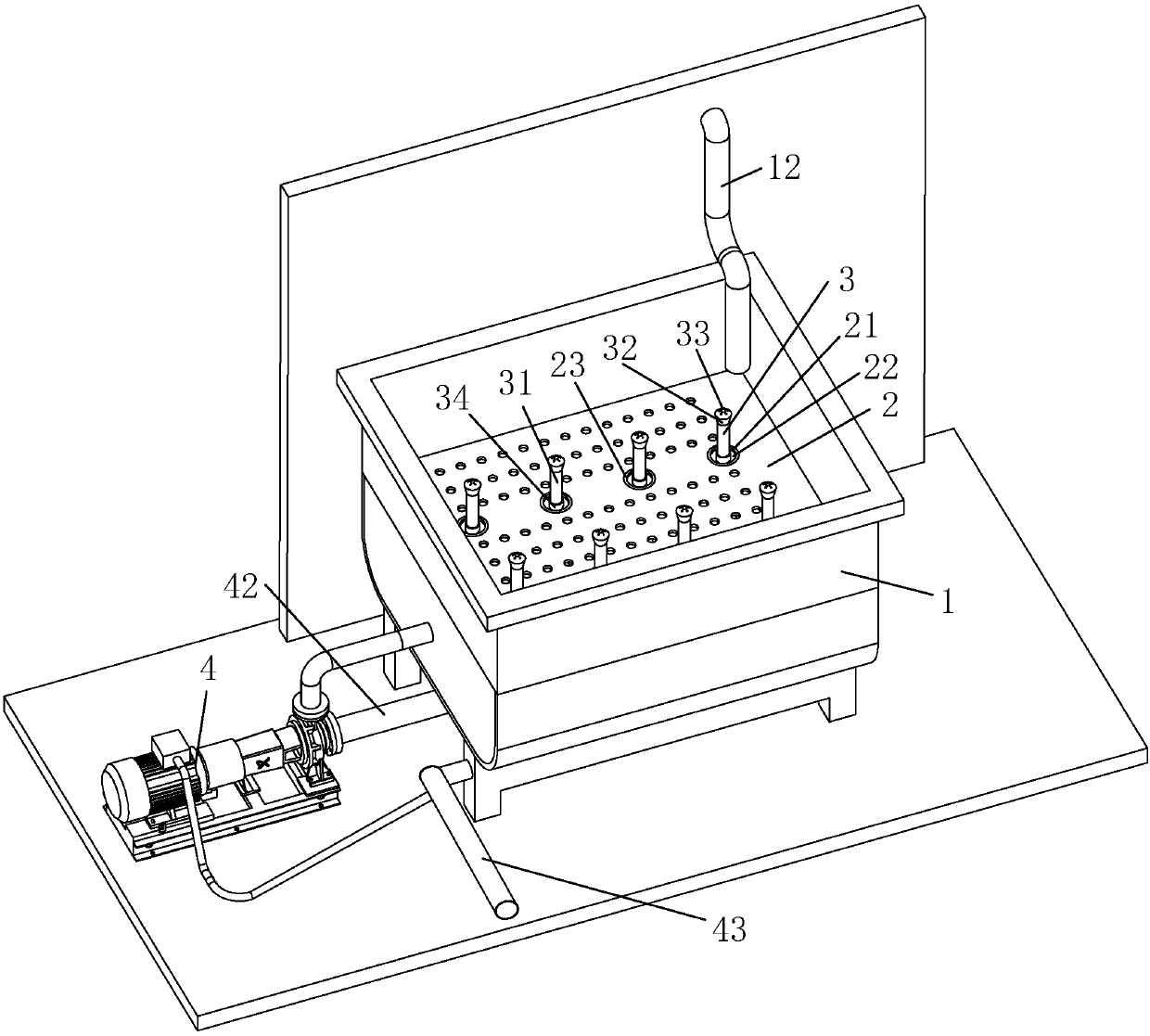

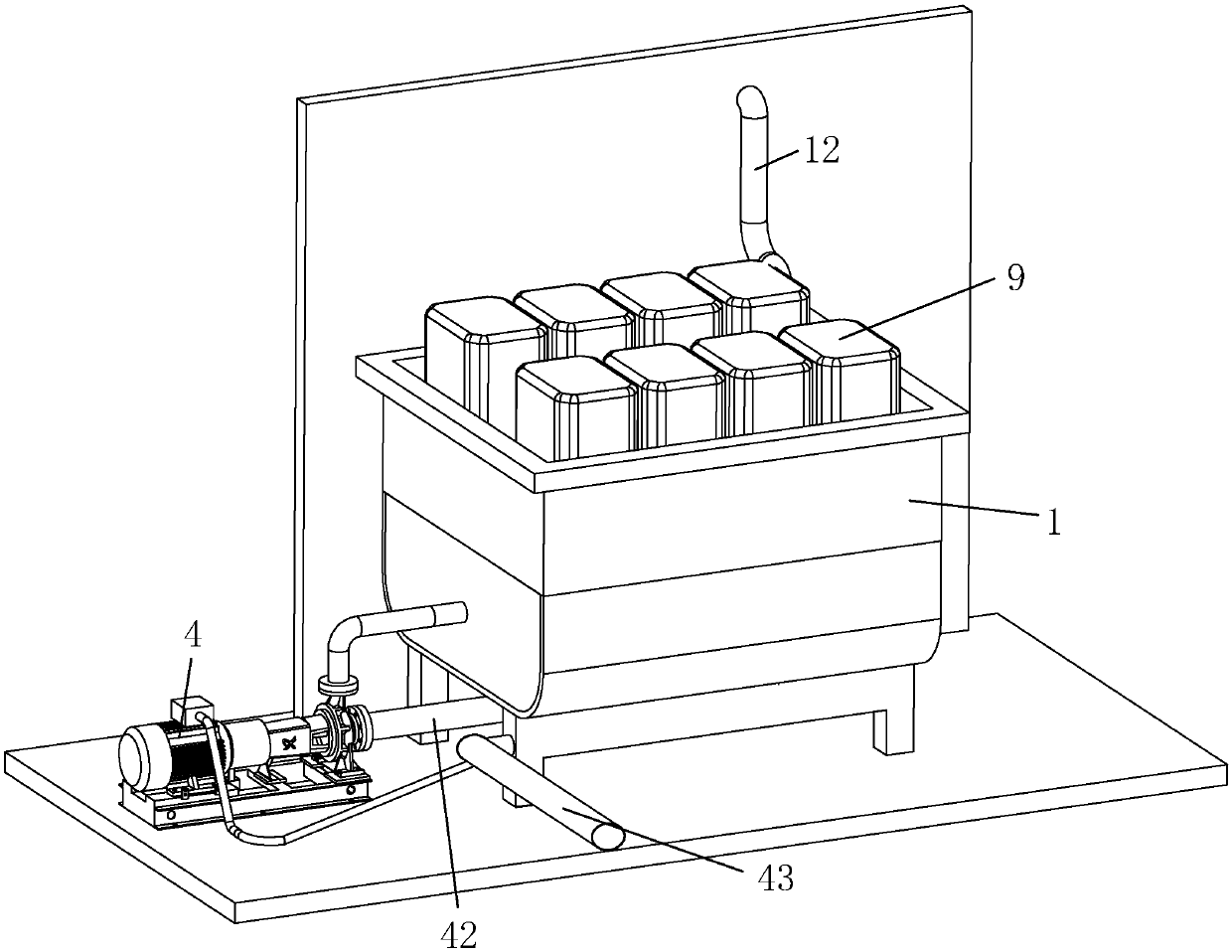

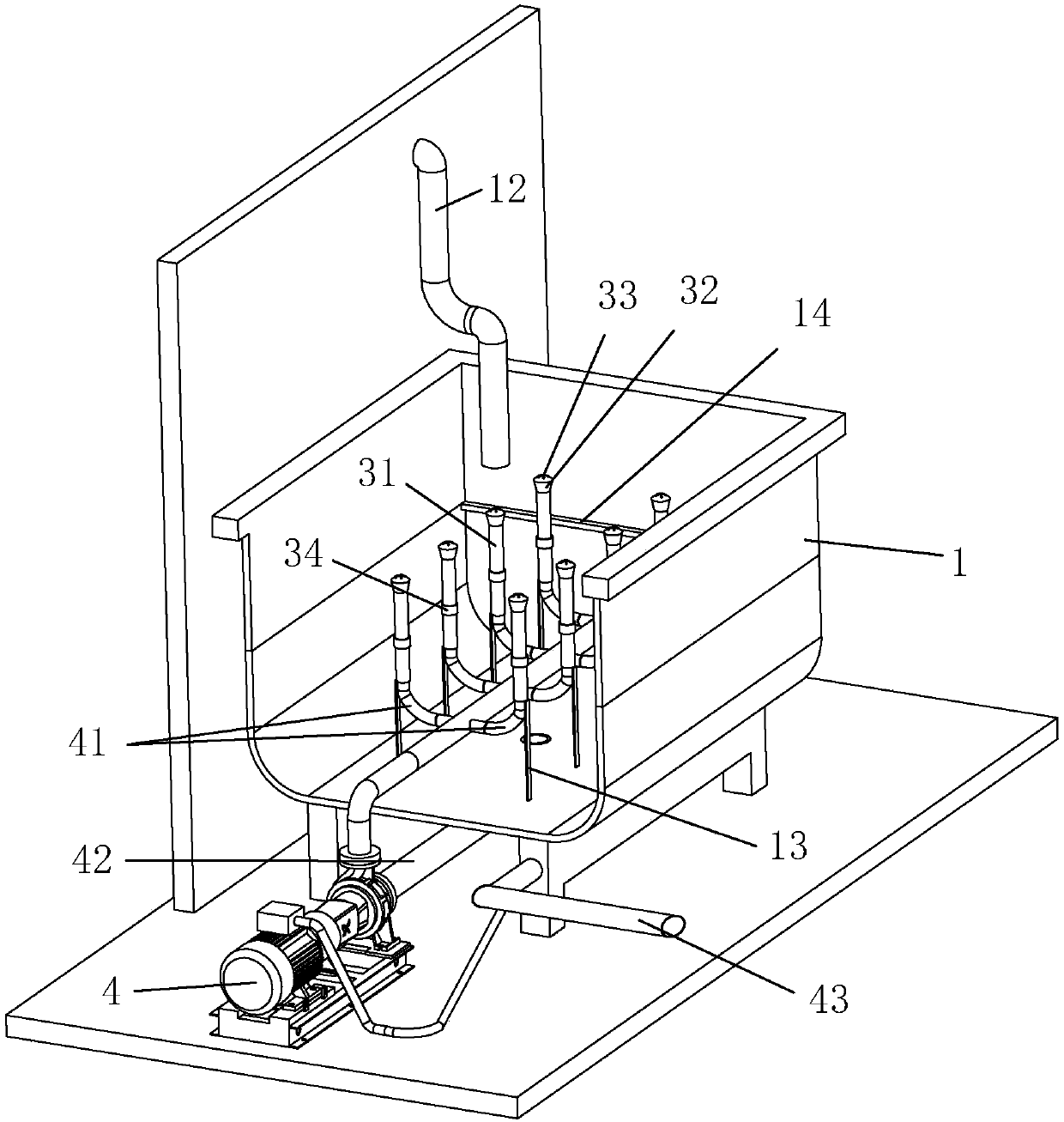

[0033] A dialysate storage tank cleaning device, such as figure 1 , 2 As shown, it includes a cleaning box 1, a water leakage baffle 2, a cleaning nozzle 3, and a water pump 4 for supplying water to the cleaning nozzle 3. The bottom of the cleaning box 1 is provided with a drain valve 11, and the cleaning nozzle 3 is vertically fixed at the bottom of the cleaning box 1. , the inner edge of the cleaning box 1 is provided with a supporting rib 14, and the edge of the leaking baffle 2 is in contact with the supporting rib 14, and the leaking baffle 2 is provided with a fixing hole 21 protruding for the cleaning nozzle 3, and the fixing hole 21 and the cleaning There is a gap 22 between the nozzles 3 for inserting the barrel tube 91 of the drug liquid storage barrel 9. People align the barrel tube 91 of the drug liquid storage barrel 9 with the cleaning nozzle 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com