Nut quick-disassembling tool suitable for small-spacing construction space

A technology of construction space and dismantling tools, applied in the field of nut quick dismantling tools, can solve problems such as difficulty in pre-tightening and dismantling of large nuts, and achieve the effect of avoiding personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

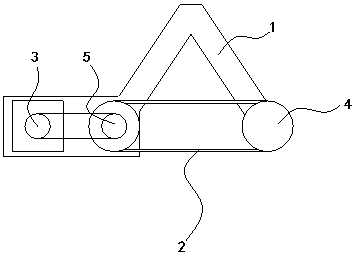

[0026] Embodiment 1: A quick disassembly tool for nuts suitable for small-pitch construction spaces, refer to figure 1 As shown, it includes a frame 1, a belt 2, a motor 3, a support wheel 4 and a transmission wheel 5, the support wheel 4 and the transmission wheel 5 are rotatably installed at both ends of the frame 1, and the motor 3 is connected to the transmission wheel 5 , the belt 2 is loosely installed on the supporting wheel 4 and the driving wheel 5, the belt 2 is stretched by the supporting wheel 4 and the driving wheel 5, and a rectangular space for inserting a nut is formed in the middle. When in use, the belt 2 may not be completely fitted on the support wheel 4 because it is in a loose state. After putting the belt 2 on the nut, it needs to be pulled outward to make the belt 2 tight and fully in contact with the nut, and then adjust the belt 2. , the motor 3 is used to drive the belt 2, and the nut is rotated by the friction force between the belt 2 and the nut to...

Embodiment 2

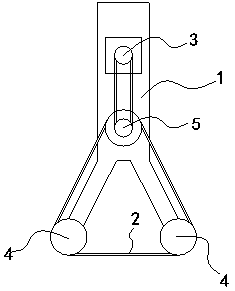

[0029] Embodiment 2: A quick disassembly tool for nuts suitable for small-pitch construction spaces, refer to figure 2 As shown, it includes a frame 1, a motor 3, a belt 2, a transmission wheel 5, and two support wheels 4. The two support wheels 4 are rotatably mounted on the frame 1, and the transmission wheel 5 is rotatably mounted. On the frame 1, the motor 3 is in drive connection with the drive wheel 5, the belt 2 is sleeved on the two support wheels 4 and the drive wheel 5 in a loose state, and the belt 2 is covered by the two support wheels 4 and the drive wheel 5 spread out to form a triangular space in the middle for inserting nuts. When in use, the belt 2 may not be completely set on the supporting wheel 4 and the transmission wheel 5 because it is in a loose state. After the belt 2 is placed on the nut, it needs to be pulled outward to make the belt 2 tight and fully contact with the nut. Adjust the belt 2, use the motor 3 to drive the belt 2, and make the nut rot...

Embodiment 3

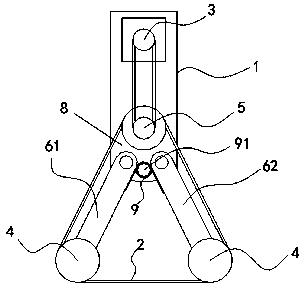

[0034] Embodiment 3: A quick disassembly tool for nuts suitable for small-pitch construction spaces, refer to image 3 , comprising a frame 1, a motor 3, a torsion spring 9, a belt 2, a drive wheel 5 and two support wheels 4, the frame 1 comprises a base 8, a first support arm 61, a second support arm 62, a base 8, The first support arm 61 and the second support arm 62 form a Y-shaped structure, the transmission wheel 5 is rotatably mounted on the base 8, the motor 3 is mounted on the base 8, and the motor 3 is connected to the transmission wheel 5 , the belt 2 is sleeved on the transmission wheel 5 and the two support wheels 4 to form a triangular space, one end of the first support arm 61 is provided with a cylindrical shaft for rotatably mounting the support wheels 4, and the other end is rotatably connected On the base 8, one end of the second support arm 62 is provided with a cylindrical shaft for rotatably mounting the support wheel 4, and the other end is rotatably conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com