Air inlet protective plug for train brake rear cover and preparation method thereof

A technology of air inlet and protective blocking, applied in the direction of railway braking system, etc., can solve the problems of affecting the service life of accessories, affecting the normal operation of equipment, and paint falling off the air inlet joint, so as to reduce fiber loss, improve chemical stability, The effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

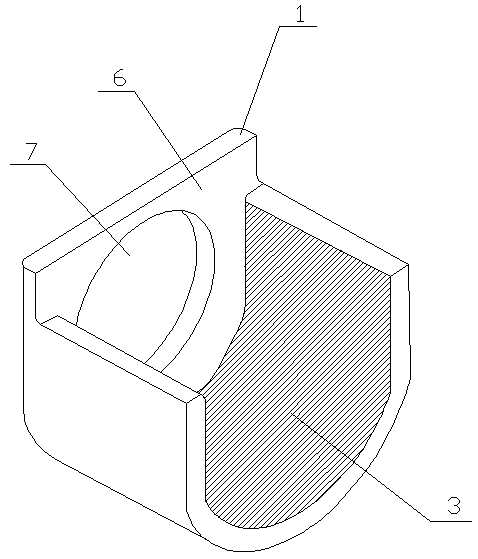

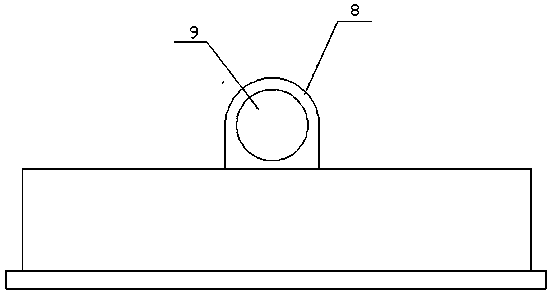

[0034] This embodiment provides a protective plug for the air inlet 9 of the rear cover of the train brake, which includes a protective sleeve 1 and a threaded plug 2 for the air inlet 9 . see figure 1 The protective cover 1 includes an arc-shaped plate whose radian is the same as that of the joint 8 of the air inlet 9, so that a slot 3 matching the shape of the joint 8 of the air inlet 9 is formed in the protective cover 1. A limit baffle 6 is arranged on the front side of the arc-shaped plate, and a through hole 7 is opened in the middle part of the limit baffle 6 corresponding to the position of the air inlet 9 , and the diameter of the through hole 7 is equal to the diameter of the air inlet 9 .

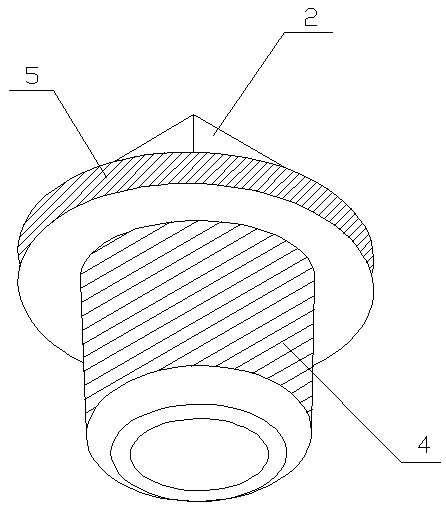

[0035] Air inlet 9 threaded plug 2 comprises threaded rod 4 and the plugging 5 that is arranged on the end of threaded rod 4, see figure 2 , the surface of the threaded rod 4 is provided with an external thread that matches the internal thread of the air inlet 9. When installi...

Embodiment 2

[0047] This embodiment provides a protective plug for the air inlet 9 of the rear cover of the train brake, which includes a protective sleeve 1 and a threaded plug 2 for the air inlet 9 . see figure 1 The protective cover 1 includes an arc-shaped plate whose radian is the same as that of the joint 8 of the air inlet 9, so that a slot 3 matching the shape of the joint 8 of the air inlet 9 is formed in the protective cover 1. A limit baffle 6 is arranged on the front side of the arc-shaped plate, and a through hole 7 is opened in the middle part of the limit baffle 6 corresponding to the position of the air inlet 9 , and the diameter of the through hole 7 is equal to the diameter of the air inlet 9 .

[0048] Air inlet 9 threaded plug 2 comprises threaded rod 4 and the plugging 5 that is arranged on the end of threaded rod 4, see figure 2 , the surface of the threaded rod 4 is provided with an external thread that matches the internal thread of the air inlet 9. When installi...

Embodiment 3

[0060] This embodiment provides a protective plug for the air inlet 9 of the rear cover of the train brake, which includes a protective sleeve 1 and a threaded plug 2 for the air inlet 9 . see figure 1 The protective cover 1 includes an arc-shaped plate whose radian is the same as that of the joint 8 of the air inlet 9, so that a slot 3 matching the shape of the joint 8 of the air inlet 9 is formed in the protective cover 1. A limit baffle 6 is arranged on the front side of the arc-shaped plate, and a through hole 7 is opened in the middle part of the limit baffle 6 corresponding to the position of the air inlet 9 , and the diameter of the through hole 7 is equal to the diameter of the air inlet 9 .

[0061] Air inlet 9 threaded plug 2 comprises threaded rod 4 and the plugging 5 that is arranged on the end of threaded rod 4, see figure 2 , the surface of the threaded rod 4 is provided with an external thread that matches the internal thread of the air inlet 9. When installi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com