Winding device used for flexible LED filament production

A technology of LED filament and winding device, which is applied in lighting devices, transportation and packaging, and conveying filamentous materials, etc. It can solve the problems of uneven winding and dust cleaning on the surface of the filament, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

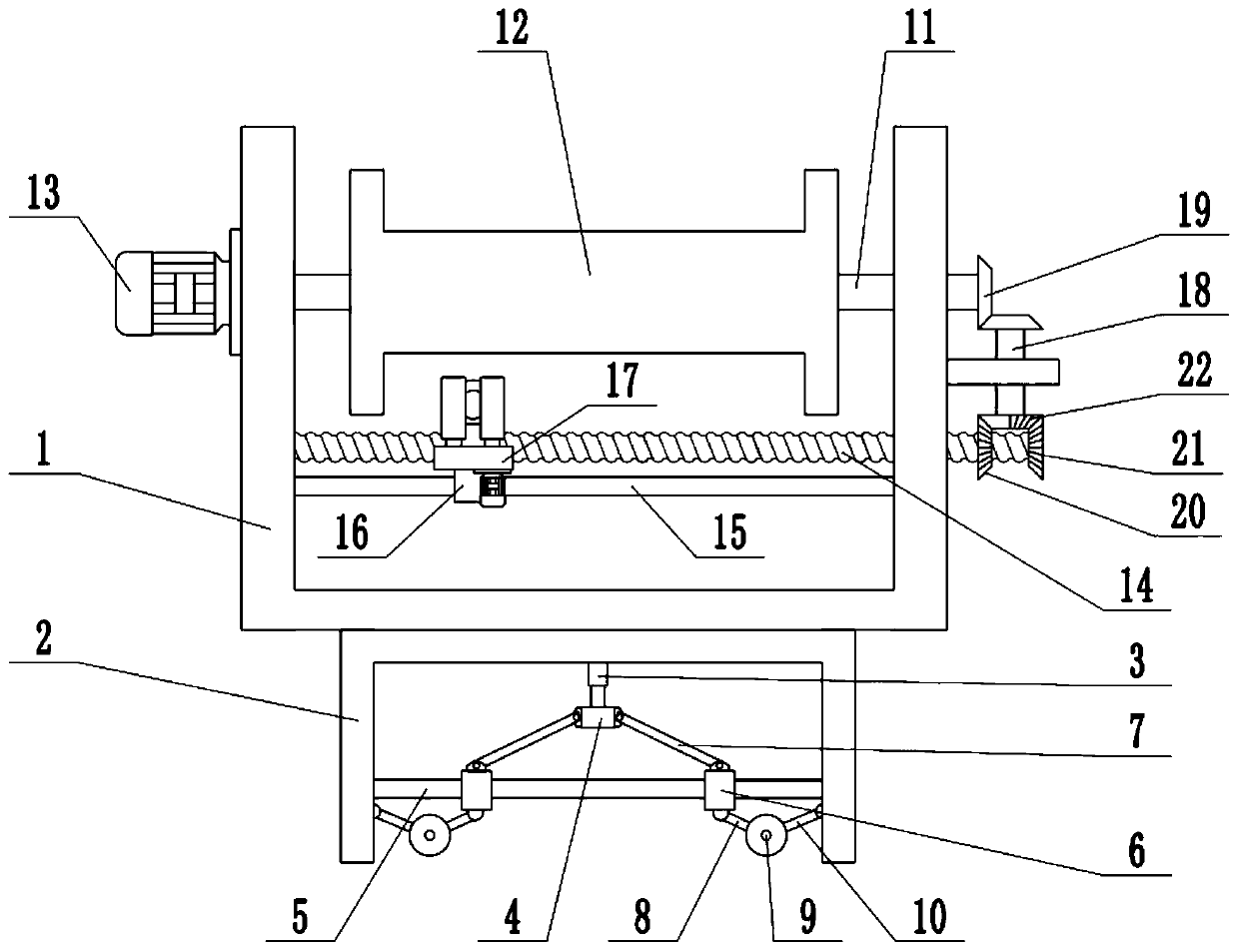

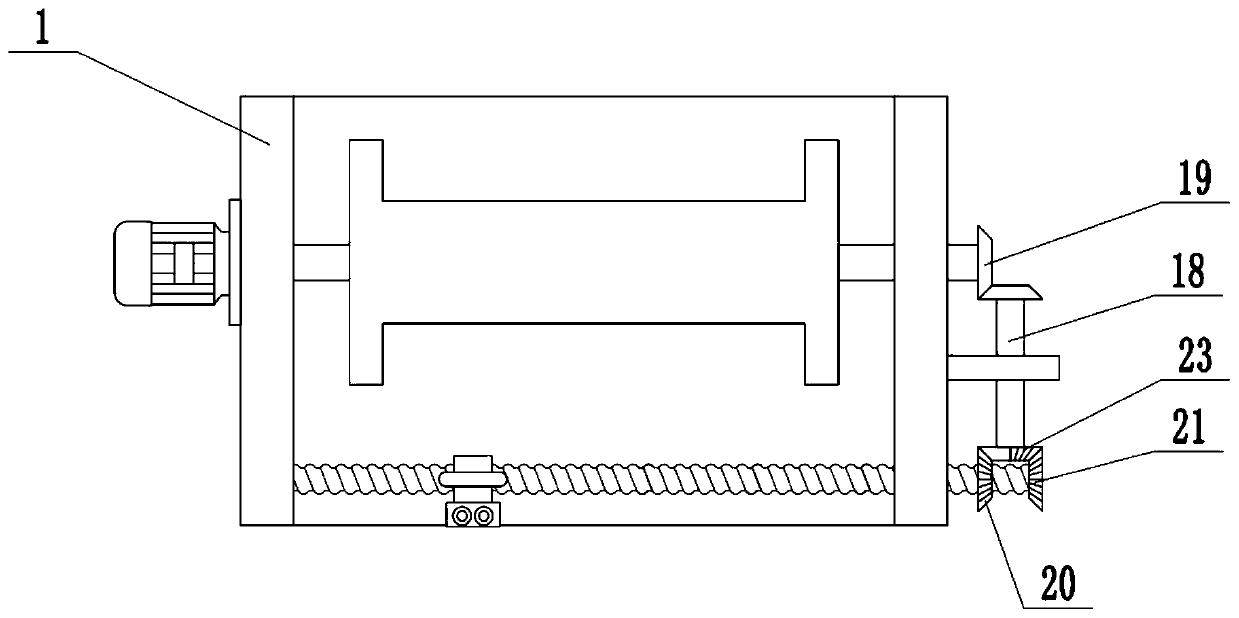

[0021] see Figure 1-4 , in an embodiment of the present invention, a winding device for the production of flexible LED filaments, including a fixed frame 1, a winding roller 12 and a winding motor 13, a support frame 2 is installed on the lower surface of the fixed frame 1, and the fixed frame 1 The drive shaft 11 is installed inside, and the left and right ends of the drive shaft 11 are respectively connected to the side wall of the fixed frame 1. The middle part of the drive shaft 11 is provided with a winding roller 12 for winding the flexible LED filament. The fixed frame 1 The outer wall of the outer wall is fixedly connected with a winding motor 13, and the shaft extension end of the winding motor 13 is connected with the winding roller 12, and the inside of the fixed frame 1 is also equipped with a screw mandrel 14, and the left and right ends of the screw mandrel 14 are connected with the fixed frame respectively. The side wall of 1 is rotationally connected, and the ...

Embodiment 2

[0023] On the basis of Embodiment 1, a moving mechanism is installed inside the support frame 2, and the moving mechanism includes a telescopic mechanism 3, a lifting block 4, a sliding rod 5, a movable block 6, a first connecting rod 7, a second connecting rod 8, a rolling Axis 9 and the third connecting rod 10, telescopic mechanism 3 are fixedly connected on the top of support frame 2, telescopic mechanism 3 is an electrohydraulic telescopic cylinder, and the lower end of telescopic mechanism 3 is fixedly connected with lifting block 4, and the left and right sides of lifting block 4 are all A first connecting rod 7 is hinged, and the lower end of the first connecting rod 7 is hinged with a movable block 6. A sliding rod 5 is arranged below the lifting block 4, and the left and right ends of the sliding rod 5 are fixedly connected with the side walls of the support frame 2 respectively. Slide bar 5 runs through movable block 6, and movable block 6 is slidingly connected with ...

Embodiment 1、 Embodiment 2

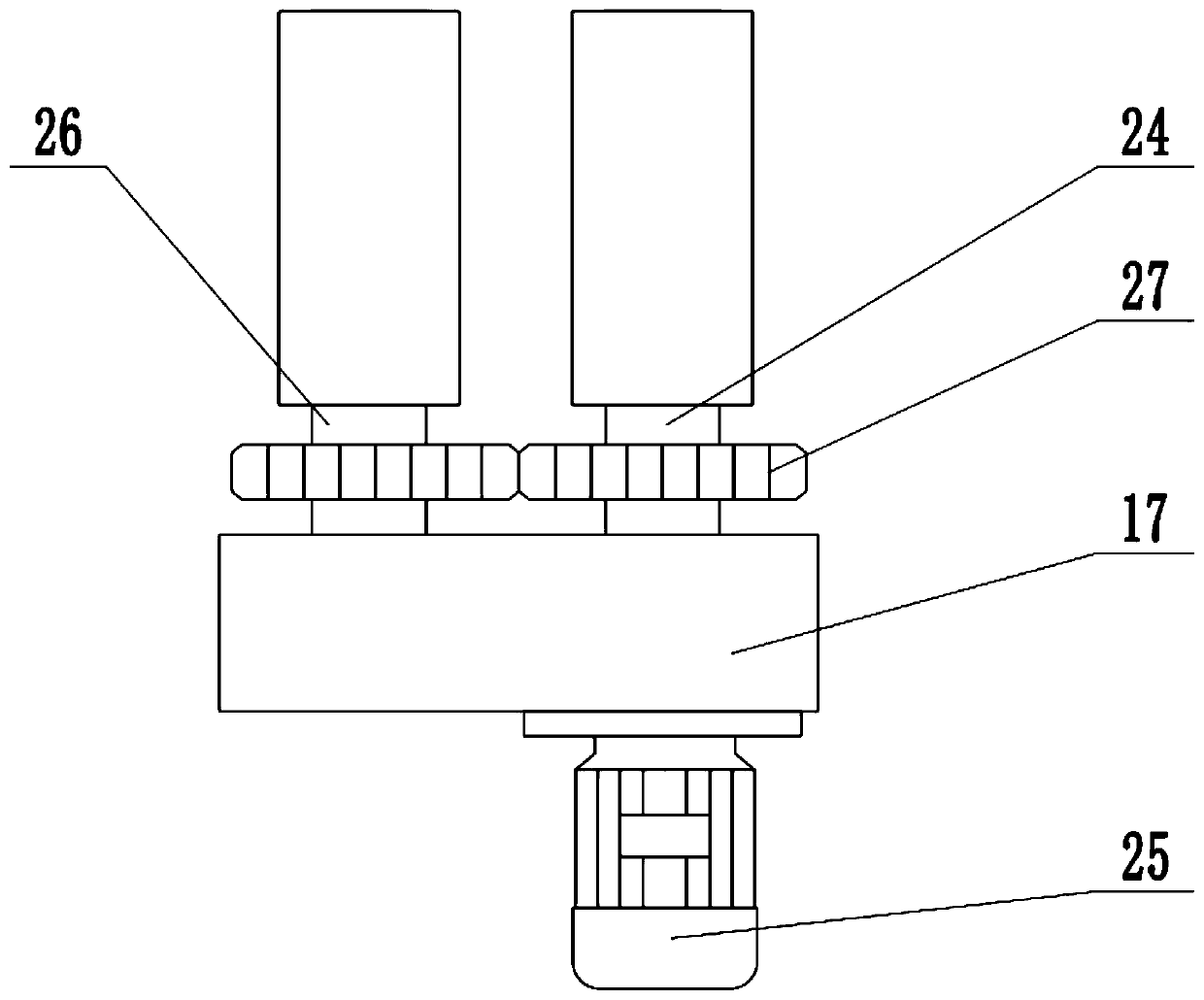

[0024] Combining Embodiment 1 and Embodiment 2, the working principle of the present invention is: the flexible LED filament to be wound passes between the active cleaning roller 24 and the driven cleaning roller 25, and is wound on the winding roller 12 through the guide ring 23 On, start the winding motor 13, drive the winding roller 12 to rotate, make the filament wind on the winding roller 12, when the driving shaft 11 rotates, drive the transmission shaft 18 to rotate through the bevel gear set 19, when the half bevel gear 22 and the left bevel When the gear 20 meshes, it drives the screw mandrel 14 to rotate. When the half bevel gear 22 separates from the left bevel gear 20 and meshes with the right bevel gear 21, it drives the screw mandrel 14 to reverse, and so on, so that the screw mandrel 14 is driven to rotate forward and backward, thereby Drive the slider 16 to move left and right, so that the filament is evenly wound on the winding roller 12, and at the same time s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com