Unitized logistics operation system and method

An operating system and logistics technology, applied in the direction of lifting devices, etc., can solve the problems of influence, height increase, and poor operation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

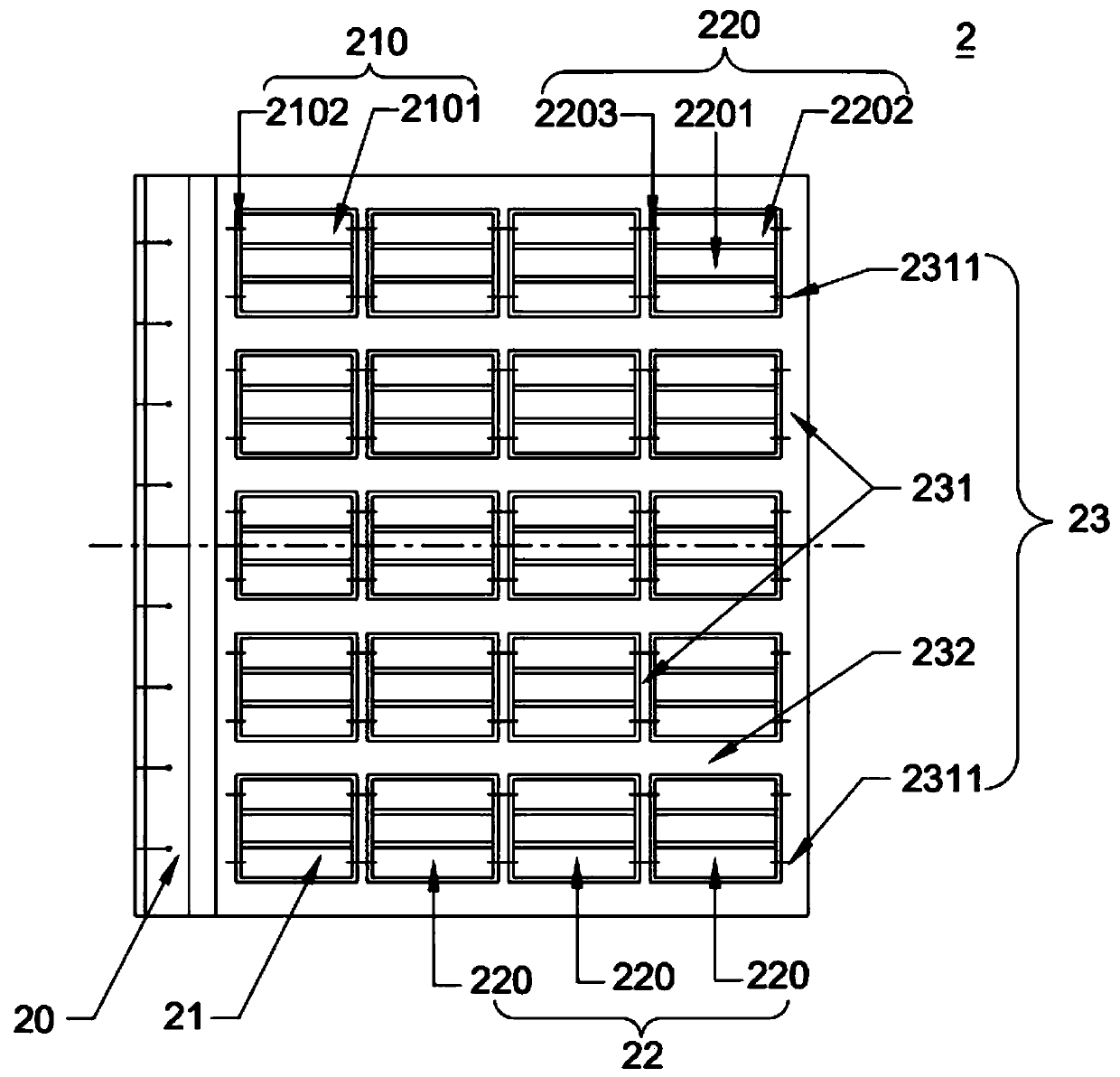

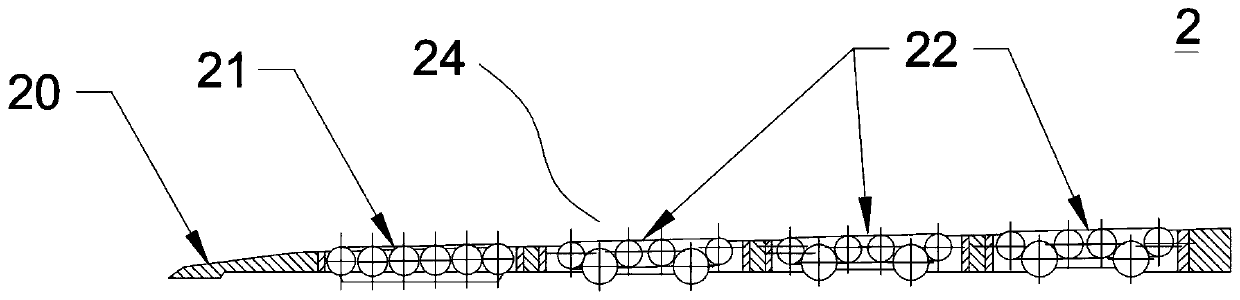

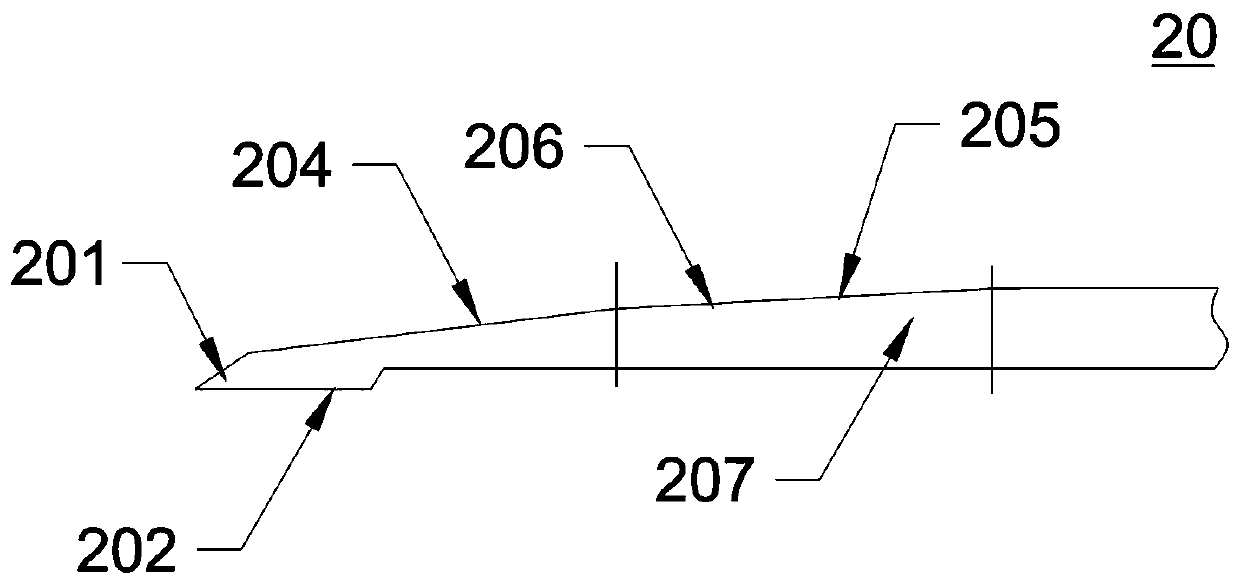

[0084] Such as Figure 1-Figure 15 As shown, the cargo transposition device 2 includes a wear-reducing front tongue 20 , a gravity type traveling roller table 21 , a gravity type walking aid roller table 22 , a grid base plate 23 , an upper working surface 24 and a leveling mechanism 25 . Specifically, such as figure 1 with figure 2 As shown, the longitudinal section of the cargo transposition device 2 is wedge-shaped, and includes three functional sections from the start of operation: the front wear-reducing front tongue 20, the gravity-type accompanying roller table 21 in the middle section, and the gravity-type walking aid in the middle and rear sections. Roller table 22. The grid base plate 23 combines the three functional sections to form the upper working surface 24 after the combination. The push-flat mechanism 25 is longitudinally arranged at the bottom of the gravity-type walking roller table 21 and the gravity-type walking-aid roller table 22. Each of the above ...

Embodiment 2

[0111] Such as Figure 16 with Figure 17 As shown, the cargo transposition fork 5 includes the cargo transposition device 2 without the flattening mechanism 25 in Embodiment 1 and the reinforcing ribs 52 on both sides, the fork connecting arm 50 at the rear, the fork connecting pin 501, Fork tool roller 502, fork tool vertical arm 51, vertical arm positioning hook 511.

[0112] The horizontal arm of the fork connecting arm 50 is connected with the cargo transposition device 2, the vertical arm of the fork connecting arm 50 is connected with the vertical arm 51 of the fork, and the vertical arm 51 of the fork is connected and positioned with the mast of the forklift through the vertical arm positioning hook 511 .

[0113] When the cargo transposition fork tool 5 is installed and used on a forklift, in other embodiments of the present invention, under the operation system of "packaging the front bottom corner corner protection strip" and setting the "vertical cargo rear wall"...

Embodiment 3

[0115] A unitized logistics operation method that utilizes use The cargo transposition fork in embodiment 2 is installed and used on a forklift, and the unit goods without pallets are carried out to carry out the handling and storage of the unit goods in the warehouse plane position, the unitized logistics operation method of storage, and the unitized logistics operation method of loading And the unit logistics operation method of unloading.

[0116] The unitized logistics operation method of carrying out the unit goods without pallet operation for the handling and storage of the warehouse plane cargo location includes the following steps:

[0117] S1. Packing operation of front-facing bottom corner corner protectors: For unit goods that need to be processed without pallets, in addition to packaging in the horizontal direction, the front-facing bottom corner corner protectors of the goods must also be packed. The corner protectors have outer rounded corners and Warning signs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com