Split main speed reducer

A main reducer, split technology, applied in the direction of electric power device, control device, power device, etc., can solve the problems of large space occupation, affecting the use of vehicle space, etc., to avoid space occupation, improve the actual load rate, and ensure the transmission efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

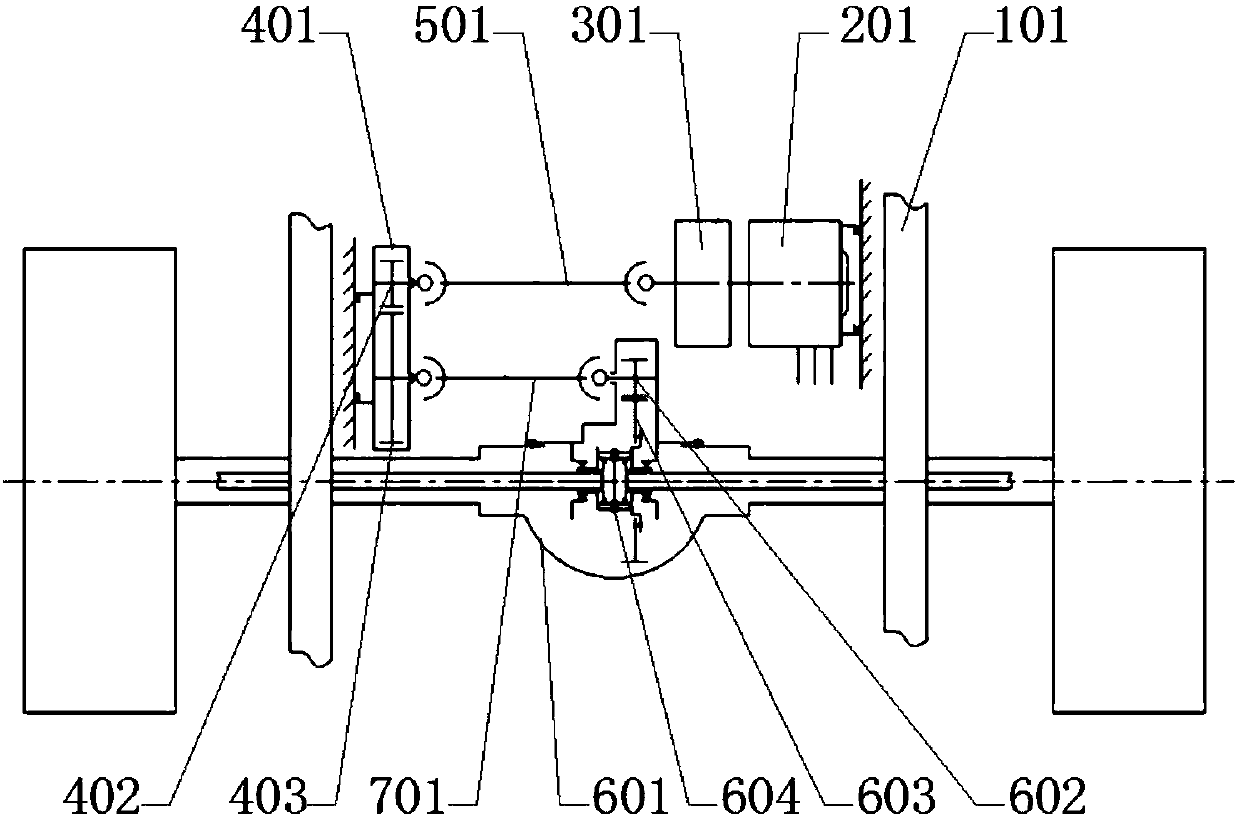

[0025] see figure 1 , this embodiment discloses a split-type main reducer, the power unit 201 and the transmission 301 are connected to one side of the vehicle body 101 (in this embodiment, the power unit transmits power to the first transmission shaft after being shifted by the transmission) . The power unit 201 is in transmission connection with the power input end of the transmission 301 , and the first speed reducer 401 is connected to the other side of the vehicle body 101 and includes a first transmission gear 402 and a second transmission gear 403 . The first transmission gear 402 is in transmission connection with the power output shaft of the transmission 301 through the first transmission shaft 501 , and the second transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com