A high-temperature slag multiphase jet compound granulation powder making method

A slag, high temperature technology, applied in the field of new high-temperature slag multiphase jet composite granulation and milling, can solve the problems of difficult processing, poor stability, low granulation and milling efficiency, and achieve the effect of concise and clear thinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

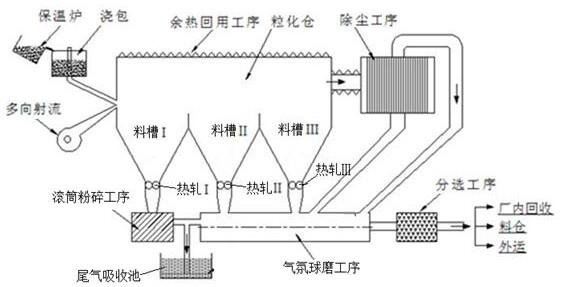

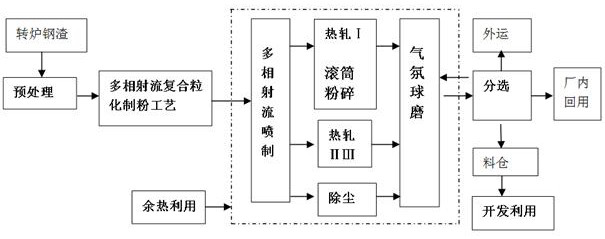

[0037] A multi-phase jet compound granulation milling method for converter steelmaking high-temperature slag, specifically comprising the following steps:

[0038] (1) Pretreatment of high-temperature slag from converter steelmaking: make the superheat △T of high-temperature slag from converter steelmaking 50°C~100°C, viscosity 0.04 Pa·s~0.3Pa·s; for SiO 2 .

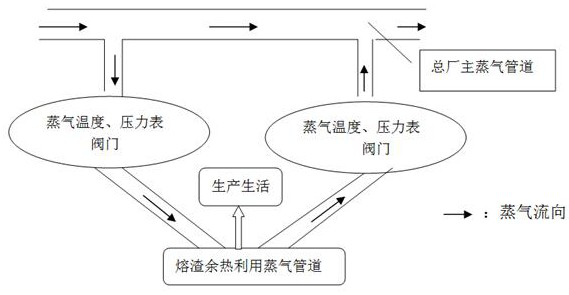

[0039] (2) The pretreated high-temperature slag is transported to the ladle, and the high-temperature slag is sprayed into the granulation bin by multi-phase jet spraying technology. The bottom of the granulation bin is equipped with multiple side-by-side troughs. After solidification Due to the different particle sizes, the high-temperature slag particles fall into different troughs. The slag particles coming out of the trough are hot-rolled and pulverized, and the slag particles in the trough near the side of the multi-phase jet spraying device are first heated. Rolling and crushing, and then roller crushing, the sla...

Embodiment 2

[0045] A multi-phase jet compound granulation powder-making method for high-temperature slag of copper smelting in an Isa furnace, specifically comprising the following steps:

[0046] (1) Pretreatment of the high-temperature slag of copper smelting in the Isa furnace: make the superheat △T of the slag 50°C~150°C, and the viscosity 0.05Pa·s~0.5Pa·s; the conditioner used for tempering is SiO 2 , Pulverized coal.

[0047] (2) The pretreated high-temperature slag is transported to the ladle, and the high-temperature slag is sprayed into the granulation bin by multi-phase jet spraying technology. The bottom of the granulation bin is equipped with multiple side-by-side troughs. After solidification Due to the different particle sizes, the high-temperature slag particles fall into different troughs. The slag particles coming out of the trough are hot-rolled and pulverized, and the slag particles in the trough near the side of the multi-phase jet spraying device are first heated. Ro...

Embodiment 3

[0053] A multi-phase jet compound granulation powder-making method for high-temperature slag of Osmelt furnace tin smelting, specifically comprising the following steps:

[0054] (1) Pretreatment of high-temperature slag from tin smelting in Osmelt furnace: make the superheat △T of slag 50°C~200°C, viscosity 0.04Pa·s~0.3Pa·s; conditioning agent used for tempering for SiO 2 .

[0055] (2) The pretreated high-temperature slag is transported to the ladle, and the high-temperature slag is sprayed into the granulation bin by multi-phase jet spraying technology. The bottom of the granulation bin is equipped with multiple side-by-side troughs. After solidification Due to the different particle sizes, the high-temperature slag particles fall into different troughs. The slag particles coming out of the trough are hot-rolled and pulverized, and the slag particles in the trough near the side of the multi-phase jet spraying device are first heated. Rolling and crushing, and then roller ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap