Weft insertion mechanism for preform knitting equipment

A technology of weft insertion mechanism and prefabricated body, which is applied in looms, textiles, textiles and papermaking, etc. It can solve the problems of poor product stability and excessive products, achieve good accuracy and precision, wide range of lifting height, and reduce labor the effect of participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

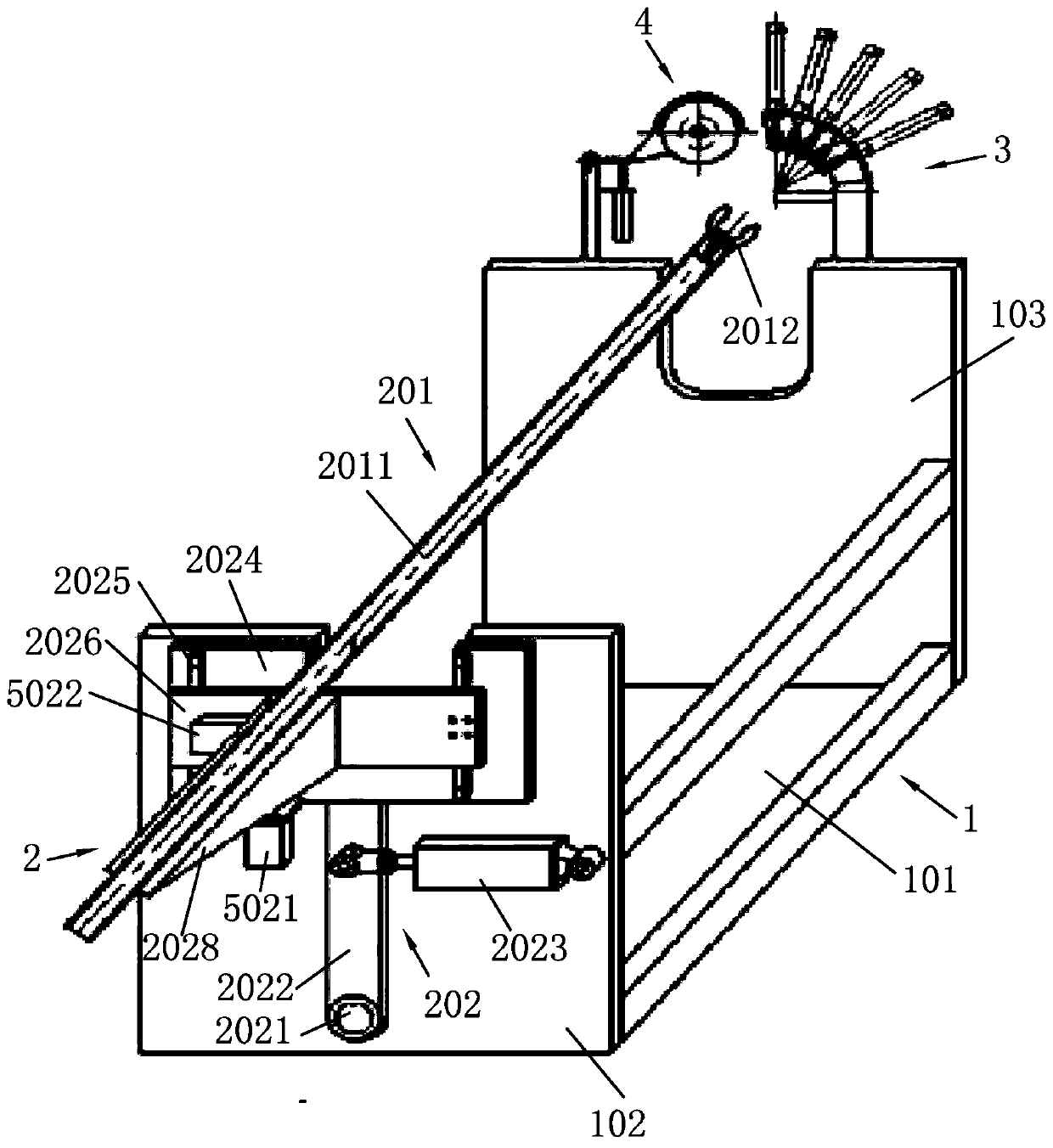

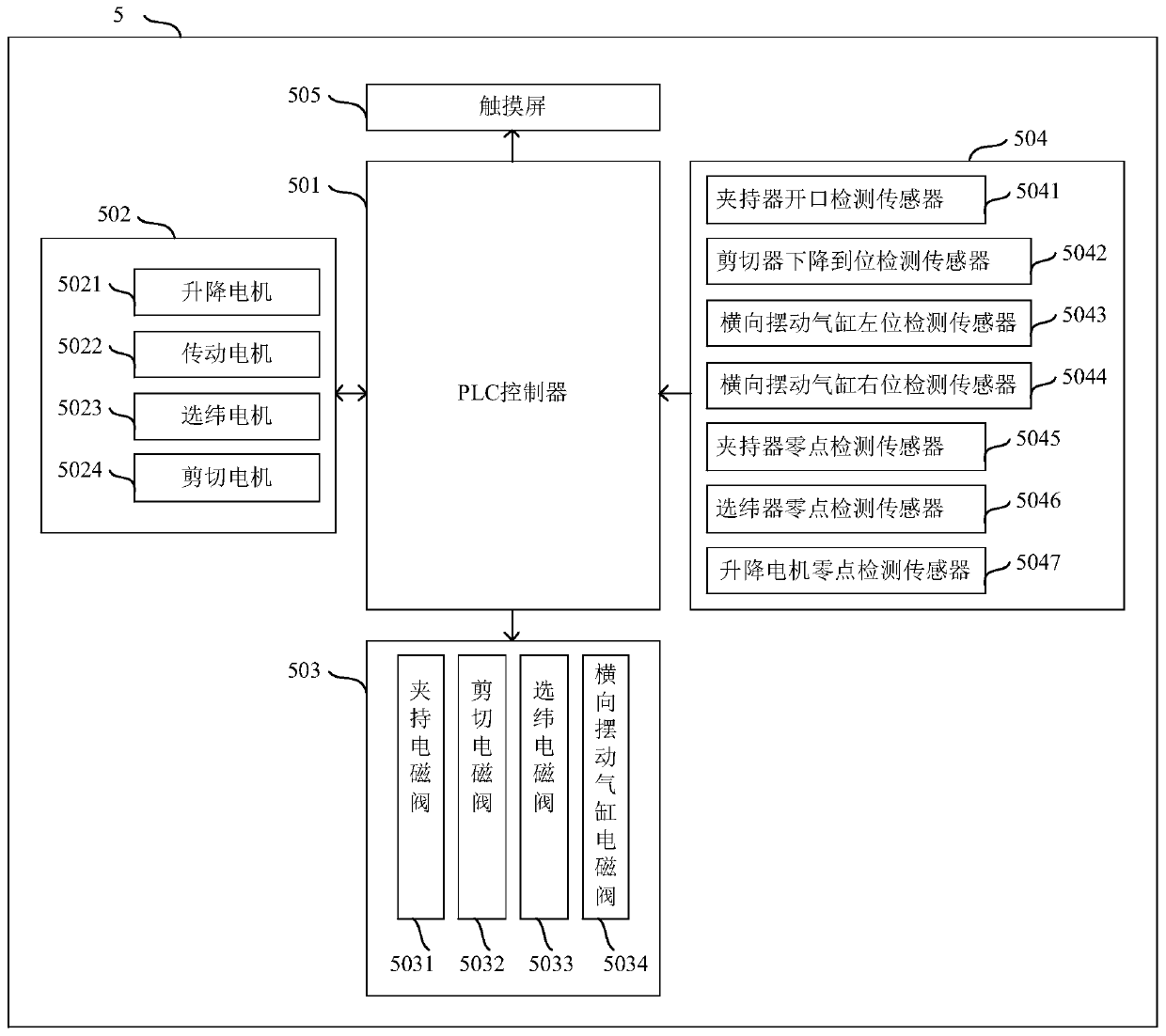

[0034] Please refer to Figure 1 to Figure 5 , the present invention is a weft insertion mechanism of preform weaving equipment, which includes a bracket 1, a clamping device 2, a weft selector 3, a cutter 4 and a control device 5; the clamping device 2, a weft selector 3 and a shear Cutter 4 is all located on the support 1.

[0035] refer to figure 1 , the bracket 1 includes a bottom plate 101 and two side plates that are respectively arranged on both sides of the bottom plate 101 and extend upwards; side panels 103;

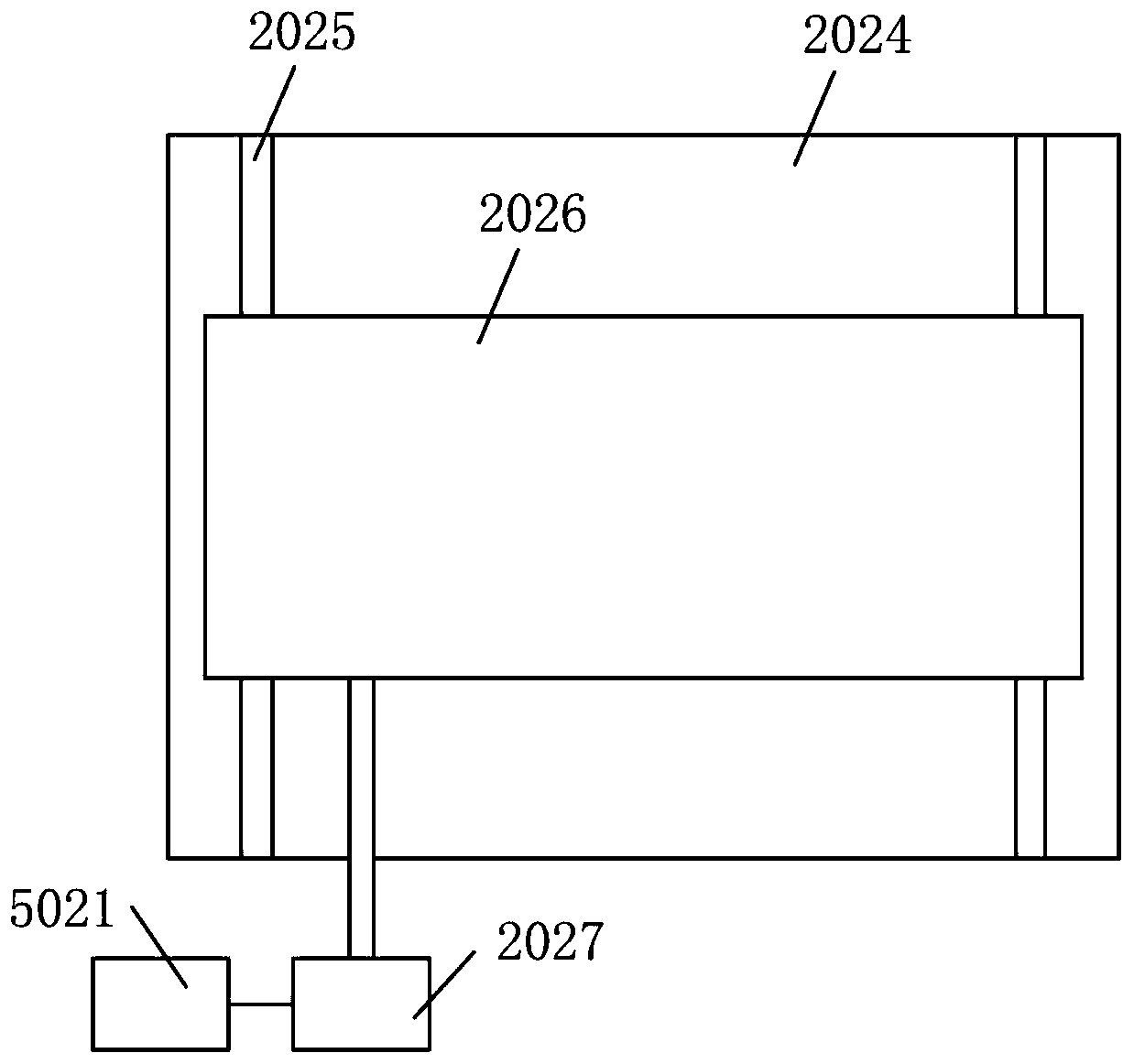

[0036] The clamping device 2 includes a clamper 201 and a clamper moving mechanism 202, the clamper moving mechanism 202 is arranged on the first side plate 102, one end of the clamper 201 is connected to the clamper mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com