Prefabricated prestressed concrete frame joint with amplified corner multi-stage energy consumption

A prestressing and concrete technology, applied in the direction of girders, truss structures, building components, etc., can solve the problems of damper performance degradation, difficulty in functioning, and large earthquake response, so as to eliminate residual deformation, avoid formation, and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

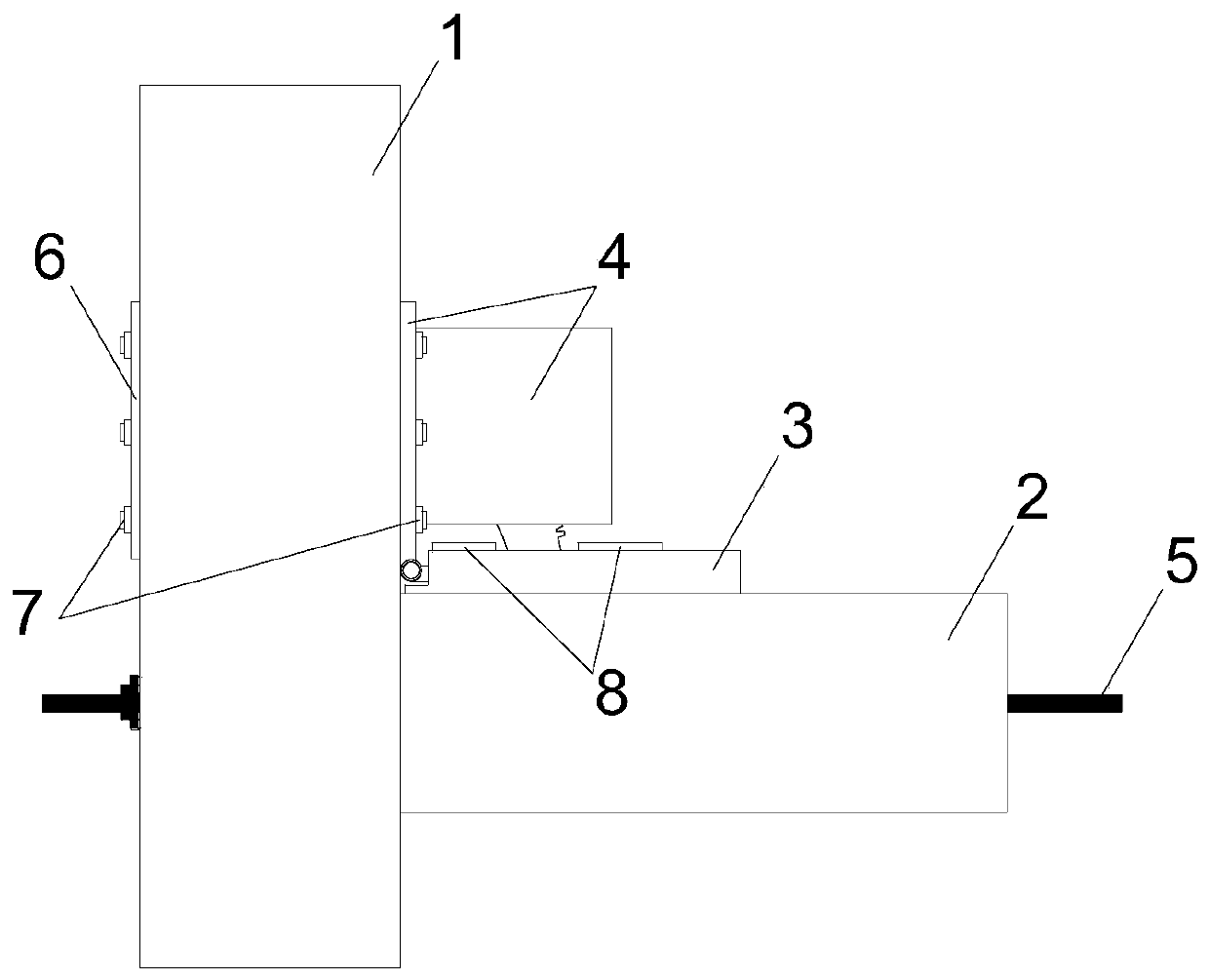

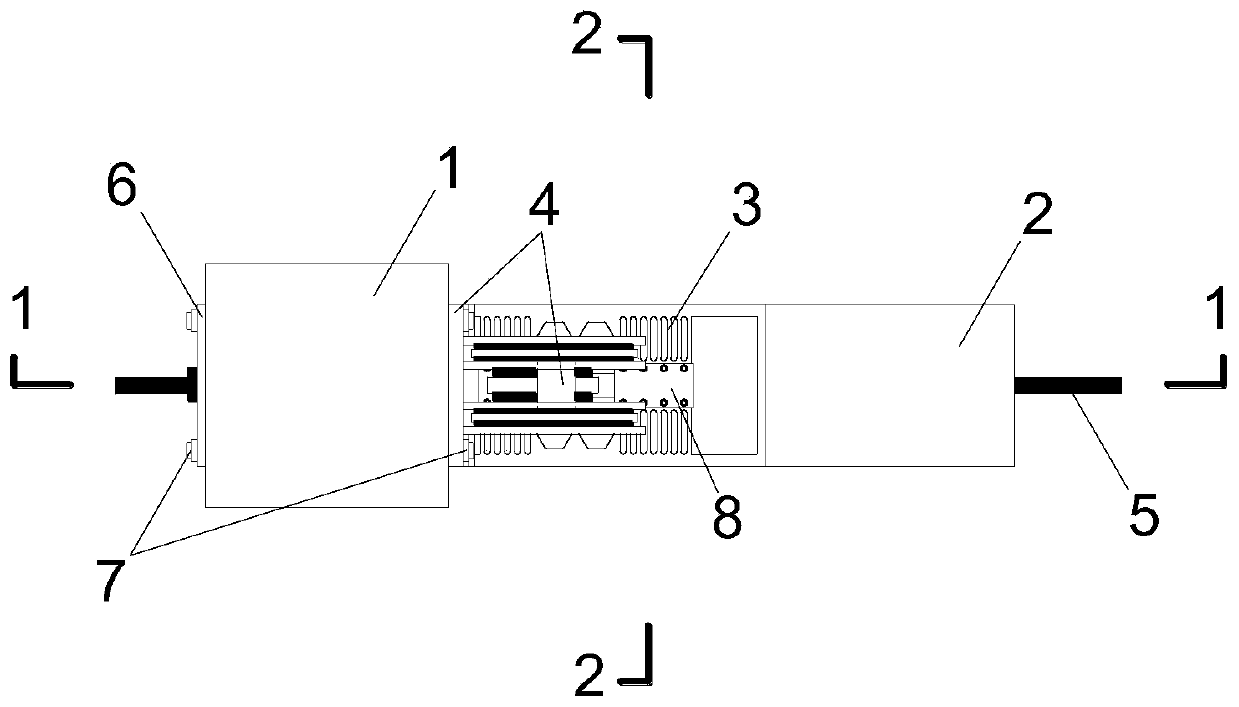

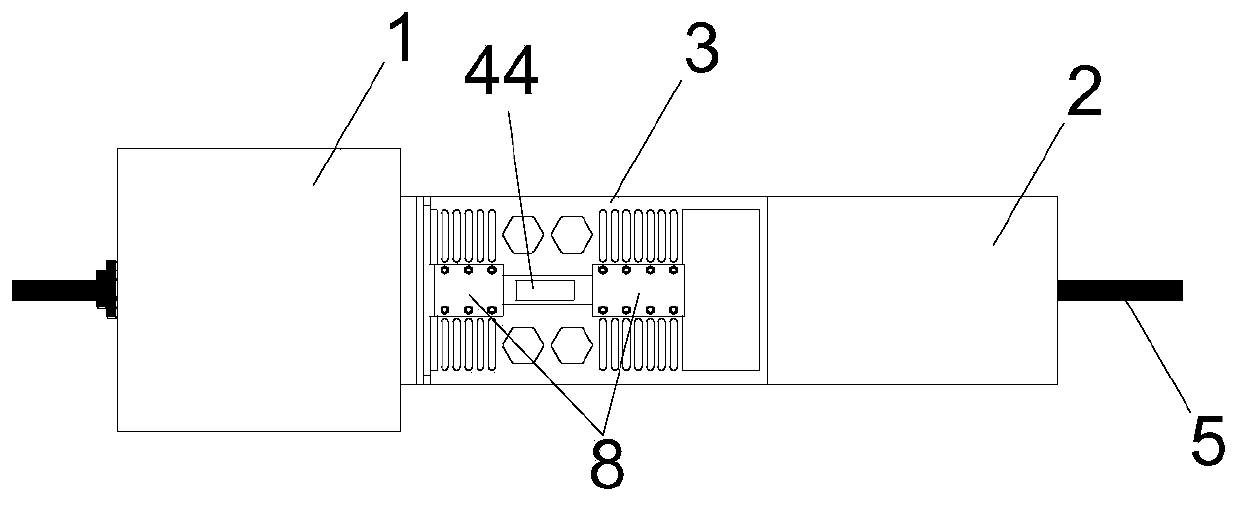

[0036] The technical solution of the present invention will be further described below in conjunction with the drawings.

[0037] A prefabricated prestressed concrete frame node with enlarged corners and multi-level energy consumption, including prefabricated reinforced concrete column 1, prefabricated reinforced concrete beam 2, beam end sliding device 3, enlarged corner joint shear damper 4, unbonded prestress The steel strand 5, the fixed steel plate 6, the high-strength bolts 7, and the energy-dissipating block 8; among them, the precast reinforced concrete column 1 and the precast reinforced concrete beam 2 are pre-compressed by the unbonded prestressed steel strand 5, and the two are mutually Vertical, forming the main body of the precast prestressed concrete frame joints;

[0038] The beam end sliding device 3 and the enlarged corner joint shear damper 4 constitute an energy dissipation device for the prefabricated prestressed concrete frame node; the beam end sliding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com