Cutterhead expanding excavation method using special-shaped cutter

A cutter head and cutting tool technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of reduced tool life, many contact surfaces, and unavailable tool bodies, etc., to prolong the service life and reduce secondary wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

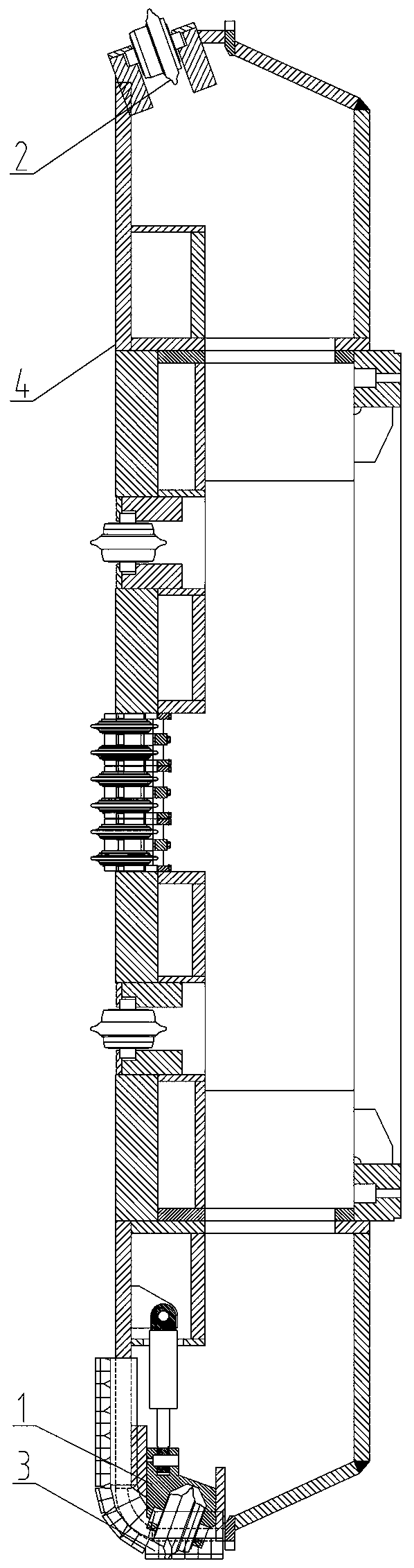

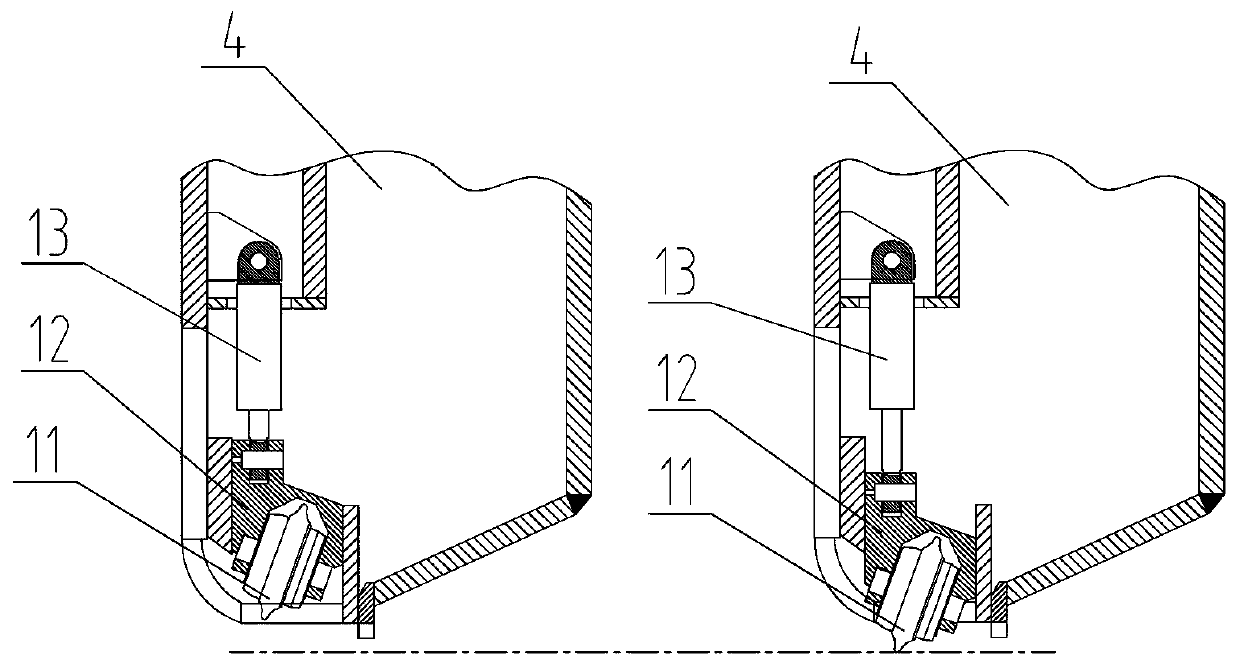

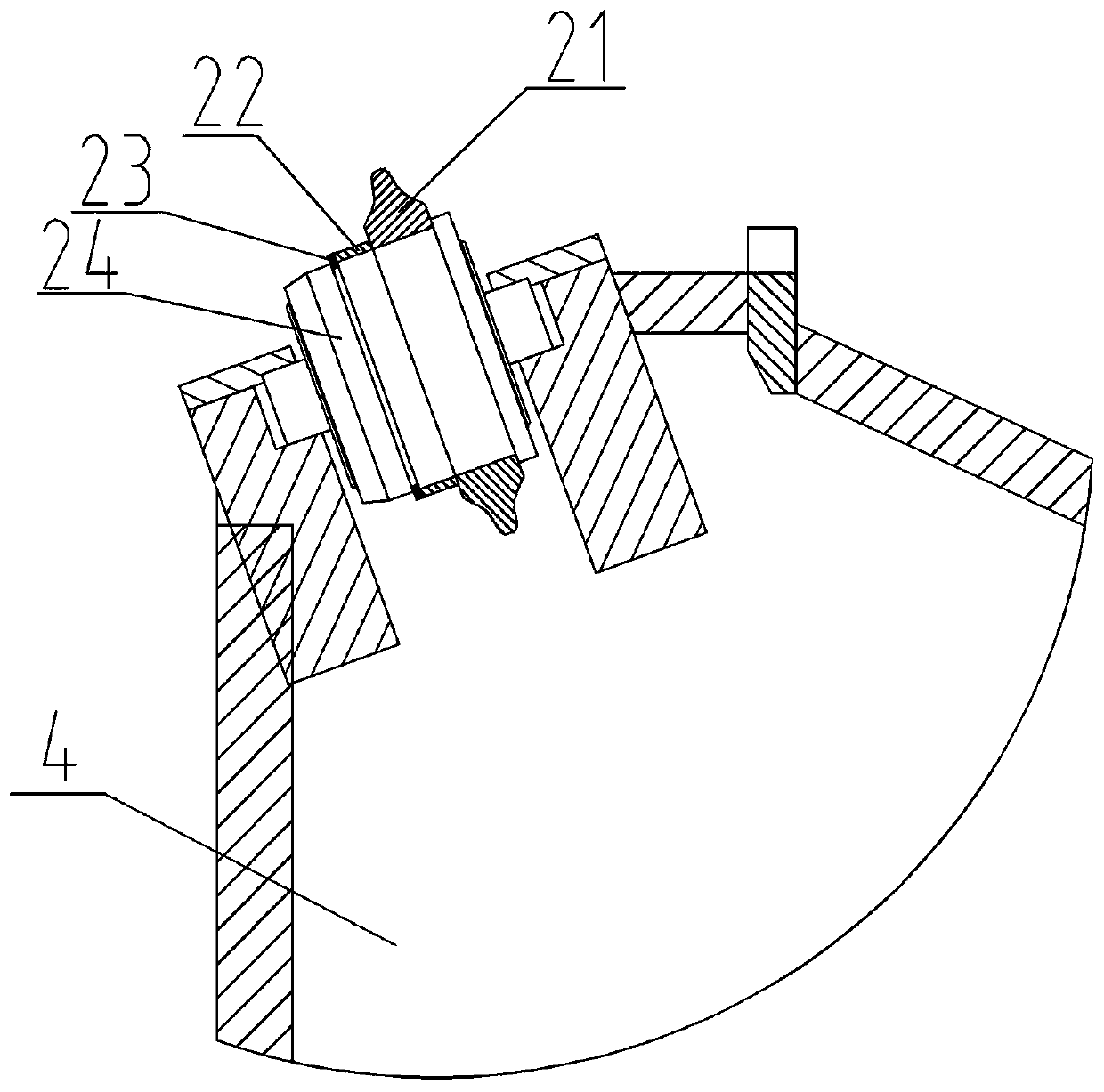

[0029] Embodiment 1: A kind of cutterhead enlarging method that adopts special-shaped cutter, see Figure 1-Figure 4 , including the following steps:

[0030] (1) At least one surrounding rock excavation hob 1 is arranged at the peripheral edge of the rock tunnel boring machine cutter head 4; the surrounding rock excavation hob 1 includes a hob cutter body 11, a movable knife seat 12 and a hydraulic cylinder 13. The hob cutter body 11 is fixed on the movable knife seat 12 by bolts, the bottom end of the hydraulic cylinder 13 is hinged with the cutter head 4, and the front end of the telescopic rod of the hydraulic cylinder 13 is hinged with the movable knife seat 12 .

[0031] (2) A side edge hob 2 is provided at the peripheral edge of the cutter head 4, and the side edge hob 2 includes a knife ring 21, a sleeve 22, a retaining ring 23 and a side edge cutter body 24. The blade cutter body 24 is installed near the outermost edge side of the cutter head 4, and the sleeve 22 tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com