Control method of supercharging function of gas water heater

A technology of a gas water heater and a control method, which is applied to fluid heaters, lighting and heating equipment, etc., and can solve problems such as easy misunderstandings by users, long warm-up cycles, burns, etc., and achieve the effect of avoiding false actions and improving bathing experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

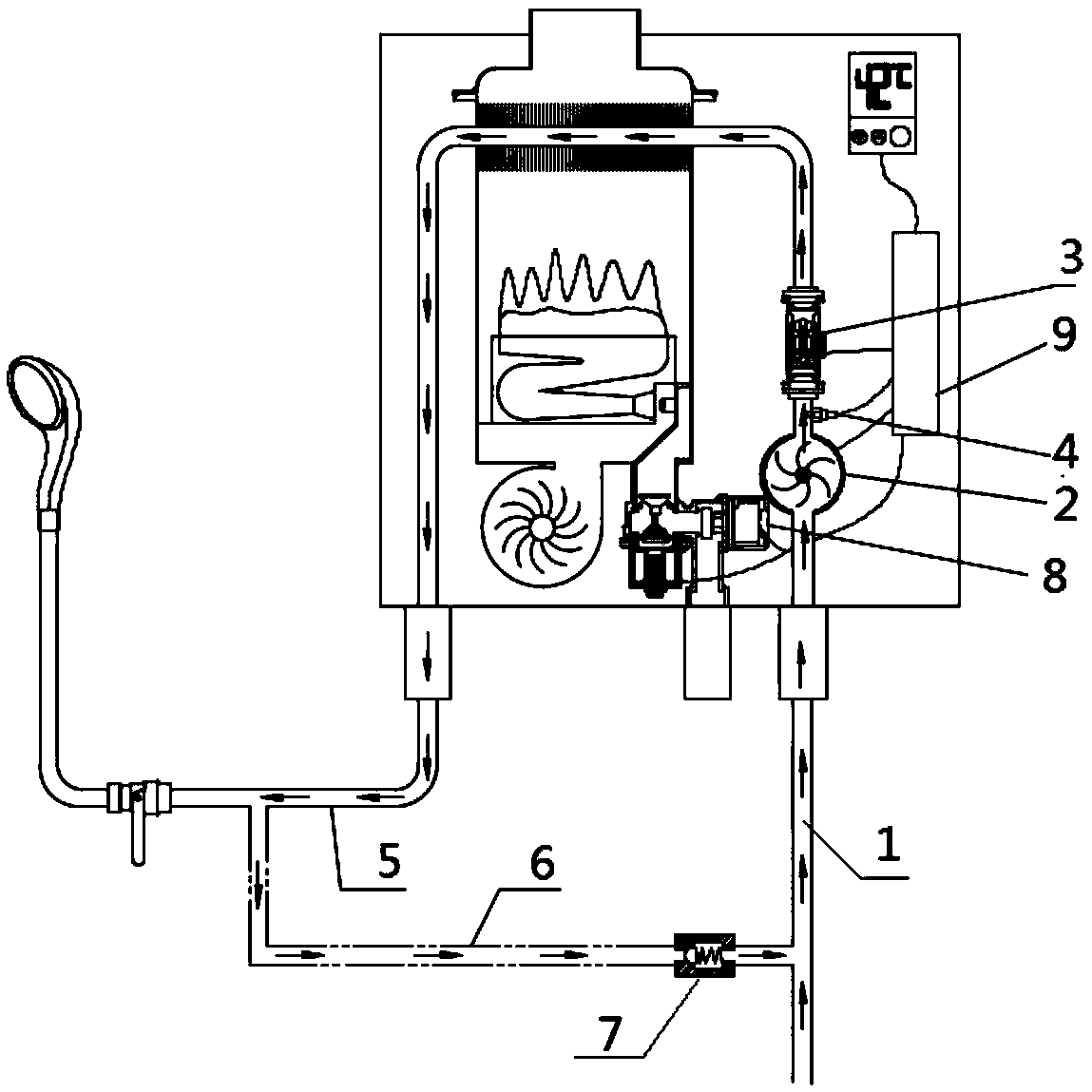

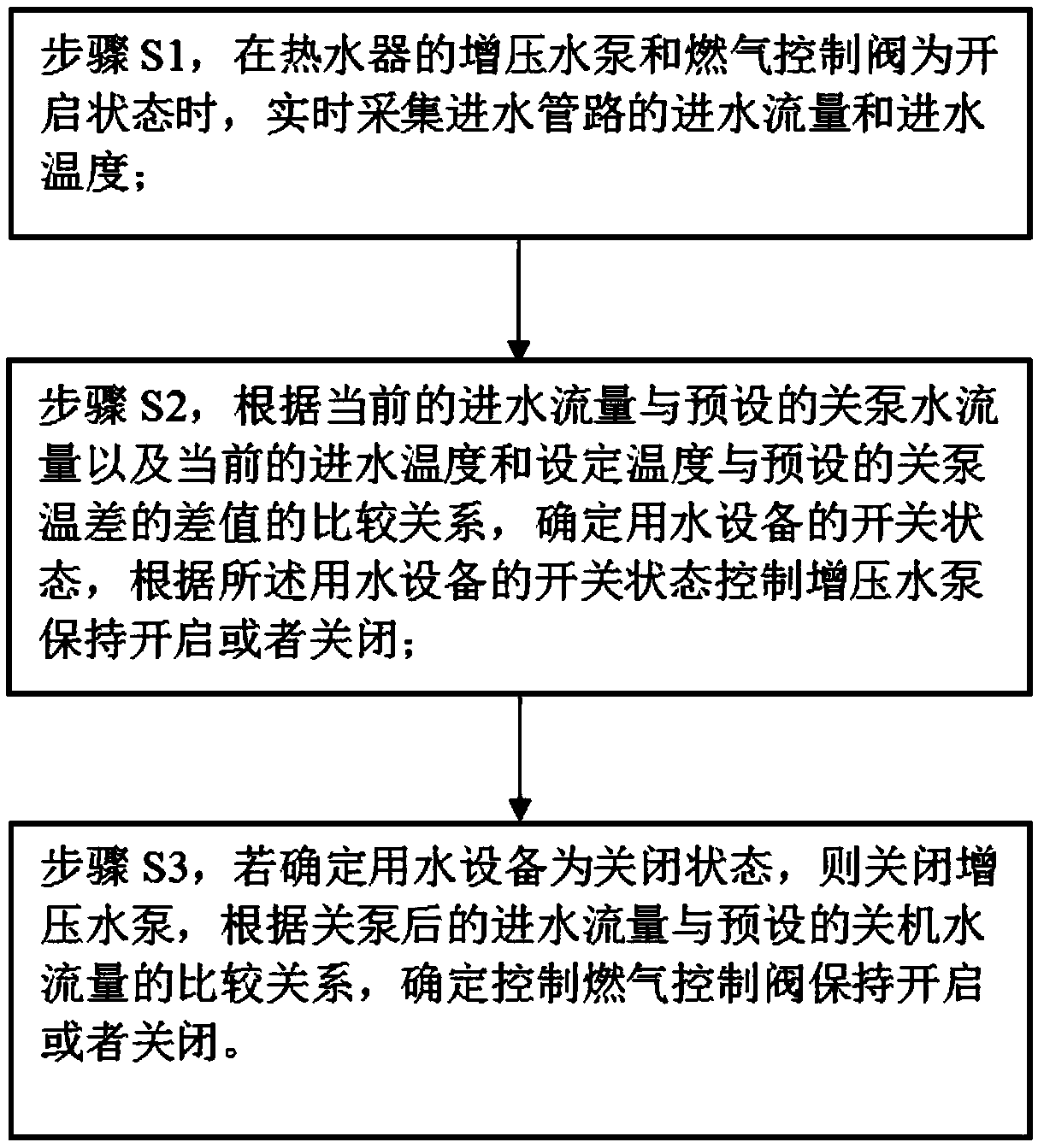

[0020] Embodiment 1 of the present invention provides a method for controlling the pressurization function of a gas water heater, referring to figure 1 , the gas water heater includes a water inlet pipeline 1, a booster pump 2, a water flow sensor 3, an inlet water temperature probe 4, an outlet pipeline 5, a water return pipeline 6, a one-way valve 7, a gas control valve 8, and a main controller 9; The booster pump 2, the water flow sensor 3, and the water inlet temperature probe 4 are set on the water inlet pipe 1, the outlet pipe 5 is used to connect the water equipment, and the return water pipe 6 connects the outlet pipe 5 with the water inlet pipe 1, and the return water pipe 6 is provided with a check valve 7 to make the water stored in the outlet pipeline 5 flow to the water inlet pipeline 1, and the booster water pump 2, water flow sensor 3, inlet water temperature probe 4, and gas control valve 8 are all connected to the main controller 9.

[0021] refer to figure ...

Embodiment 2

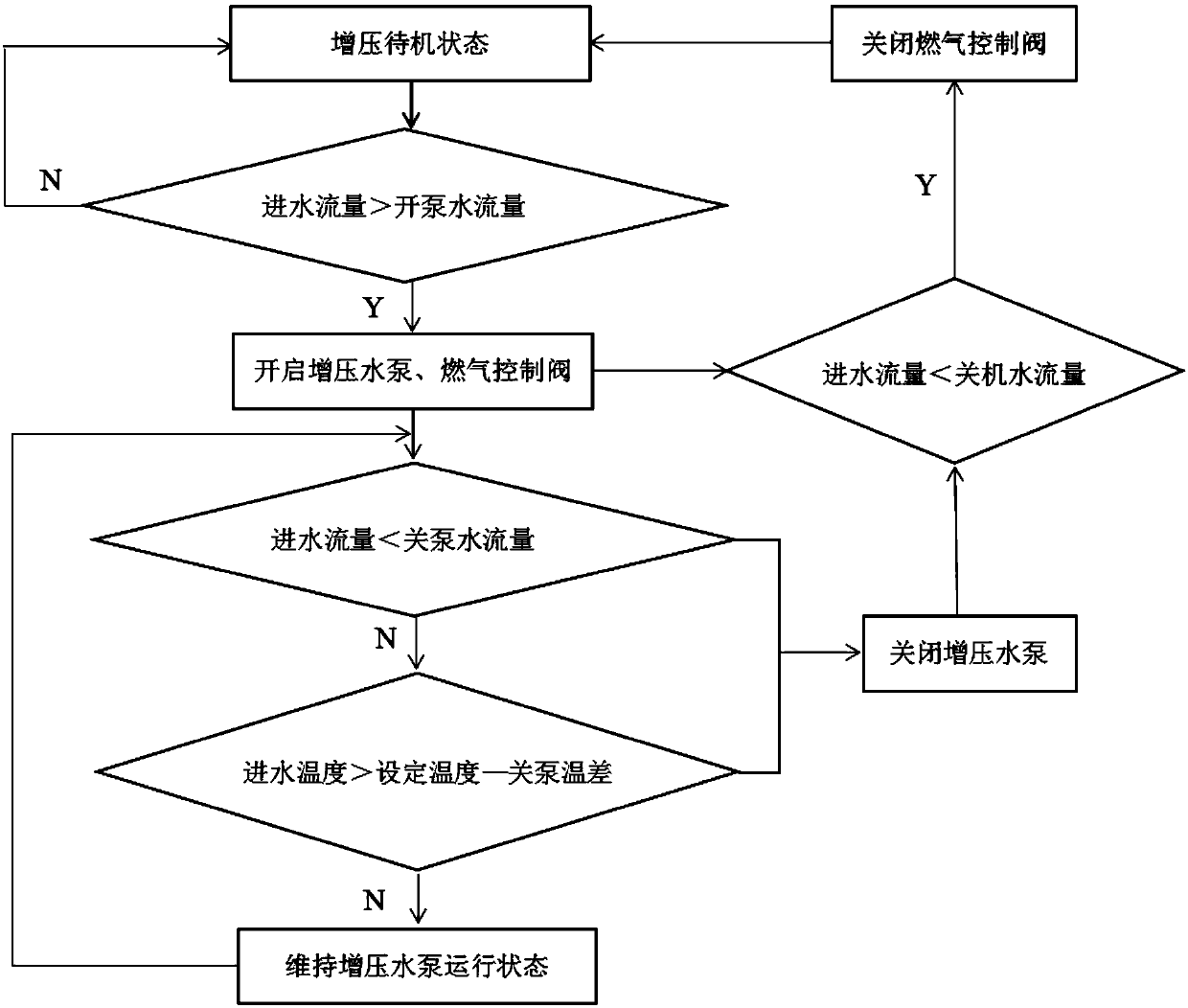

[0044] Embodiment 2 of the present invention provides a method for controlling the pressurization function of a gas water heater. In this embodiment, it is used in summer, and the set temperature is 35°C. Refer to image 3 , the specific working process is:

[0045] Step S1: When the booster pump 2 and the gas control valve 8 of the water heater are turned on, the water flow rate of the water inlet pipeline 1 is collected in real time as 3.5 L / min and the water inlet temperature is 33°C.

[0046] Step S2, if the water inlet flow rate is 3.5L / min and is greater than the preset shut-off water flow rate of 2.0L / min, then according to the comparative relationship between the current inlet water temperature and the difference between the set temperature and the preset shut-off temperature difference , determine the switch state of the water equipment, and control the booster water pump 2 to keep on or off according to the switch state of the water equipment.

[0047] Turn off the ...

Embodiment 3

[0055] Embodiment 3 of the present invention provides a method for controlling the pressurization function of a gas water heater. In this embodiment, it is used in winter and the set temperature is 50°C. Refer to image 3 , the specific working process is:

[0056] Step S1: When the booster pump 2 and the gas control valve 8 of the water heater are turned on, collect in real time that the water flow rate of the water inlet pipeline 1 is 3.5 L / min and the water inlet temperature is 20°C.

[0057] Step S2, if the water inlet flow rate is 3.5L / min and is greater than the preset shut-off water flow rate of 2.0L / min, then according to the comparative relationship between the current inlet water temperature and the difference between the set temperature and the preset shut-off temperature difference , determine the switch state of the water equipment, and control the booster water pump 2 to keep on or off according to the switch state of the water equipment.

[0058] Turn off the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com