A Controlled Blasting Method for Weak Interlayer Geological Slope

A technology for controlling blasting and weak interlayers, applied in blasting and other directions, can solve problems such as over-excavation, poor blasting effect, and high maintenance costs, and achieve the effects of avoiding secondary repairs, improving construction quality, and reducing construction and later maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

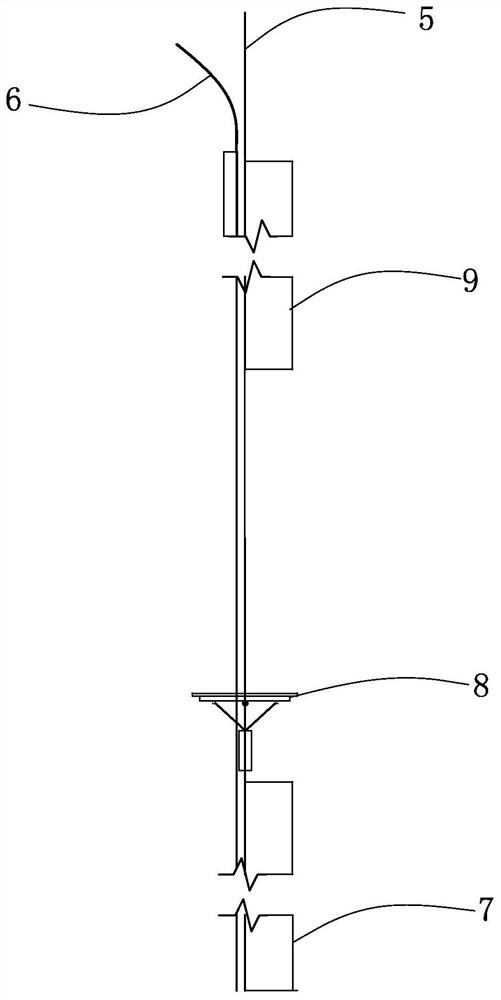

[0020] The method of the present invention will be described below in conjunction with the accompanying drawings and a specific embodiment.

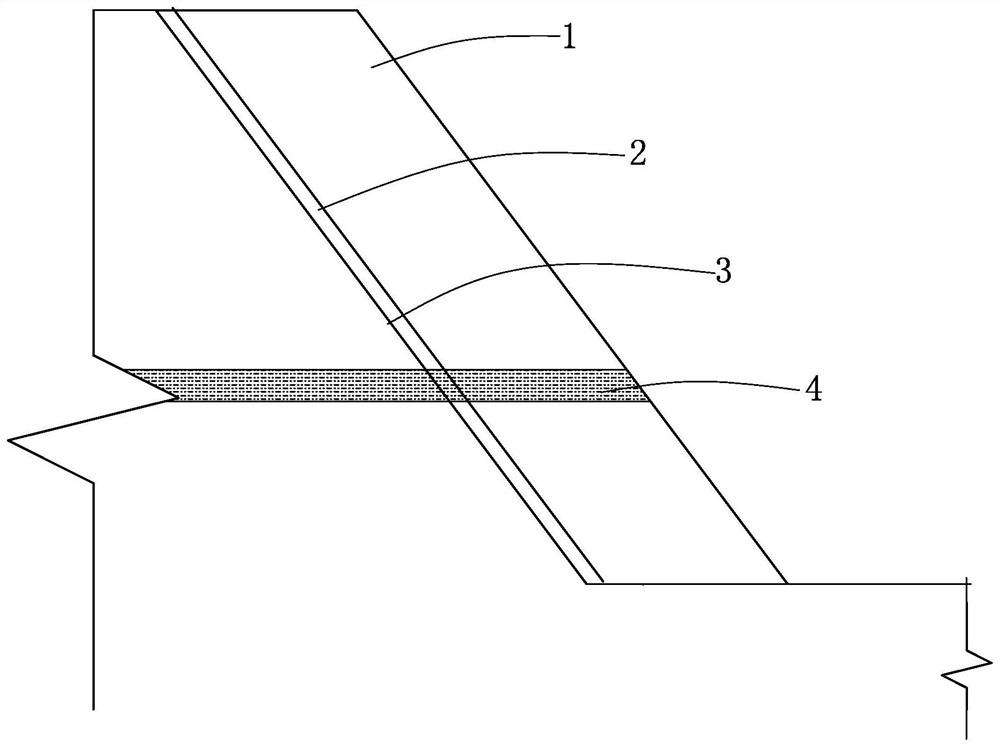

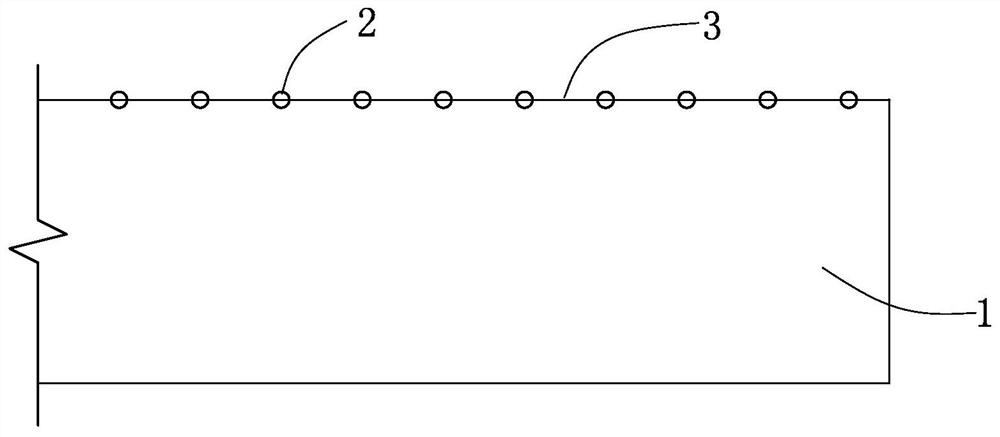

[0021] Such as figure 1 , figure 2 As shown, a highway project constructed by the applicant is located in a weak interlayer geological environment, and blasting construction is adopted for roadbed excavation. A certain thickness of light blasting layer 1 is reserved after blasting in the main blasting area, creating an empty surface for slope control blasting.

[0022] The designed excavation depth of the subgrade is 10m, the slope slope is 1:0.75, the slope adopts smooth blasting, the blastholes 2 are arranged along the slope excavation line 3, and Φ70mm blastholes are used, the spacing is 15 times the blasthole diameter, and the blastholes are inclined The angle is the same as that of the side slope, and the hole depth is 13m.

[0023] The integrity of the rock mass of the slope is good, but there is a broken zone 4 with a width of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com