Hammering device, system and method for dynamic characteristic analysis of stator winding end of large condenser

A technology of stator winding and dynamic characteristics, applied in the field of testing, can solve the problems of unstable excitation intensity, different working effects, affecting test efficiency, etc., and achieve the effects of accurate fixed results, ingenious technical ideas, and easy technical implementation.

Active Publication Date: 2022-03-18

ELECTRIC POWER RES INST OF EAST INNER MONGOLIA ELECTRIC POWER +1

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the strength of artificial hammering excitation is not fixed, and the working effect varies from person to person. People are prone to fatigue after a long test time, which affects the test efficiency.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0063] In order to enable those skilled in the art to understand the technical solutions of the present disclosure more clearly, the technical solutions of the present disclosure will be described in detail below in conjunction with specific examples and comparative examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

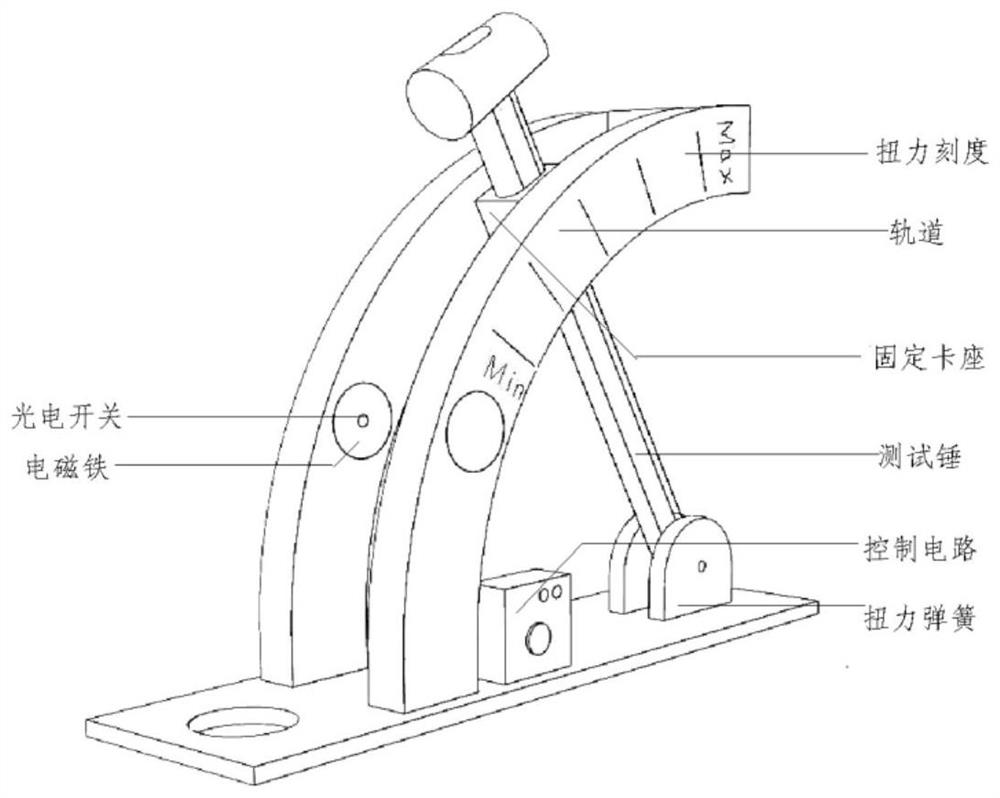

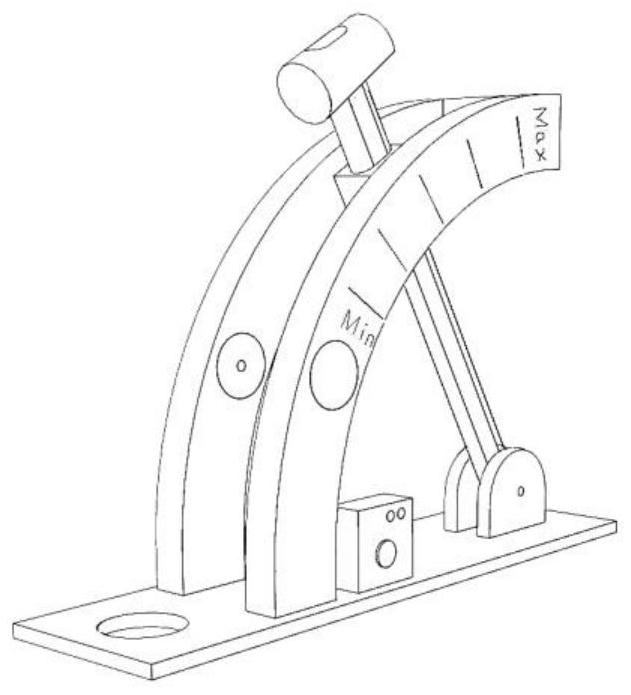

A hammering device, system and method for analyzing the dynamic characteristics of the stator winding end of a large-scale condenser, the hammering device is characterized in that it includes a test hammer, and a fixed card seat is arranged on the test hammer, and the opposite sides of the fixed card seat are respectively installed with Movable tab; the test hammer moves in a track formed by two oppositely arranged arc bars, and electromagnets are respectively embedded in the relative positions of the inner surfaces of the two arc bars, and the electromagnets and the inner surfaces of the arc tracks are in the In the same plane; when the detection and control circuit detects the drop of the test hammer, the control electromagnet is energized, and the movable tabs on both sides of the fixed deck when the test hammer rebounds and goes up are attracted, and the test hammer is fixed. The hammering device of the present disclosure utilizes a detection and control circuit to realize that the test hammer is bounced up and then fixed after a hammering test once, avoiding secondary falling, and ensuring measurement accuracy.

Description

technical field [0001] The disclosure relates to the technical field of testing, in particular to a hammering device, system and method for analyzing the dynamic characteristics of the end of a stator winding of a large-scale condenser. Background technique [0002] In order to assess whether the dynamic characteristics of the stator winding end of the large-scale condenser engineering unit meet the standard requirements, it is necessary to test the dynamic characteristics of the stator winding end of a single unit. [0003] For the test of the dynamic characteristic analysis of the stator winding end of the large condenser, in this test, the traditional test method uses artificial hammering to generate the excitation signal. However, the strength of artificial hammering excitation is not fixed, and the working effect varies from person to person. People are prone to fatigue after a long test time, which affects the test efficiency. Contents of the invention [0004] The ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N3/307G01N3/02G01R31/34

CPCG01N3/307G01N3/02G01R31/346

Inventor 左秀江钱文晓郭金刚王延伟王钰胡志帅安义岩党乐陈雅琦佟敏刘慧李博刘天奇胡全义窦海燕张阳张欣伟王博端木天翔

Owner ELECTRIC POWER RES INST OF EAST INNER MONGOLIA ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com