Battery module and wire harness plate assembly thereof and transfer conductive bar

A battery module and conductive row technology, applied in battery pack components, electrical components, conductive connections, etc., can solve the problems of battery module arrangement adjustment, space waste, etc., so as to solve the space waste and reduce the occupied space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

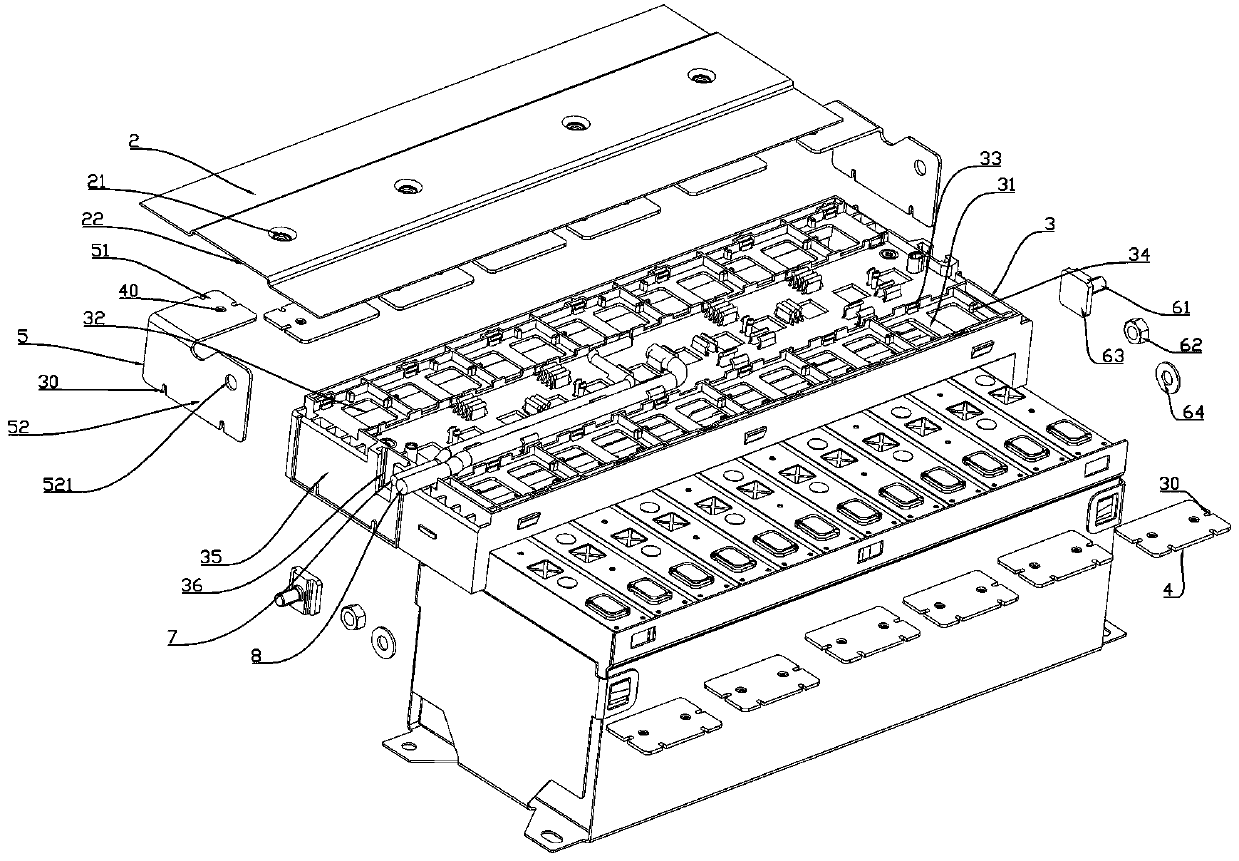

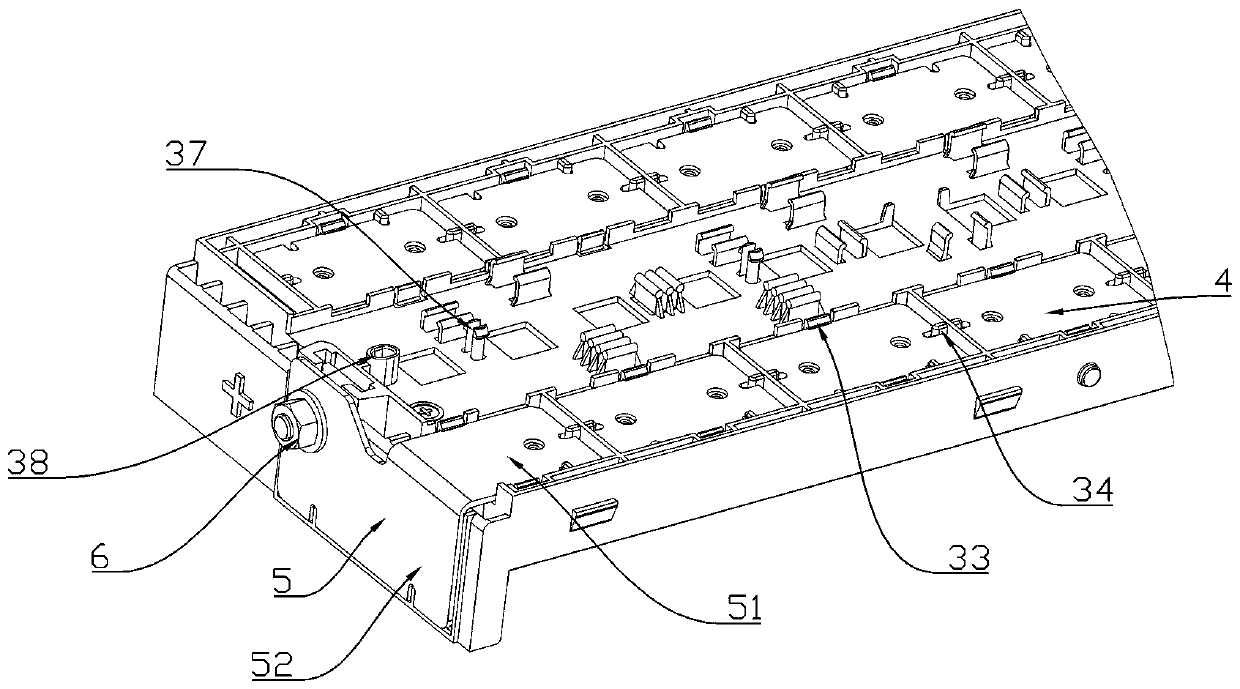

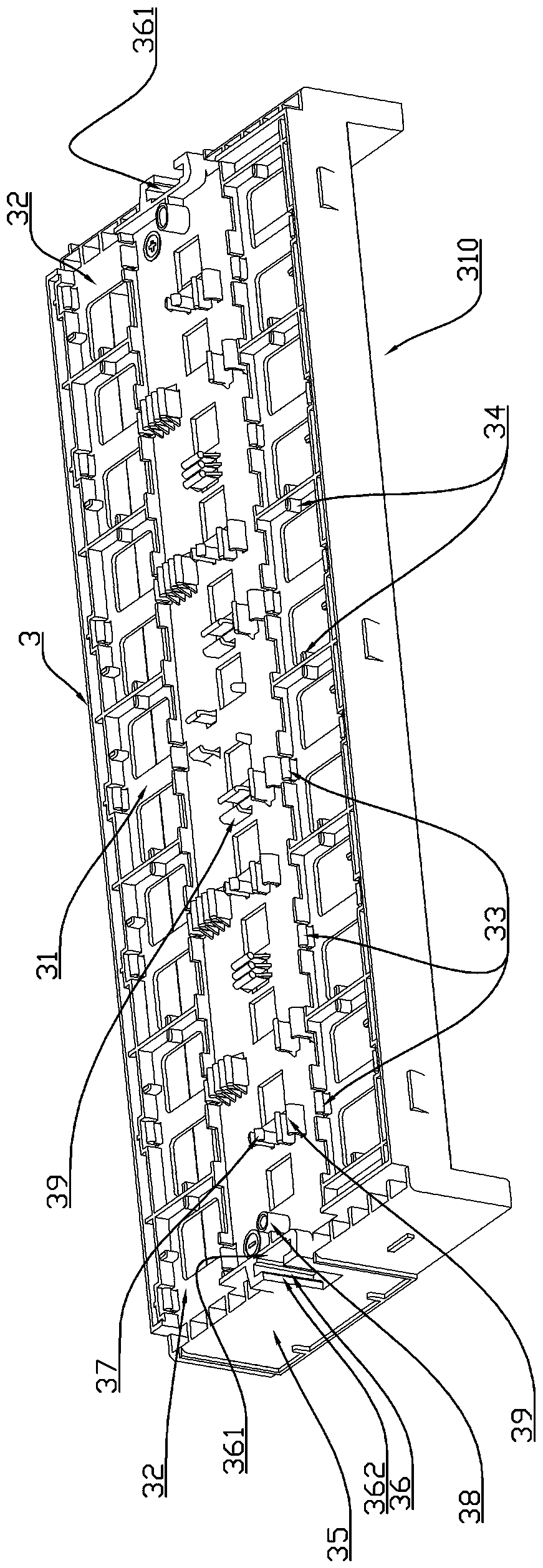

[0053] Specific embodiment 2 of the battery module of the present invention. In this embodiment, the battery module includes a battery unit and a wire harness board assembly. 1. The battery cell conductive bar, the transfer conductive bar is equipped with module output terminals, and the transfer conductive bar includes the battery unit connection part fixed on the top of the harness board and conductively connected to the battery unit and the lateral turning part fixed on the side of the harness board The connection part, the output terminal of the module is arranged on the side of the battery module, and the output terminal of the module is arranged on the side transfer part. The number of battery cells can be set as required, and can be at least two. In addition to adopting the form in the specific embodiment 1, the above-mentioned components can also adopt other commonly used forms in the art. For example, the output terminal of the module can be a terminal post welded on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com