Universal type assembly mechanism for nozzle installation

An assembly mechanism and general-purpose technology, applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of poor adaptability, low production efficiency, and lack of versatility, so as to achieve strong practicability and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

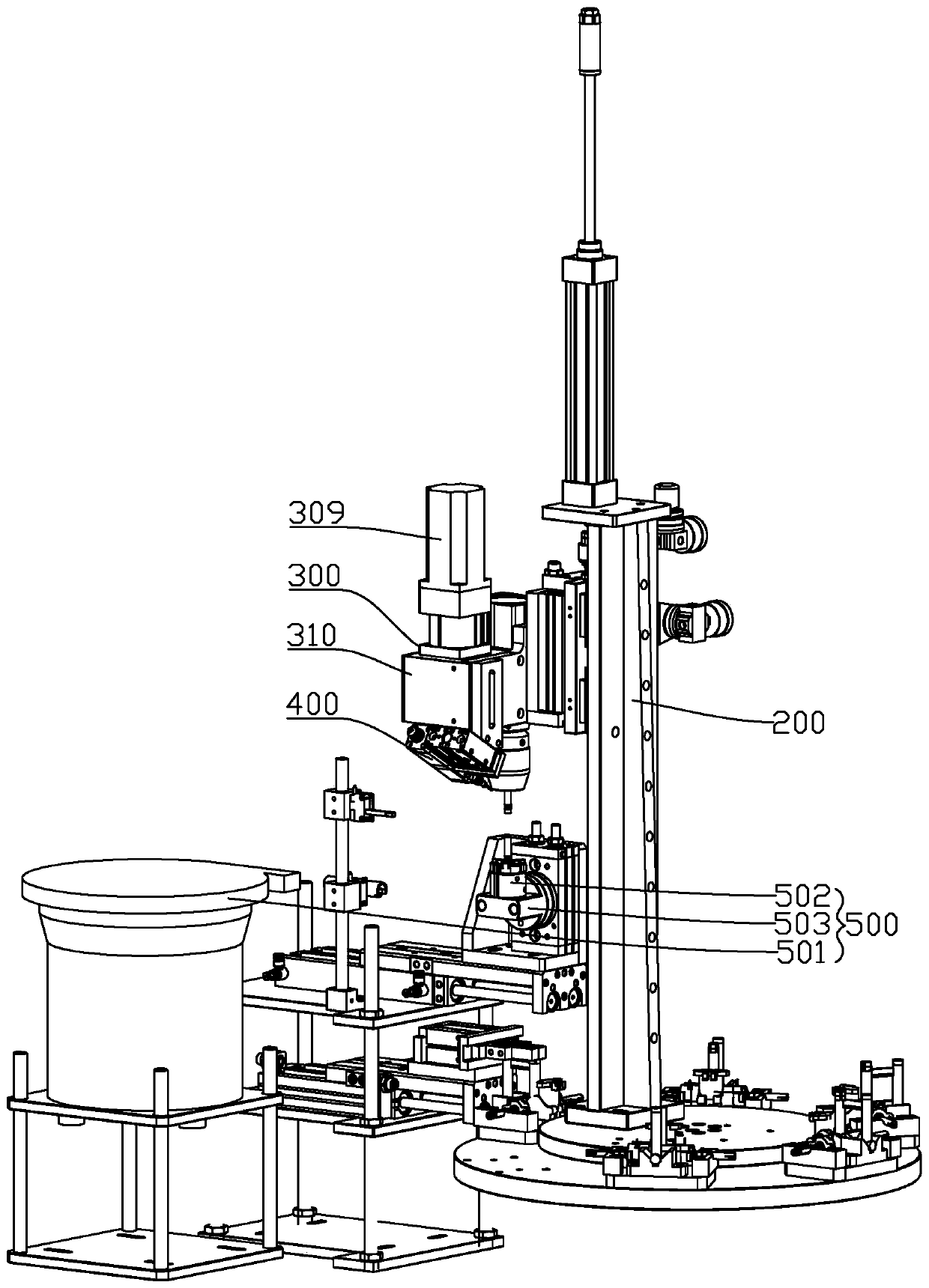

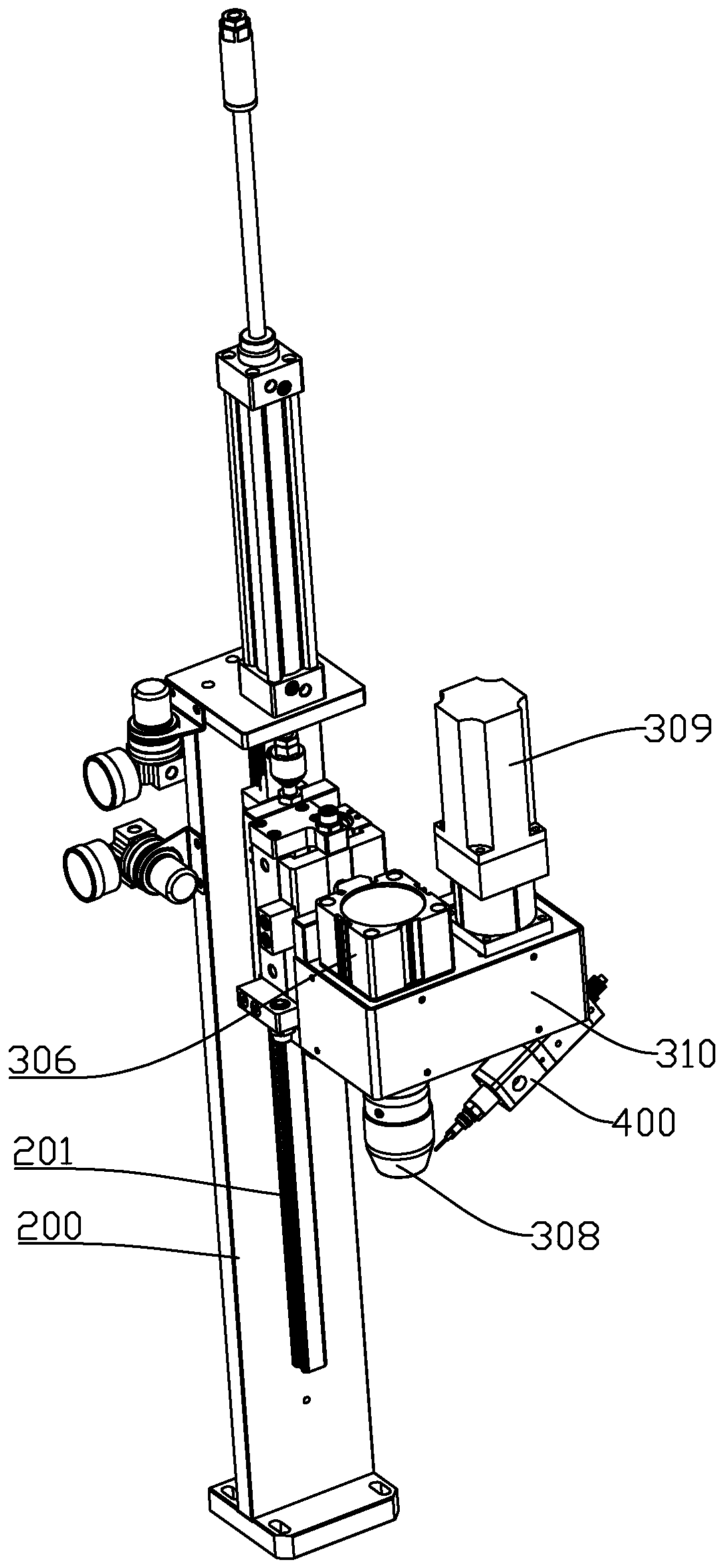

[0028] refer to figure 2 , the present invention provides a general-purpose assembly mechanism for nozzle installation, which is provided with a nozzle feeding device 200 and a nozzle clamping and rotating device 300 installed thereon, and the nozzle clamping and rotating device 300 includes a The clamping device of the nozzle circular pipe section 103 and the rotating device controlling the rotation of the clamped nozzle 100 .

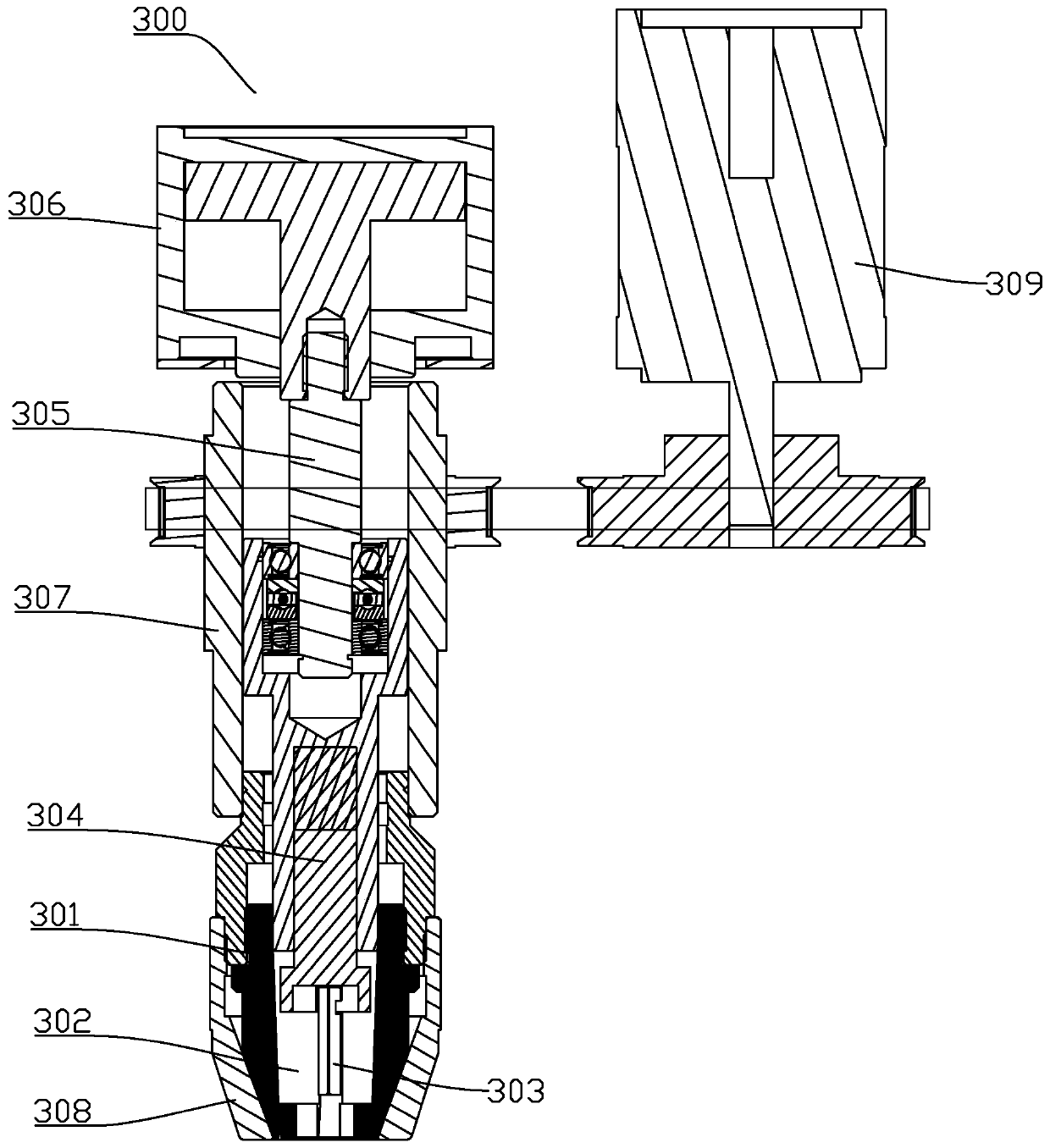

[0029] Specifically, such as image 3 and Figure 4 As shown, the clamping device is provided with a chuck 301 and a clamping drive mechanism, and the chuck 301 is provided with three jaws 302 opened in a natural state around an axis, and between two adjacent jaws 302 There is a certain gap between them, and the clamping drive mechanism is provided with a slider 303 between every two adjacent jaws 302, and the slider 303 moves toward the opening end of the jaws 302 along the axis distributed along the jaws 302 The two adjacent clamping jaws 302 ca...

Embodiment 2

[0042] This embodiment takes Embodiment 1 as the main body, and the difference is that the universal assembly mechanism for nozzle assembly in this embodiment is also provided with a nozzle feeding device 500, such as Image 6 As shown, the nozzle feeding device 500 includes a nozzle feeding vibrating plate 501 and a nozzle taking device, and the nozzle taking device is used to clamp the nozzle 100 from the output end of the nozzle feeding vibrating plate 501 and transport it to a set position for clamping of the clamping device.

[0043] like Image 6 As shown, the nozzle retrieving device is provided with a rotating mounting seat 503, which is driven by a swing cylinder, and the rotating mounting seat 503 is provided with a three-jaw chuck 502, and the three-jaw chuck 502 can be The swivel mount 503 rotates to the horizontal and vertical states. Since the vibrating plate, the oscillating cylinder, and the three-jaw chuck 502 all belong to common knowledge, they will not be...

Embodiment 3

[0047] This embodiment takes Embodiment 1 as the main body, and the difference is that the universal assembly mechanism for nozzle assembly in this embodiment is also provided with a valve body fixing device 600, and the valve body fixing device 600 corresponds to the nozzle feeding device 200 set and used to fix the valve body.

[0048] like Figure 7 As shown, since the air outlet is formed on the valve body by setting the air pipe, and in actual production and processing, the valve body is fixed by tooling, so the valve body fixing device 600 in this embodiment is only used to fix the valve body on the valve body. trachea. As shown in the figure, the valve body fixing device 600 is provided with a pair of splints 601, and a groove adapted to the air pipe is arranged between the two splints 601, and the two splints 601 can be opened and closed by driving the cylinder. At the same time, the groove centers of the two splints 601 coincide with the distribution axes of the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com