Film plating method of automotive interior

A technology for automotive interiors and interiors, which is applied in the field of coatings for automotive interiors. It can solve problems such as uneven thickness of the electroplating layer, failure to meet the design size, and failure to meet assembly requirements, etc., to achieve enhanced wear resistance and uniform coating thickness. control, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

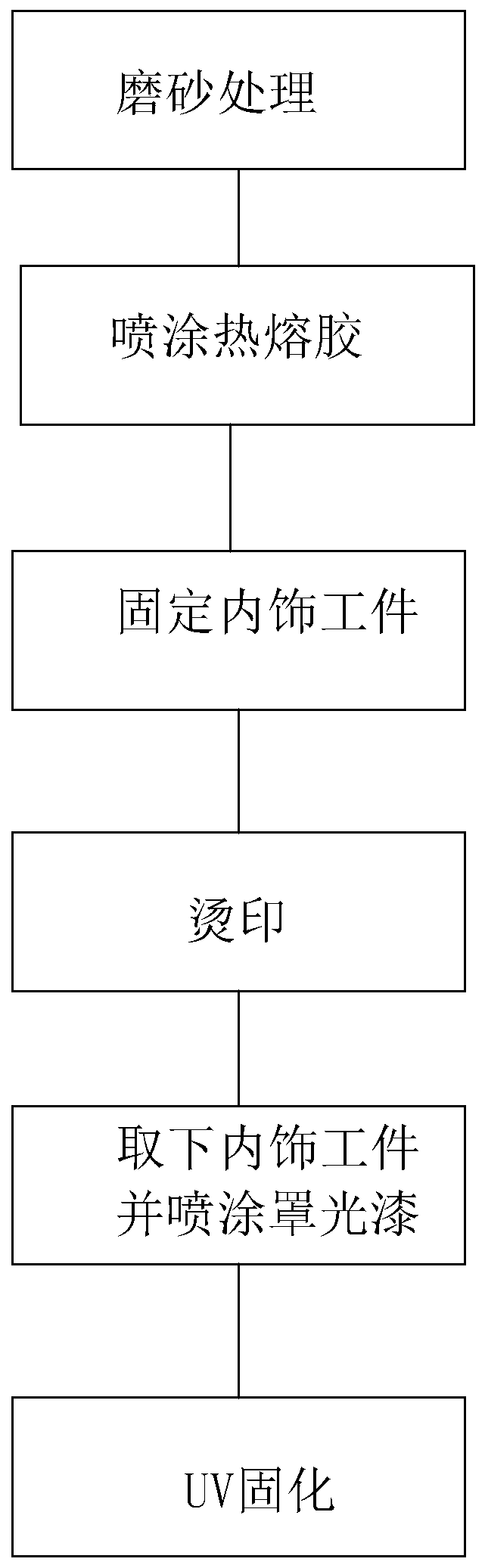

[0033] Embodiment: a kind of coating method of automobile interior, as figure 1 , First, use W7 sandpaper to frost the surface of the interior workpiece to improve the roughness of the surface of the interior workpiece, and spray a layer of hot melt adhesive on the surface of the frosted interior workpiece. The hot melt adhesive is sprayed on the The surface of the interior workpiece is sufficient, and the mist hot melt adhesive will be adsorbed in the small grooves on the surface of the rough interior workpiece. Then fix the interior workpiece on the hot stamping machine through a mold whose shape matches the interior decoration workpiece, and adjust the position of the interior decoration workpiece so that it corresponds to the silicone plate on the hot stamping machine to prepare for hot stamping.

[0034] Such as figure 1 , when the hot stamping machine drives the silicone plate to move down and conflict with the film, the silicone plate will absorb the film through negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com