Preparation method for obtaining orthorhombic or monoclinic molybdenum trioxide

A technology of molybdenum trioxide and monoclinic crystal, which is applied in chemical instruments and methods, molybdenum oxide/molybdenum hydroxide, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the problems of high price and high catalyst cost , to achieve the effect of low cost, simple preparation method and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing molybdenum trioxide in orthorhombic crystal form and monoclinic crystal form, which specifically includes the following steps:

[0026] S1. Smash the discarded silicon-molybdenum rod resistance wire into a block, and then ball-mill it into a nano-scale powder;

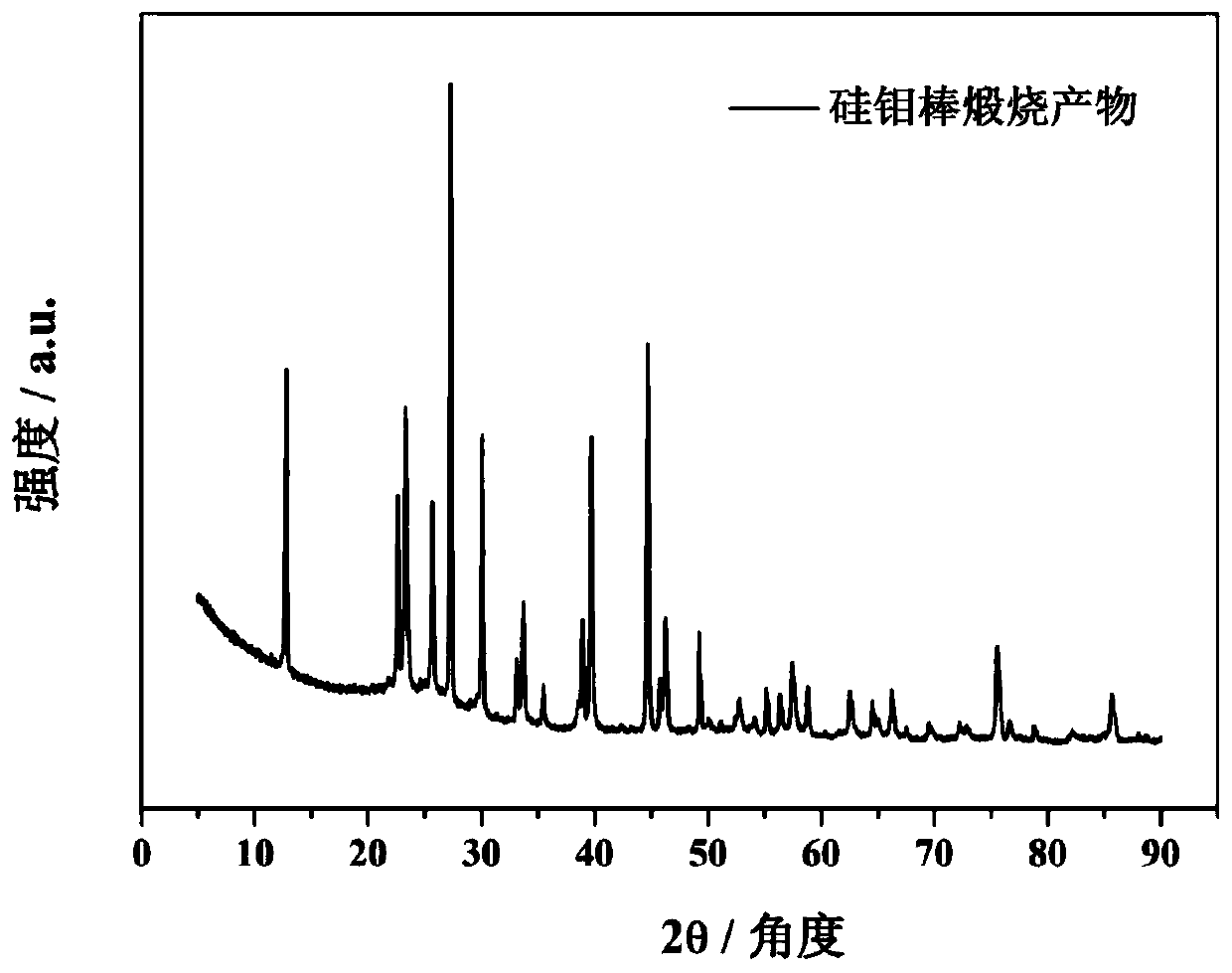

[0027] S2. Calcining the ball-milled nanoscale powder in an environment without protective gas, the calcination temperature is 575-650° C., and the calcination time is 60-240 minutes to obtain a mixture;

[0028] S3. Put the calcined mixture obtained in step S2 in a mixed solution of hydrofluoric acid and nitric acid with a ratio of 5:1 to 5:3 or a mixed solution of hydrofluoric acid and hydrogen peroxide with a ratio of 5:1 to 5:3 Soak for 60-480 minutes, wash with distilled water and absolute ethanol several times, filter, and dry to obtain molybdenum trioxide in different crystal forms, specifically

[0029] When the proportioning ratio of hydrofluoric acid and n...

Embodiment 1

[0033] S1. Smash the discarded silicon-molybdenum rod resistance wire into a block, and use a ball mill to grind it into a nano-scale powder;

[0034] S2. Calcining the ball-milled nanoscale powder in an environment without protective gas, the calcination temperature is 575° C., and the calcination time is 240 minutes to obtain a mixture;

[0035] S3. Soak the calcined mixture obtained in step S2 in a mixture of hydrofluoric acid and nitric acid at a ratio of 5:1 for 480 minutes, wash with distilled water and absolute ethanol several times, filter, and dry to obtain An orthorhombic molybdenum trioxide catalyst with oxygen catalytic activity. Such as figure 2 As shown, the obtained miscellaneous molybdenum trioxide is off-white solid powder.

Embodiment 2

[0037] S1. Smash the discarded silicon-molybdenum rod resistance wire into a block, and use a ball mill to grind it into a nano-scale powder;

[0038] S2. Calcining the ball-milled nanoscale powder in an environment without protective gas, the calcination temperature is 650° C., and the calcination time is 60 minutes to obtain a mixture;

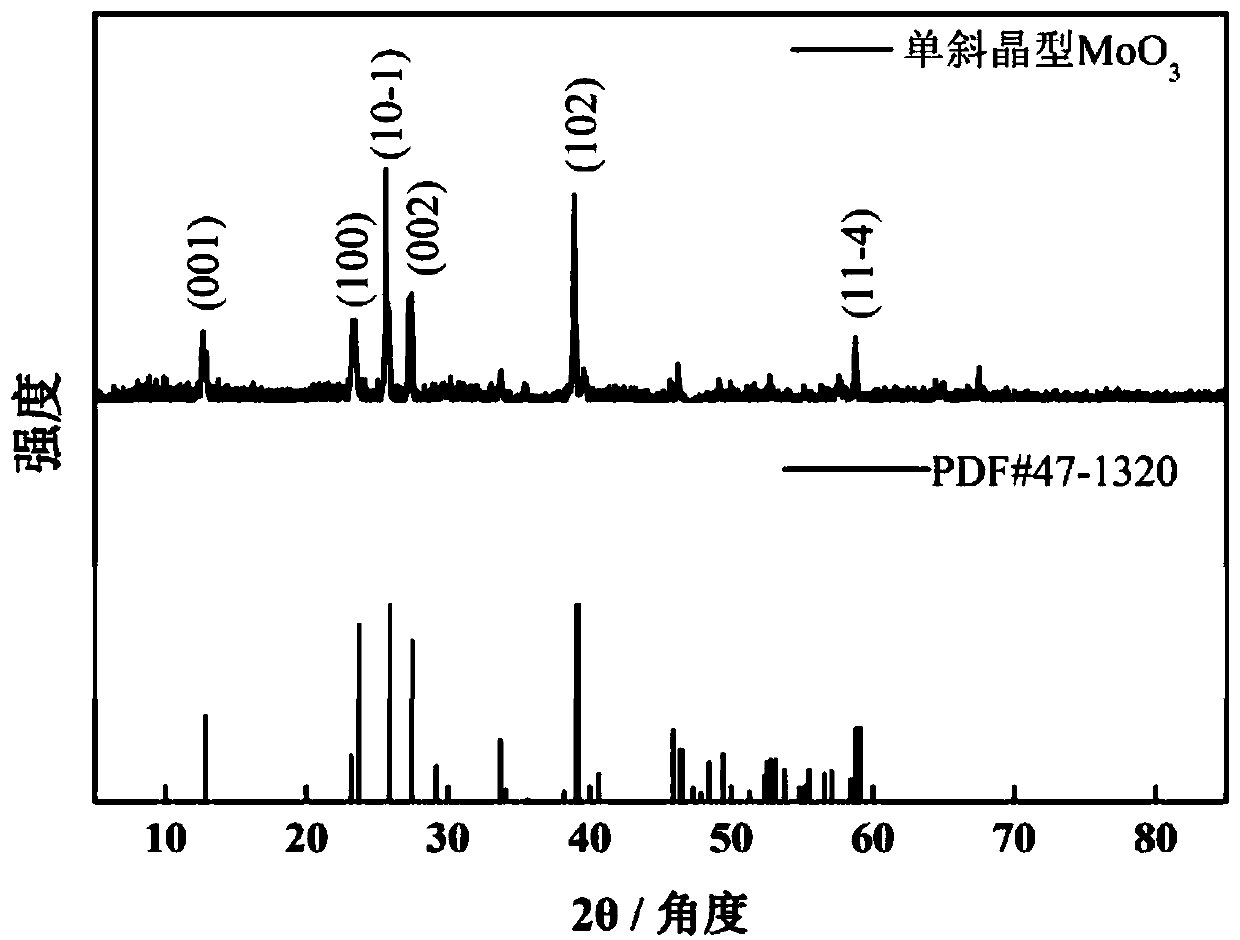

[0039] S3. Soak the calcined mixture obtained in step S2 in a mixture of hydrofluoric acid and nitric acid with a ratio of 5:3 for 60 minutes, wash with distilled water and absolute ethanol several times, filter, and dry to obtain Oxygen catalytically active monoclinic molybdenum trioxide catalysts, such as image 3 As shown, it complies with the PDF#47-1320 card.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com