Sludge dewatering extrusion die

A technology of sludge dehydration and extrusion die, which is applied in the direction of water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. It can solve the problems of affecting the extrusion effect, low drainage efficiency, and reduced sludge moisture content, etc. problems, to achieve the effect of improving drainage efficiency, improving operating efficiency, and shortening operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

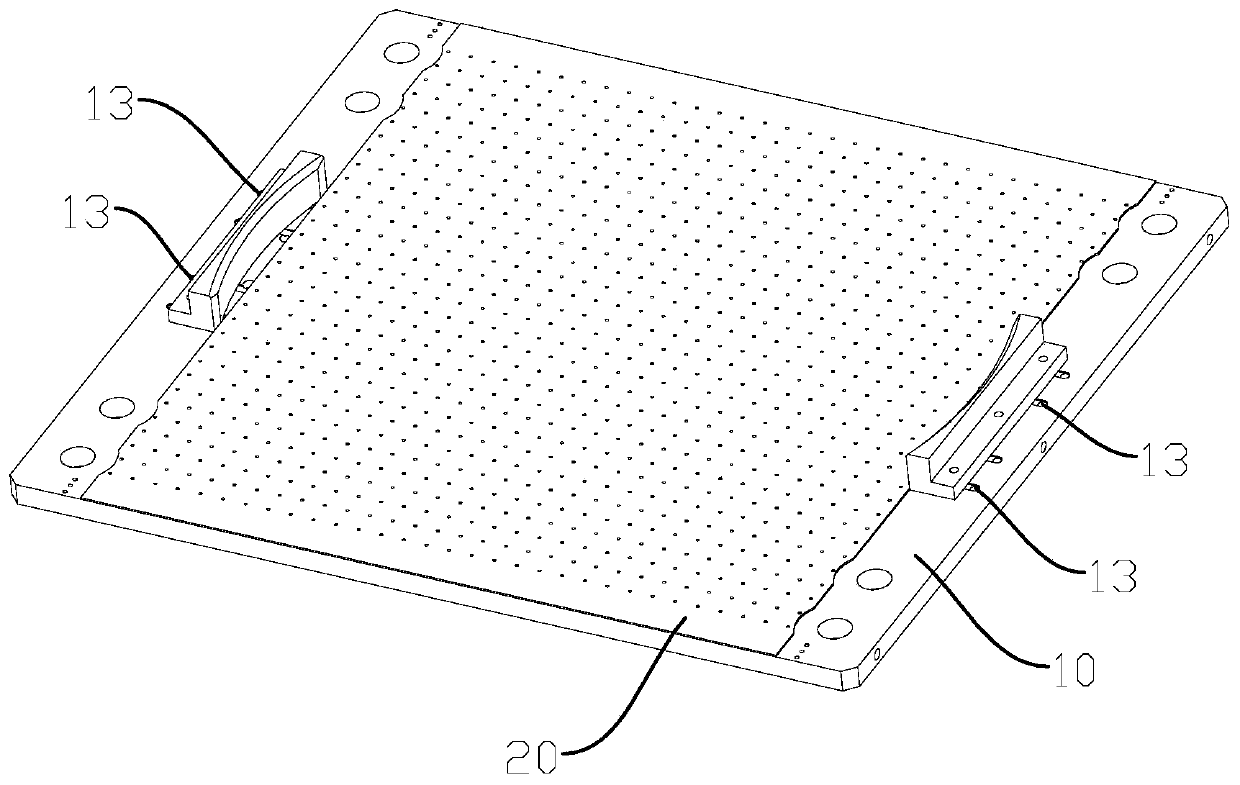

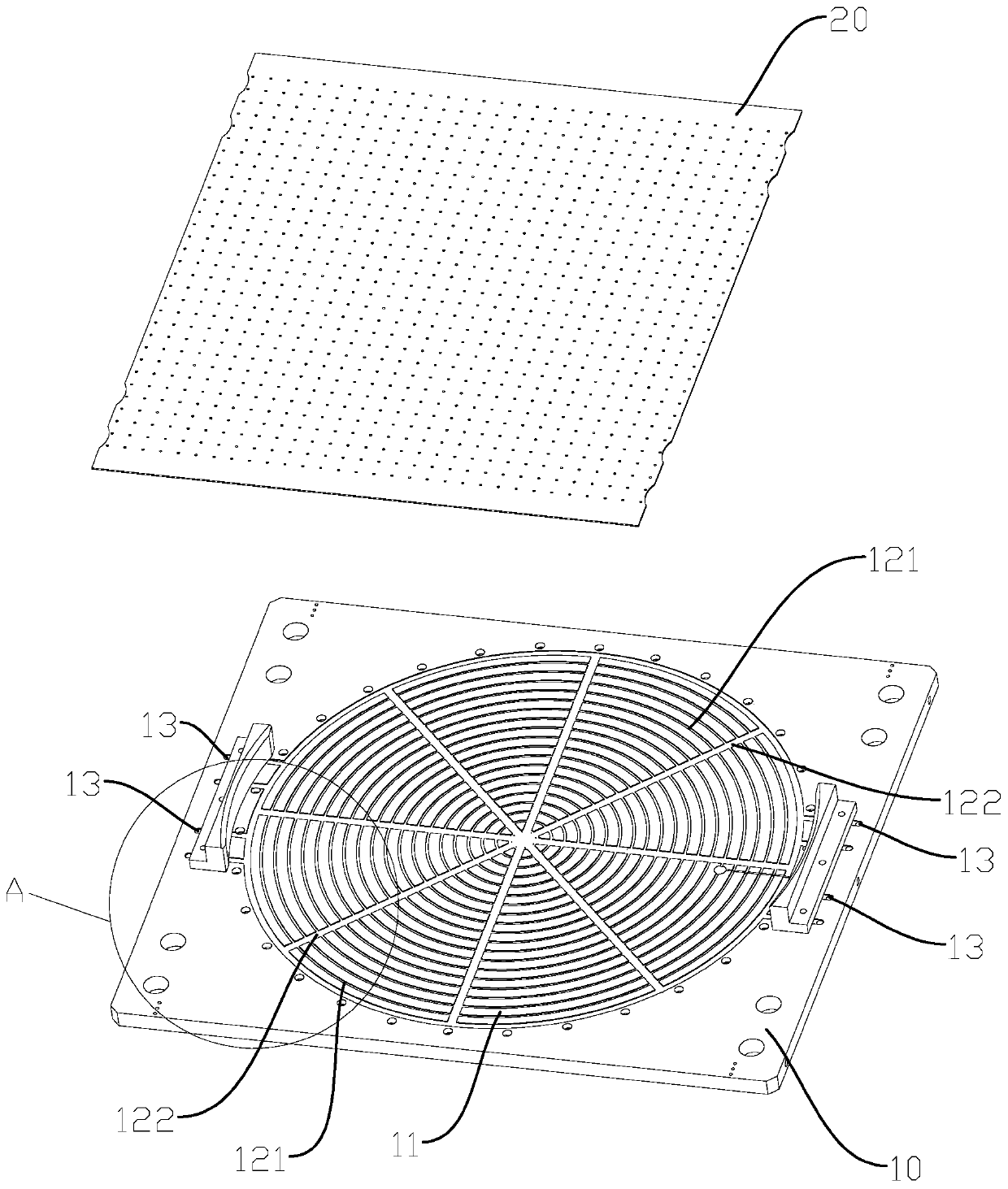

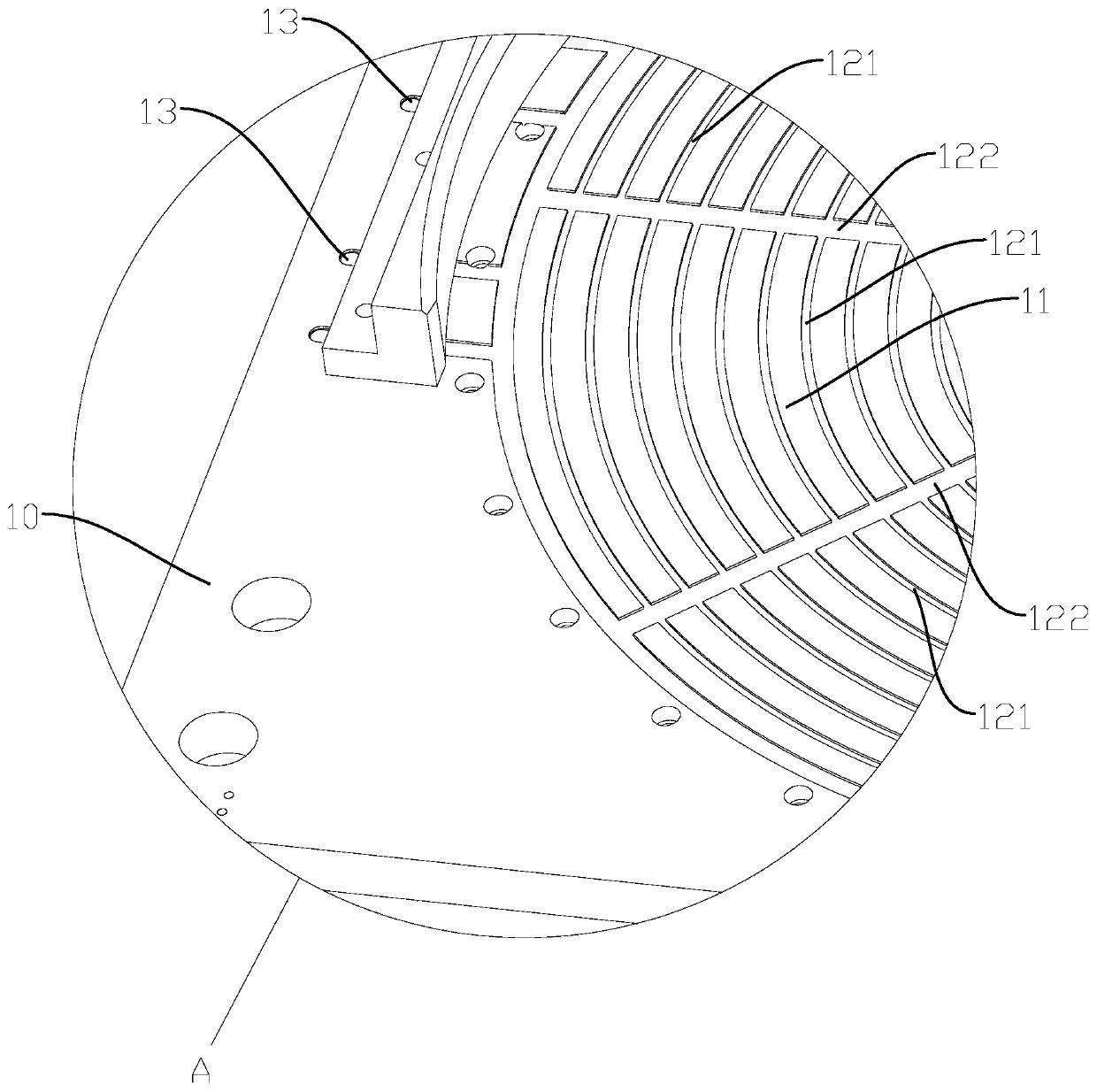

[0017] refer to Figure 1 to Figure 3 , a preferred embodiment of the present invention, a sludge dewatering extrusion die, comprising an extrusion die main body 10, an extrusion die main body 10 has an extrusion part 11, and the extrusion part 11 is provided with a diversion groove, and the diversion groove Spreading outward from the center of the extrusion part 11, the extrusion die main body 10 is provided with a drain 13 communicating with the diversion groove. In the present invention, since the outwardly diffused diversion grooves are provided on the extruding part 11, the water generated during the sludge extrusion process can gather in the diversion grooves and be guided by the diversion grooves to flow outward and pass through Drainage through the outlet 13 is less prone to turbulent flow and silting, can effectively improve drainage efficiency, reduce the amount of water reabsorbed by sludge, can effectively improve the dehydration rate of sludge, and also helps to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com