Longitudinal and transverse coupled pressure application-based fatigue test device

A fatigue test, cross-arm technology, applied in the direction of measuring devices, using applied stable tension/compression to test the strength of materials, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

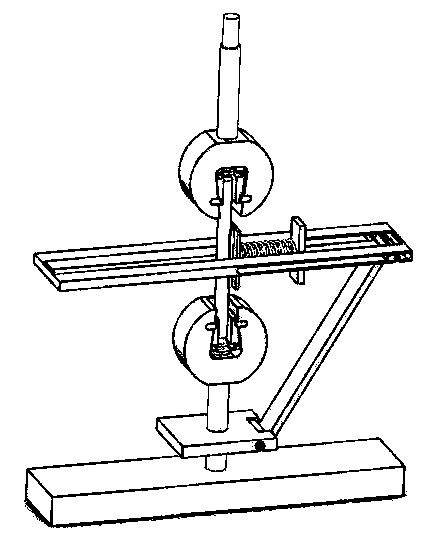

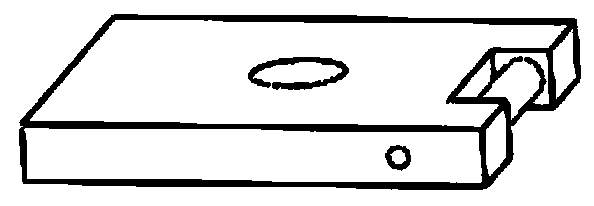

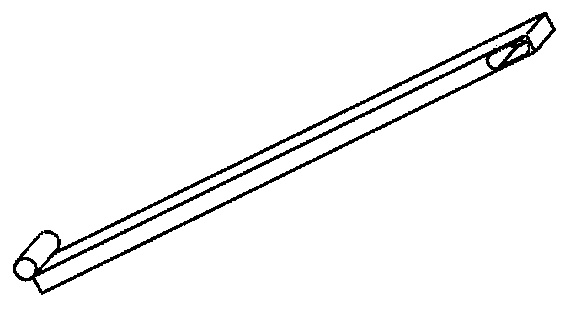

[0019] like figure 1 Shown is a two-way force fatigue test device, including a base, an oblique arm, a slide bar, a cross arm, and a fixture. The base and the lower end of the oblique arm are connected by an iron column and fixed with two screws, and the oblique arm can freely rotate left and right around the iron column. The upper end of the oblique arm is also interspersed with an iron column. The oblique arm can freely rotate left and right around the column. The iron column is placed in the horizontal chute at the right end of the cross arm. Clamp the test piece firmly. Under the force of the oblique arm, the iron column can slide left and right along the chute, compressing or stretching the spring on the left side of the slide bar, thereby exerting lateral pressure or tension on the specimen. This structure can be applied to a general standard fatigue testing machine, so as to apply tension or compression in the longitudinal direction and simultaneously apply compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com