Special amorphous transformer core calibration installation rack

A technology of transformer iron core and mounting frame, applied in the direction of transformer/inductor magnetic core, transformer/inductor parts, electrical components, etc. Transformers cannot reach the service life and other problems, and achieve the effects of small energy loss, low overall use cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

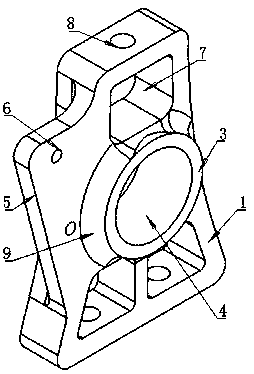

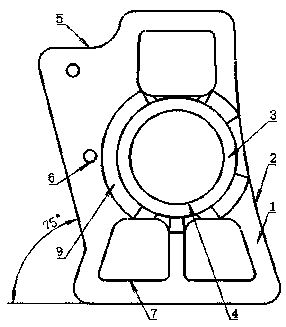

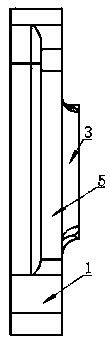

[0020] Such as Figure 1 to Figure 7 As shown, a special amorphous transformer iron core calibration installation frame, which is used in conjunction with the calibration connection seat, can provide more accurate position accuracy for the iron core assembly in the amorphous transformer, so that the amorphous transformer can be used in the later stage The overall safety in the use process is better, the energy loss in the use process is smaller, and the overall use cost of the amorphous transformer is lower. The calibration mounting bracket can be operated manually or through mechanical cooperation. The operation mode is more flexible and convenient to use, and it cooperates with each other through the structure of the center position and the right position during the calibration operation, which can ensure better stability during calibration. It includes a main body stabilizing support connecting plate 1, and the right side of the main body stabilizing supporting connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com