Connection device for hydraulic circuit

A technology for connecting devices and hydraulic circuits, applied in clutches, couplings, mechanical equipment, etc., to solve problems such as increasing the maximum pressure that can be supported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

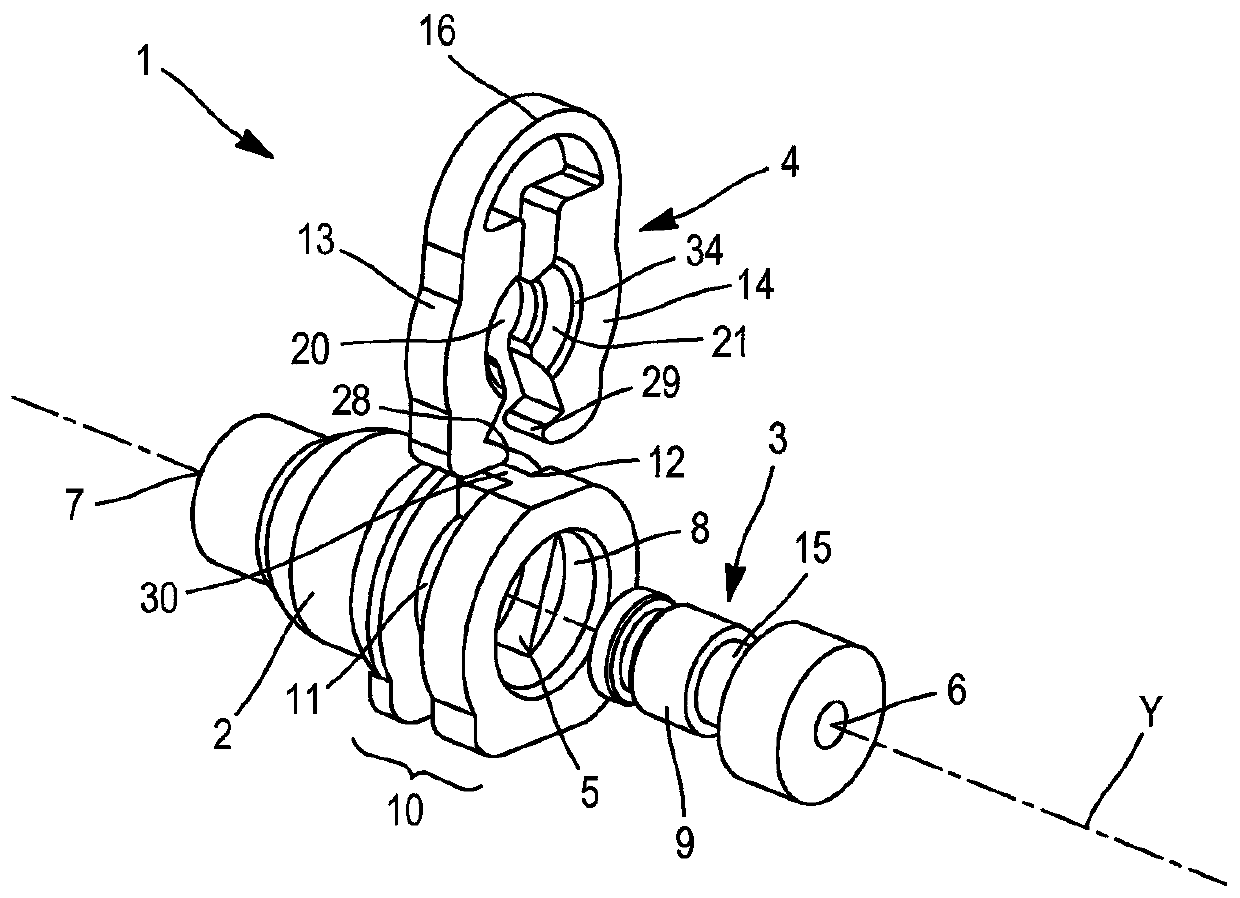

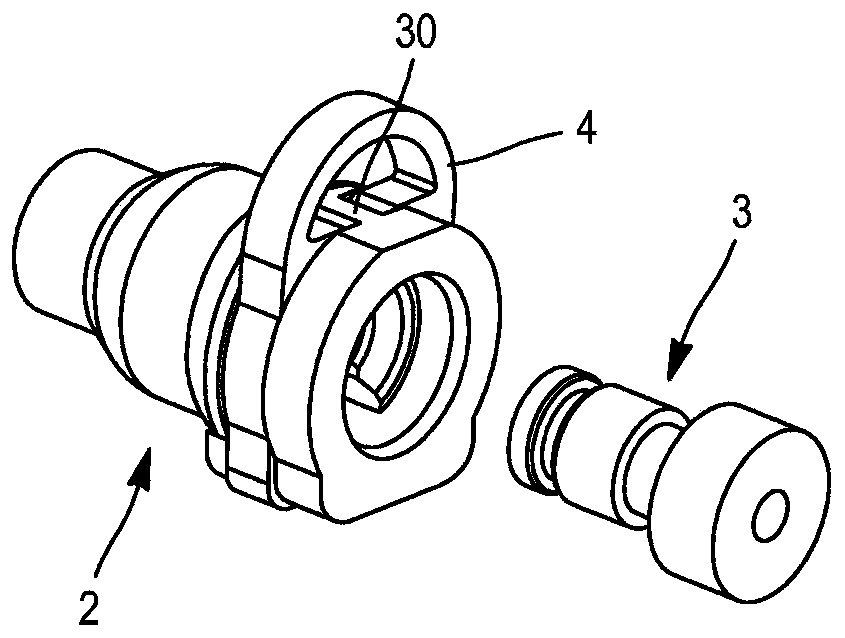

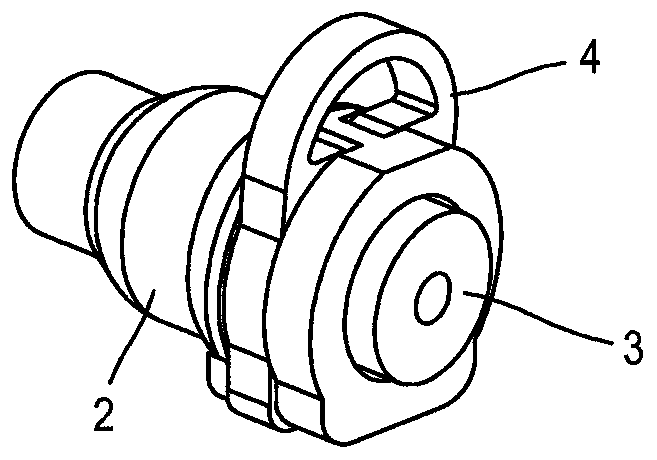

[0041] Figure 1 to Figure 3 Shown is a hydraulic circuit connection device intended to be integrated into a hydraulic system for controlling a motor vehicle clutch to connect two hydraulic conduits together.

[0042] Such as Figure 1 to Figure 3 As shown in , the connection device 1 has three main components: a female connector 2 , a male connector 3 and a locking clip 4 . The male connector 3 can be accommodated in the female connector 2 in the axial direction. The locking clip 4 is intended to keep the male connector 3 engaged in the female connector 2 .

[0043]The locking clip 4 has two arms 13 and 14 connected together by an elastic connecting portion 16 to form a substantially U-shape. The locking clip 4 is made of a single piece of plastic, such as polyamide 6-6, advantageously reinforced with glass fibres. When a force is exerted on the arms 13 and 14, the two arms 13 and 14 of the locking clip 4 can be elastically separated from each other to reach the separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com