Water-absorbing paper cocooning frame and manufacturing method thereof

A manufacturing method and grid cluster technology, which can be applied to other household appliances, household components, household appliances, etc., can solve the problems of many yellow spots on the upper cocoon, medium cocoon quality, and non-absorbent, so as to improve the quality of silkworm cocoons and reduce the manufacturing cost , The effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

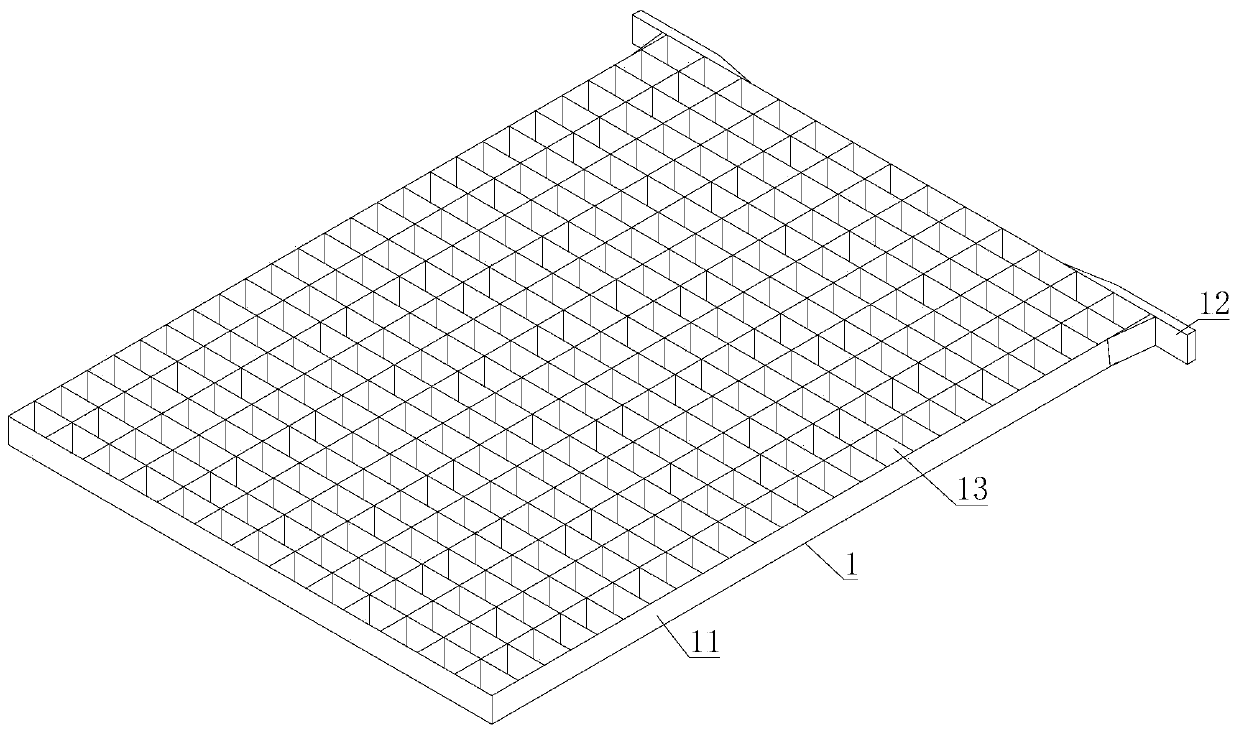

[0044] Such as figure 1 As shown, a water-absorbing grid cluster includes a grid cluster main body 1. The grid cluster main body 1 includes a square frame 11, a handle 12 is fixed on one side of the square frame 11, and several grid pieces 13 are connected in the square frame 1. Several grid sheets 13 are spliced into several grids, and water-absorbing sheets are pasted on the grid sheets.

[0045] The water-absorbing sheet is pasted on the grid cluster main body 1, then the water-absorbing sheet on the grid cluster main body 1 can absorb water, so as to avoid the situation that there are many macular cocoons and the quality of silkworm cocoons is not high when the grid cluster is too wet. The water-absorbing sheet is one of chemical fiber silk, down, cotton, sponge block and the like. When silkworms cocoon on the grid cluster of the present invention, the silk can be well adsorbed on the water-absorbing sheet on the grid cluster main body 1, and the silk is not in contact ...

Embodiment 2

[0047] A method for manufacturing a water-absorbing grid cluster, comprising the steps of:

[0048] a) Making the grid cluster main body 1 by injection molding;

[0049] a1) Use a detergent to clean the main body 1 of the grid cluster, rinse the main body 1 of the grid cluster with clean water, and dry it;

[0050] b) Spray glue on the surface of the grid cluster main body 1;

[0051] c) rubbing a part of the grid cluster main body 1 so that the grid cluster main body 1 is electrostatically charged, and spraying the water-absorbing sheet onto the surface of the grid cluster main body 1 to obtain a water-absorbing grid cluster;

[0052] d) Drying the square clusters covered with absorbent sheets.

[0053] The grid cluster main body 1 is made by injection molding, so the plastic grid cluster main body is not easily deformed, ensuring the stability of the grid cluster main body 1, and the plastic grid cluster main body 1 has a relatively low manufacturing cost and will not caus...

Embodiment 3

[0059] A method for manufacturing a water-absorbing grid cluster, comprising the steps of:

[0060] a) Making the grid cluster main body 1 by injection molding;

[0061] a1) Use a detergent to clean the main body 1 of the grid cluster, rinse the main body 1 of the grid cluster with clean water, and dry it;

[0062] b) Spray glue on the surface of the grid cluster main body 1;

[0063] c) The electrostatically charged object is contacted with the main body 1 of the grid cluster and then separated so that the main body 1 of the grid cluster is charged with static electricity, and the water-absorbing sheet is sprayed onto the surface of the main body 1 of the grid cluster to obtain a water-absorbing grid cluster;

[0064] d) Drying the square clusters covered with absorbent sheets.

[0065] The grid cluster main body 1 is made by injection molding, so the plastic grid cluster main body is not easily deformed, ensuring the stability of the grid cluster main body 1, and the plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com