A water conservancy engineering device for river channel dredging

A technology for water conservancy projects and river channels, which is applied in water/sewage treatment, solid waste removal, and multi-stage water/sewage treatment. It can solve problems such as low separation effect, damage to treatment equipment, and secondary environmental pollution. Increased cost, avoidance of intermediate links, and the effect of efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

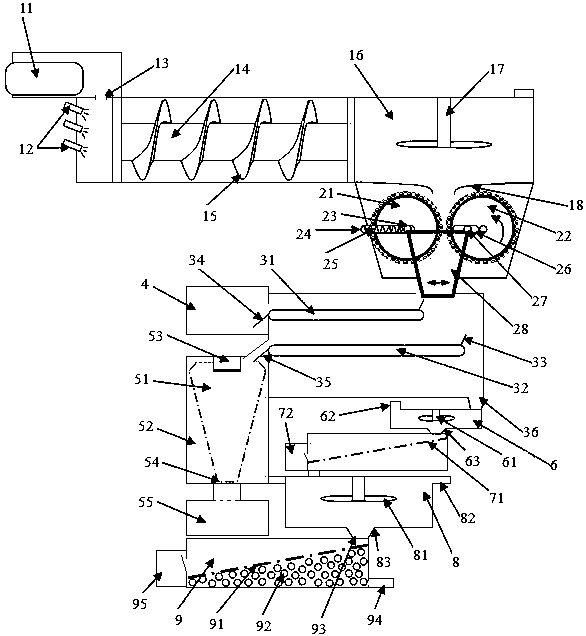

[0032] A water conservancy engineering device for river channel dredging includes a crushing chamber, a stone removing device, a transfer chamber, a centrifugal separation chamber, a first mixing chamber, a first filtering chamber, a second mixing chamber and a second filtering chamber.

[0033] The crushing chamber includes a crushing chamber casing, a dredge pump, a high-pressure nozzle, a crushing chamber inlet, a crushing shaft, a crushing knife, a mixing chamber, an upper stirring shaft, and a crushing chamber outlet; the dredge pump is arranged on the outer top of the crushing chamber casing, It is connected with the entrance of the crushing chamber arranged on the top of the shell of the crushing chamber. The dredger pump is used to suck the silt in the river into the crushing chamber through the entrance of the crushing chamber. There is a cavity directly below the entrance of the crushing chamber. Three high-pressure nozzles are arranged on the side wall of the cavity,...

Embodiment 2

[0047] A water conservancy engineering device for river channel dredging includes a crushing chamber, a stone removing device, a transfer chamber, a centrifugal separation chamber, a first mixing chamber, a first filtering chamber, a second mixing chamber and a second filtering chamber.

[0048] The crushing chamber includes a crushing chamber casing, a dredging pump, a high-pressure nozzle, a crushing chamber inlet, a crushing shaft, a crushing knife, a mixing chamber, an upper stirring shaft and an outlet of the crushing chamber; two crushing shafts are connected in series, and the suction The dredge pump is set on the outer top of the shell of the crushing chamber and communicates with the entrance of the crushing chamber set on the top of the shell of the crushing chamber. There is a cavity directly below the cavity entrance, and five high-pressure nozzles are set on the side wall of the cavity. The high-pressure nozzles break up the sludge by spraying water at high pressur...

Embodiment 3

[0062] A water conservancy engineering device for river channel dredging includes a crushing chamber, a stone removing device, a transfer chamber, a centrifugal separation chamber, a first mixing chamber, a first filtering chamber, a second mixing chamber and a second filtering chamber.

[0063] The crushing chamber includes a crushing chamber casing, a dredge pump, a high-pressure nozzle, a crushing chamber inlet, a crushing shaft, a crushing knife, a mixing chamber, an upper stirring shaft, and a crushing chamber outlet; the dredge pump is arranged on the outer top of the crushing chamber casing, It is connected with the entrance of the crushing chamber arranged on the top of the shell of the crushing chamber. The dredger pump is used to suck the silt in the river into the crushing chamber through the entrance of the crushing chamber. There is a cavity directly below the entrance of the crushing chamber. There are 6 high-pressure nozzles arranged on the side wall of the cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com