VOC waste gas comprehensive treatment system

A comprehensive treatment and exhaust gas technology, applied in the direction of gas treatment, combustion methods, dispersed particle filtration, etc., can solve the problems of lack of versatility, low efficiency of VOC exhaust gas treatment, high cost, etc., to solve the problem of desorption and ensure long-term work , Efficient adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

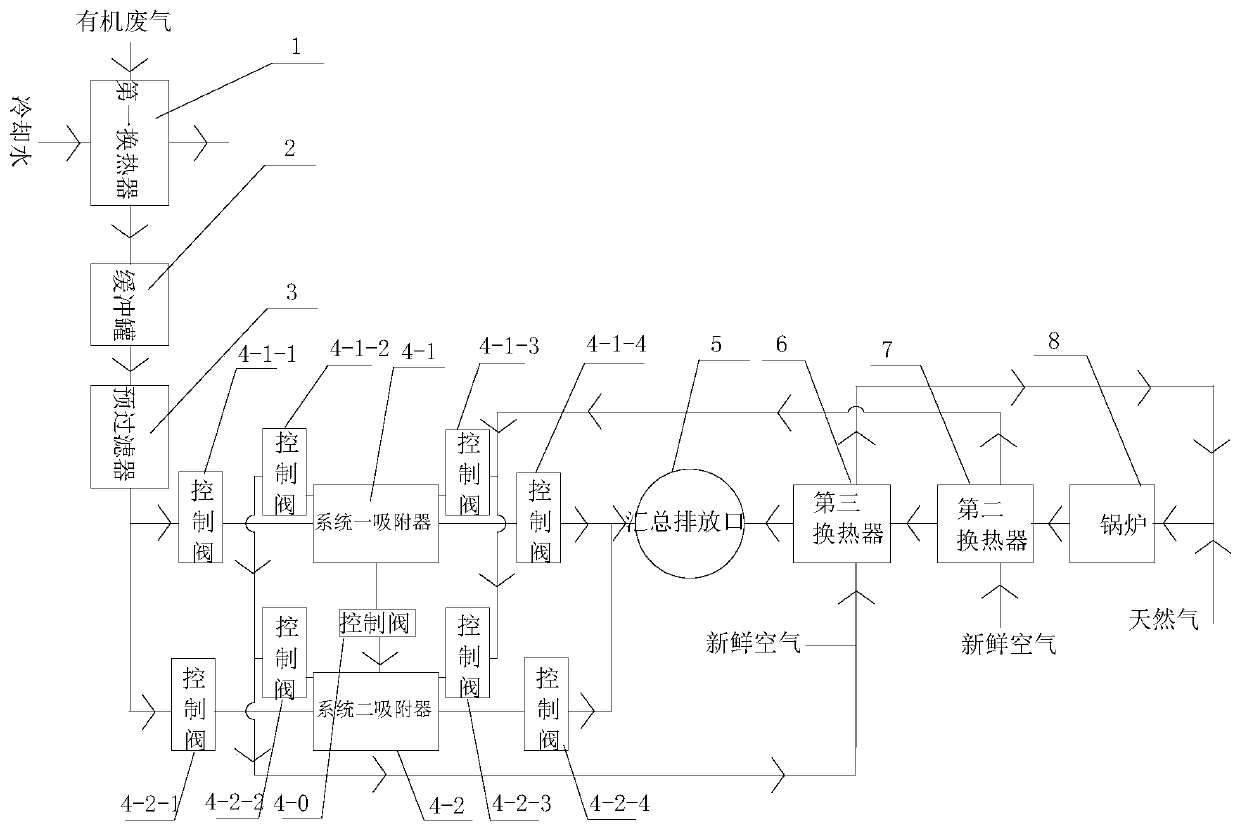

[0043] Below in conjunction with specific embodiment and appended Figure 1~6 , to further illustrate the present invention.

[0044] The present invention proposes a VOC waste gas comprehensive treatment system, as attached figure 1 As shown, including the adsorption unit and the natural gas boiler treatment unit, the natural gas boiler works intermittently:

[0045] When the natural gas boiler is not working, after the VOC exhaust gas passes through the first heat exchanger 1 to control the temperature, the temperature of the airflow is reduced to 30-40°C, the airflow passes through the buffer tank 2 at a steady flow rate, and then enters the pre-filter 3, and then the airflow enters the system 1 for adsorption Adsorber 4-1 and system two adsorber 4-2 are adsorbed, and the non-polluting gas after adsorption is discharged through the summary discharge port 5; in this embodiment, between the system one adsorber 4-1 and the system two adsorber 4-2 Set the series / parallel valv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap