Intra-assay circulation shaping spheroidizing system

An internal circulation and frustum-shaped technology, which is applied in chemical instruments and methods, chemical/physical processes, and methods for granulating raw materials, etc., can solve the problems of large number of equipment, low tap density, and low yield, and achieve improvement The effect of large range, small number of equipment and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

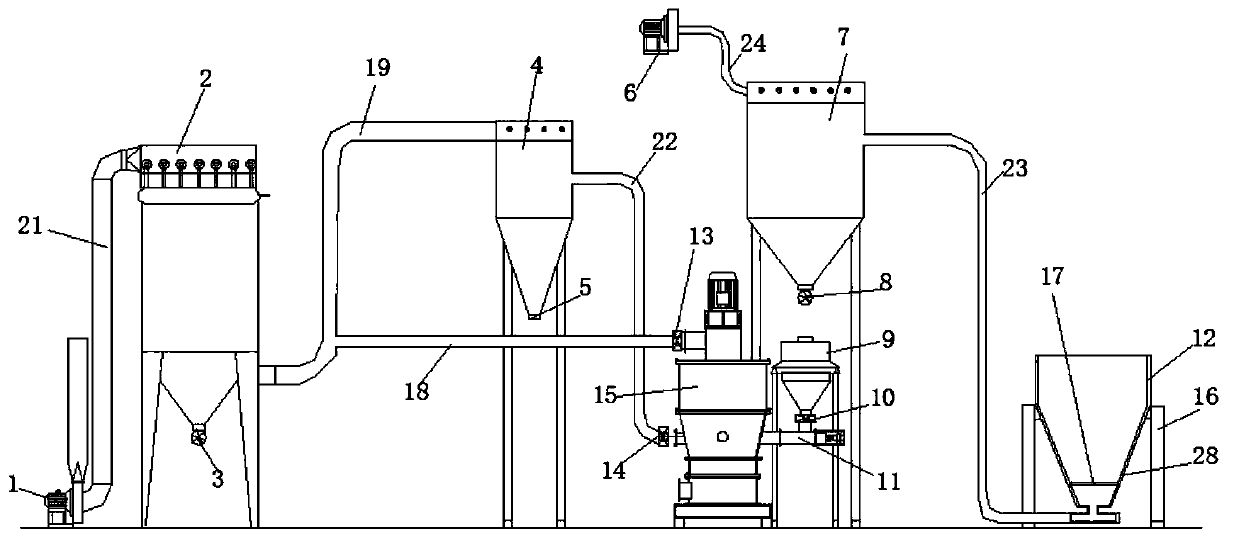

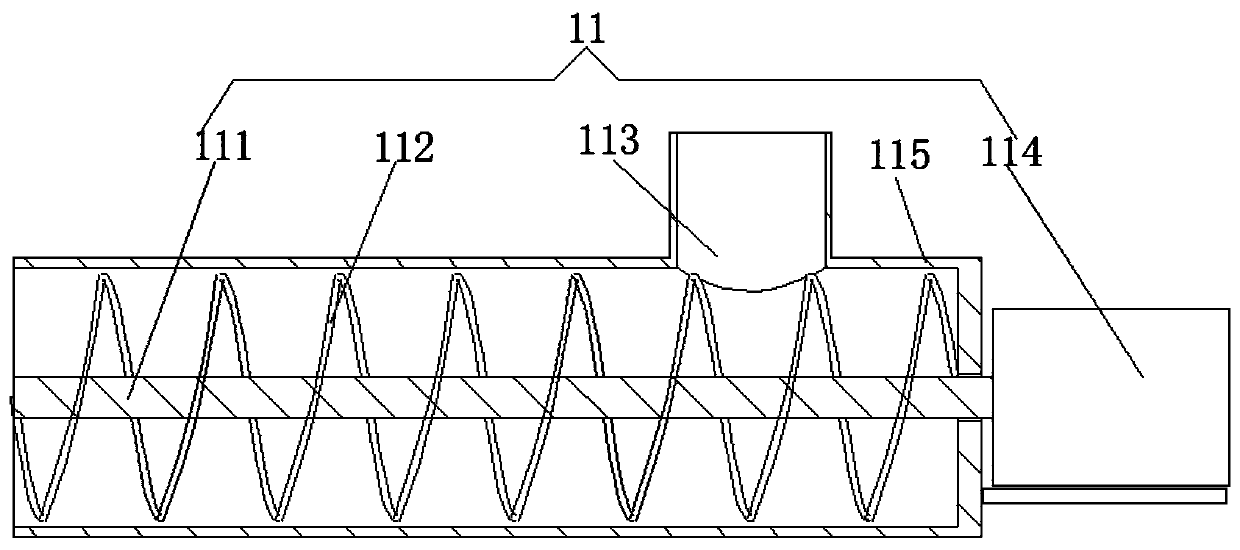

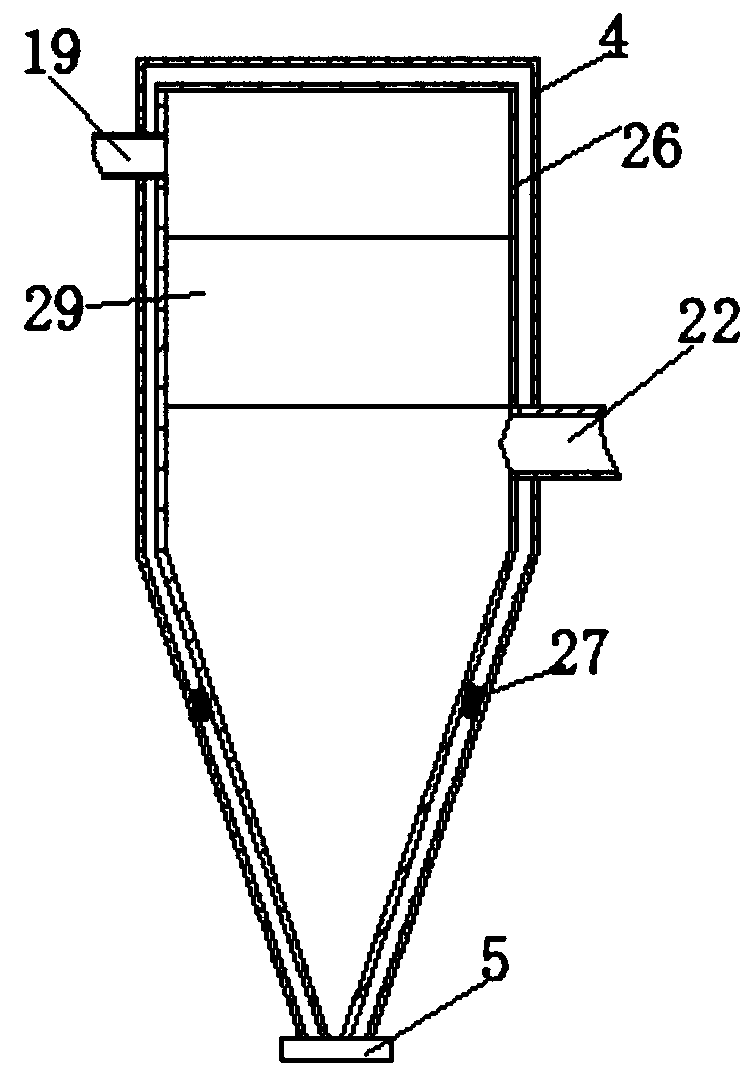

[0031] refer to Figure 1-5 , a batch internal circulation shaping spheroidization system, including an induced draft fan 1, the induced draft fan 1 is connected to an external power supply, a pulse dust collector 2 is placed on one side of the induced draft fan 1, and a pulse air shutoff device 3 is installed at the bottom of the pulse dust collector 2 One end of the induced draft fan 1 is connected with the first pipeline 21, the other end of the first pipeline 21 is connected with the pulse dust collector 2, the input end of the pulse dust collector 2 is connected with the second pipeline 19, and the other end of the second pipeline 19 is connected with the finishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com