Non-model robot multi-peg-in-hole assembly control method capable of using environment forecasting for optimization

A technology of predictive optimization and assembly control, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., and can solve a large number of problems such as attempts and unusable application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention proposes a non-model robot multi-axis hole assembly control method using environment prediction optimization, which is further described below in conjunction with the accompanying drawings and specific embodiments.

[0046] The present invention proposes a non-model robot multi-axis hole assembly control method using environment prediction optimization, including the following steps:

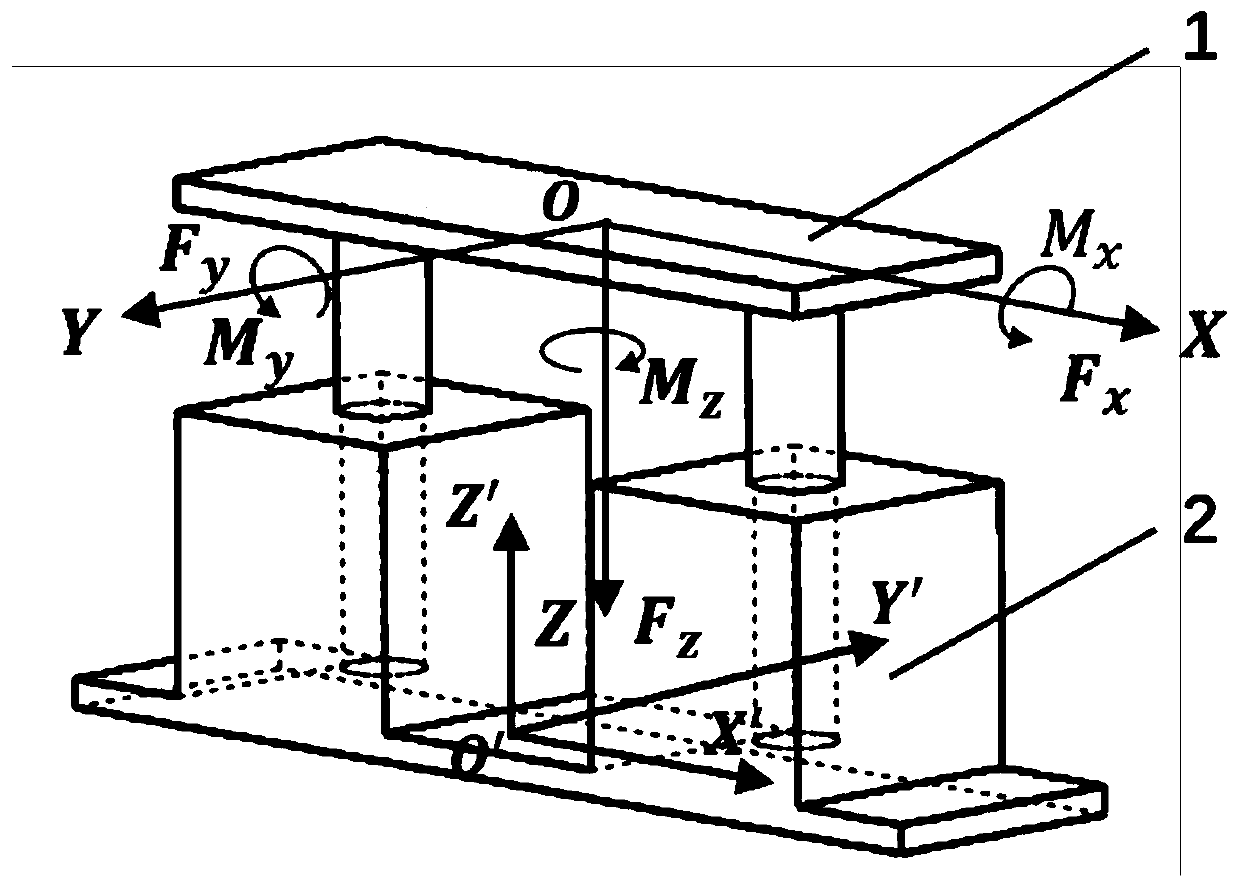

[0047] 1) Establish a biaxial hole assembly experiment platform, the structure of the biaxial hole assembly experiment platform is as follows: figure 1 as shown, figure 1 Among them, 1 is the dual-axis part to be assembled, and 2 is the dual-hole part to be assembled. Install any sensor that can collect six-dimensional force (the six-dimensional force sensor of ABB used in the present invention) to the end of the robot (the present invention can use a conventional model of robot, and this embodiment uses) ABB IRB 1200) for execution On the device, fix the double-ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com