Control system for multiple electrically driven hoisting beams by means of electric traction monorail crane

A control system, a technology of monorail hoisting, applied in the directions of cranes, load hoisting components, transportation and packaging, etc., can solve problems such as low efficiency of hydraulic hoisting systems, and achieve the effects of energy saving, easy control, and system cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

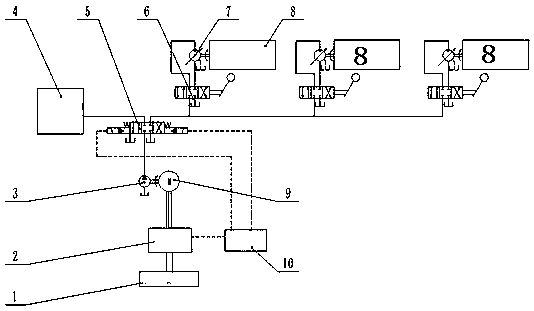

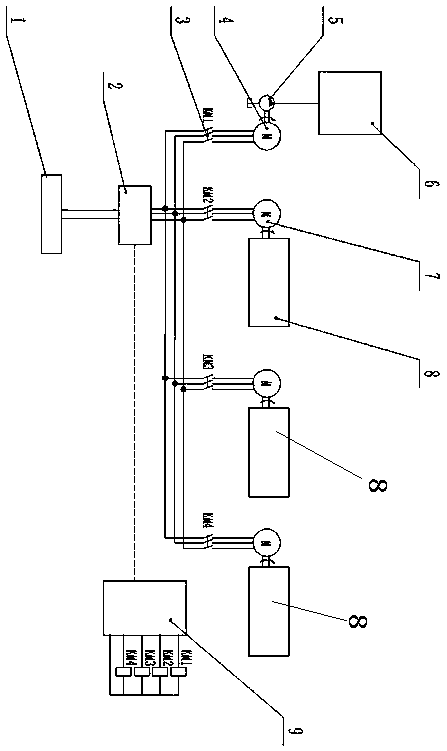

[0018] figure 2 As shown, the electric traction monorail crane multi-unit electric drive lifting beam control system, including monorail crane power battery 1, frequency converter 2, contactor 3, hydraulic pump station motor 4, hydraulic oil pump 5, monorail crane auxiliary hydraulic system 6, lifting motor 7. Lifting reducer 8. Control center 9.

[0019] The monorail crane power battery 1 supplies power to the frequency converter 2, and the output of the frequency converter 2 controls the motor 4 of the hydraulic pump station and multiple lifting motors 7 respectively. The motor 4 and the lifting motor 7 are connected in parallel. Inverter 2, which is connected to the control center. The motor 4 of the hydraulic pump station is connected with the hydraulic oil pump 5 to provide power for the auxiliary hydraulic system 6 of the monorail crane. The hoisting motor 7 is connected with the hoisting reducer 8 to provide power for the hoisting beam. The control center 9 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com