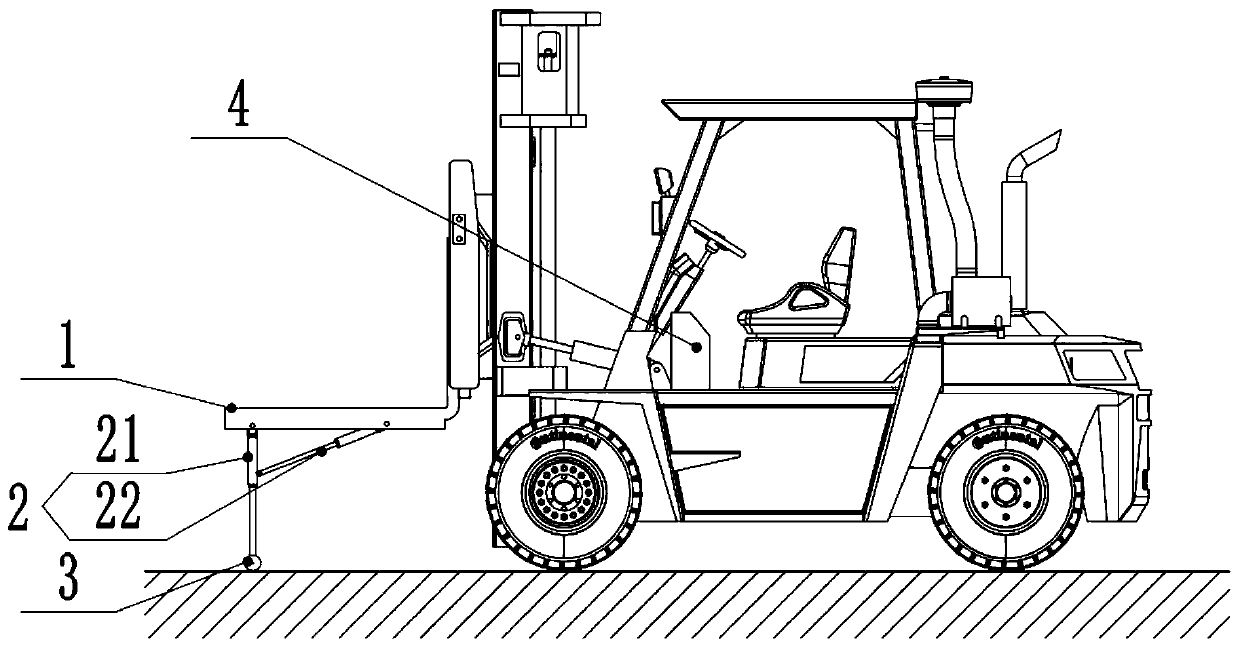

Forklift capable of preventing goods from inclining and inclination prevention method

A technology for forklifts and goods, applied in the direction of lifting devices, lifting equipment safety devices, fluid pressure actuation devices, etc., can solve the problems of forklifts being unable to move, rear wheels of forklifts tilted, forklifts tilted, etc., to reduce personnel and economy Loss, the effect of avoiding misuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

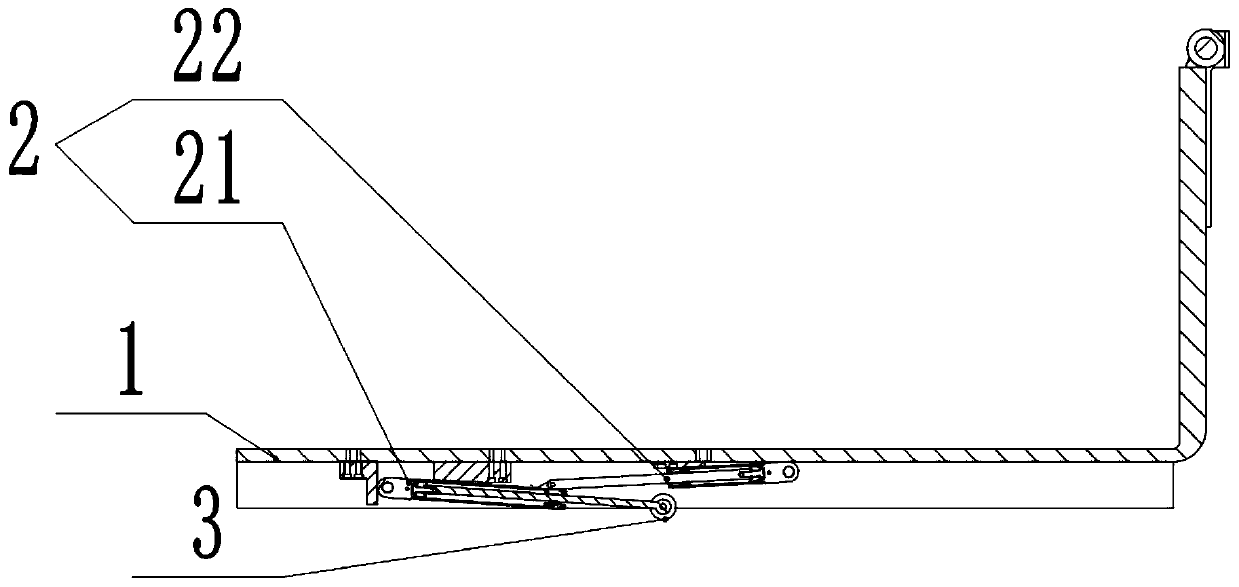

[0031] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

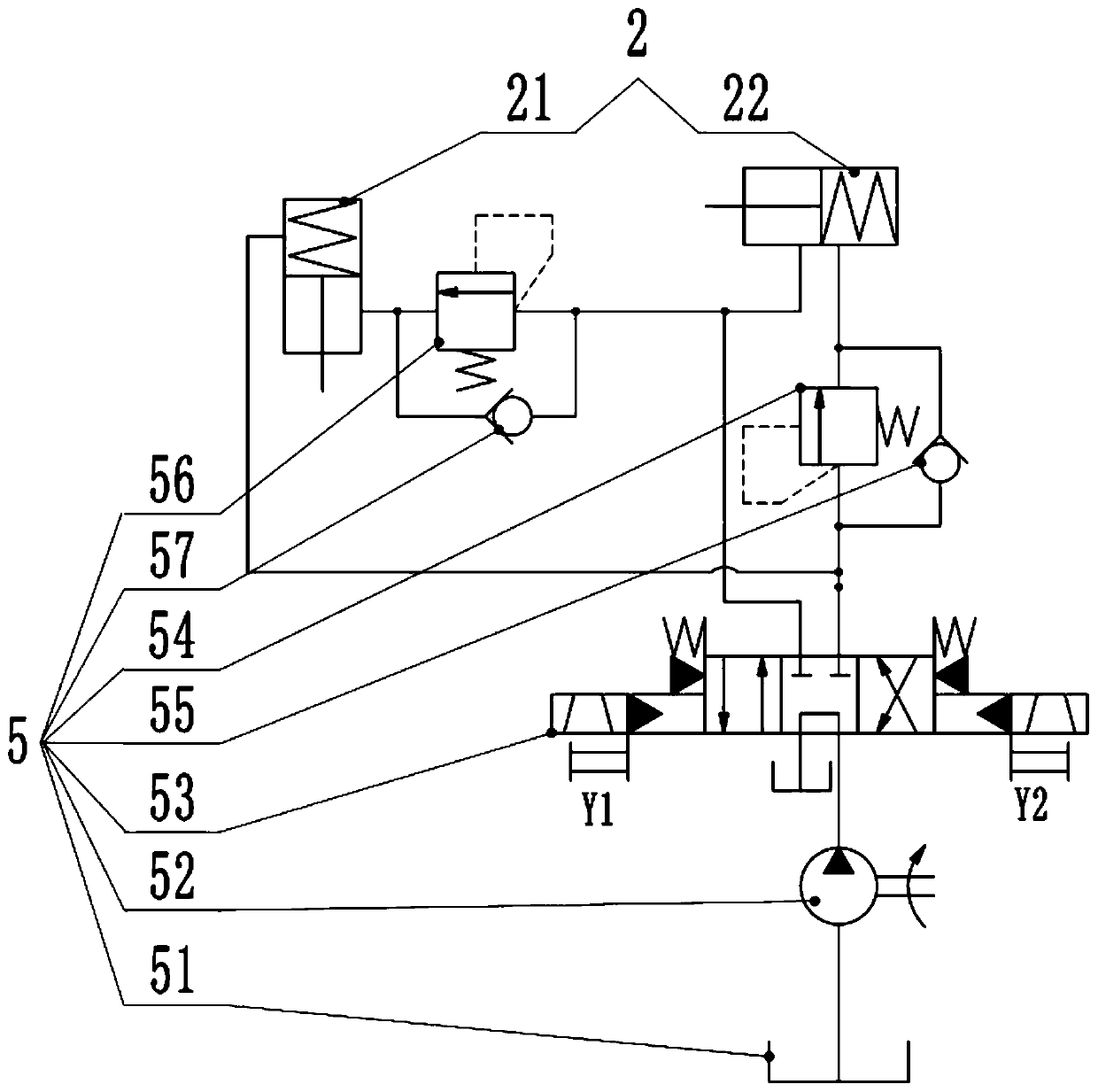

[0032] In this embodiment, the main oil tank 11 and the auxiliary oil tank 51 are welded by Q235 carbon steel plates. After the welding is completed, it is necessary to fill oil to check whether it is sealed. Hydraulic oil, wherein the volume of the main oil tank 11 is greater than the volume of the auxiliary oil tank 51 .

[0033]The models of the first hydraulic cylinder 21 and the second hydraulic cylinder 22 are HSGK hydraulic cylinders with hinged parts at the ends of the cylinder body and the telescopic rod, and the first cylinder body of the first hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com