Target grading model creation method for determining particle diameter based on continuous uniform probability

A technology of target gradation and particle size, applied in particle and sedimentation analysis, particle size analysis, instruments, etc., can solve the problems of high implementation difficulty and inconsistent with the continuity law of the actual transient filling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

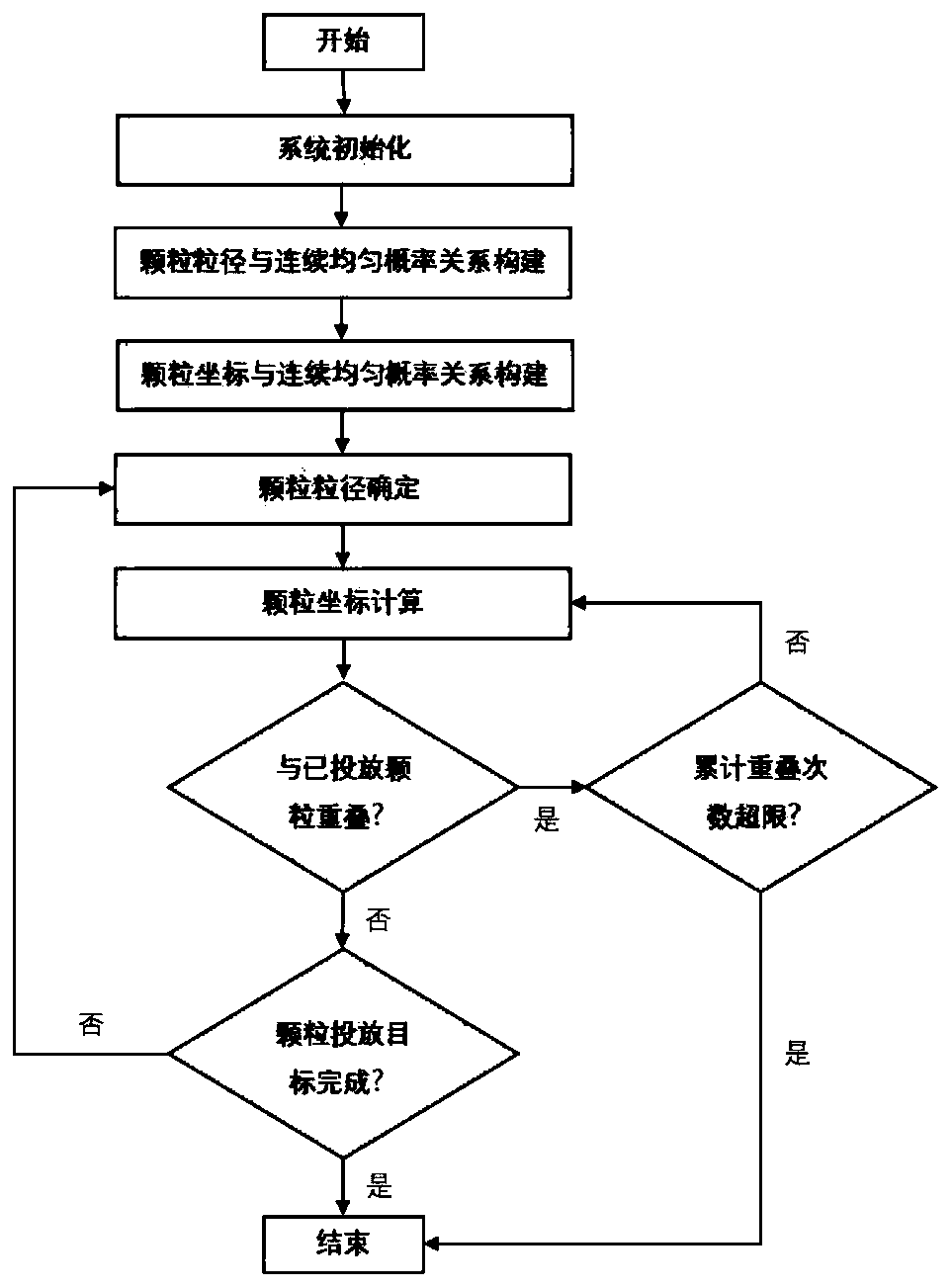

[0064] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0065] The present invention designs a method for creating a target gradation model based on continuous uniform probability to determine the particle size, which is used to realize the delivery of particles to the target space. In practical applications, the target space can be divided into two-dimensional areas and three-dimensional areas. There are two types of regions, and then the methods are executed separately for these two types of target spaces.

[0066] One is the two-dimensional area target space, such as figure 1 and Figure 2a As shown, the specific steps are as follows.

[0067] Step A. Obtain the particle grading curve corresponding to the particle type, and as Figure 3a As shown, according to the area size percentage of cumulative particles in the particle grading curve The relationship with the chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com