A battery polar plate lead paste formula and a preparation method for the battery polar plate

A battery and plate technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of uneven surface of the plate, uneven composition of lead paste, loss of function, etc., so as to delay softening and shedding, improve physical Bonding strength, the effect of preventing the lead paste from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

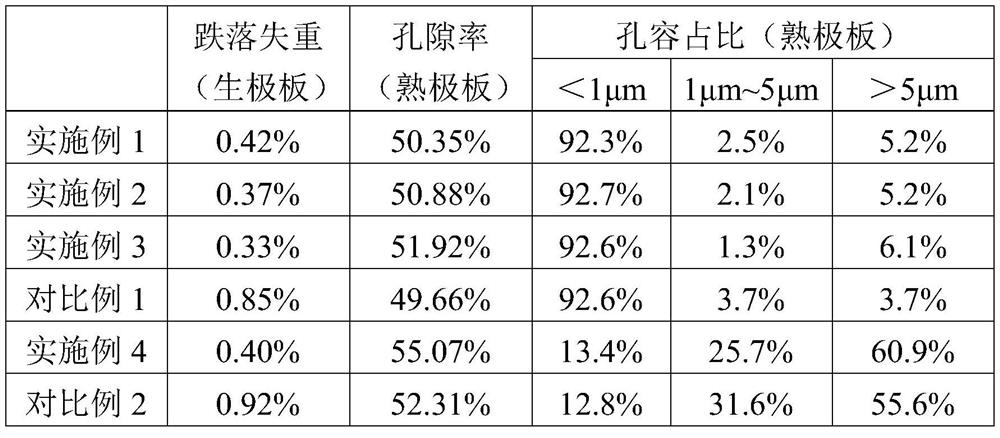

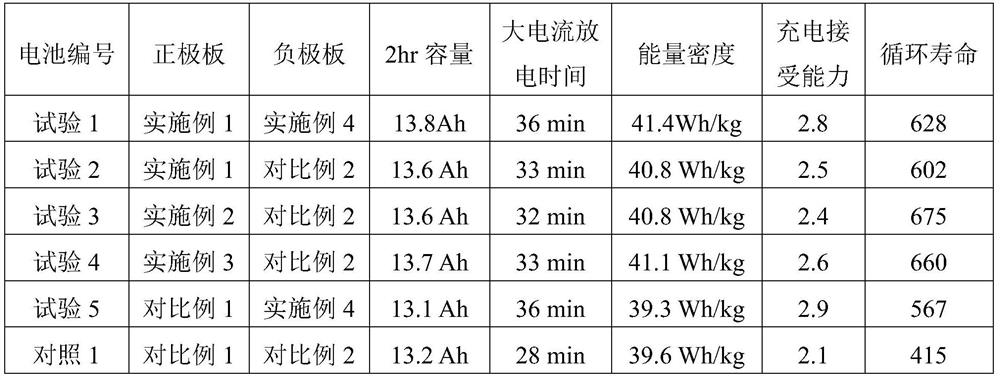

Embodiment 1

[0030] Positive plate: add red lead of 5% lead powder weight, 0.1% antimony trioxide and 0.2% graphite when making paste; add water-soluble PVA fiber (fineness is 0.3dtex, length 4mm, water The dissolution temperature is 65°C).

[0031] When mixing the paste, put the lead powder and the above formula into the paste mixing machine at the same time, turn on the paste mixing machine and dry mix for 3 minutes; then quickly add pure water with 12% of the weight of the lead powder, and then wet mix for 5 minutes; slowly add the lead powder by weight Dilute sulfuric acid with a concentration of 8% by weight and 50% concentration, add acid at a constant speed while stirring, control the acid addition time for 13 minutes, and turn on the air cooling and water cooling of the paste mixing machine at the same time when the temperature of the lead paste reaches 50°C to ensure the paste process The highest temperature is 60°C±2°C; after the addition of acid, continue to stir for 12 minutes ...

Embodiment 2

[0038] Positive plate: add red lead of 5% lead powder weight, 0.1% antimony trioxide and 0.2% graphite when mixing paste; add water-soluble PVA fiber (fineness is 1.0dtex, length 2mm, water The dissolution temperature is 75°C).

[0039] When mixing the paste, put the lead powder and the above formula into the paste mixing machine at the same time, turn on the paste mixing machine and dry mix for 3 minutes; then quickly add pure water with 12% of the weight of the lead powder, and then wet mix for 5 minutes; slowly add the lead powder by weight Dilute sulfuric acid with a concentration of 8% by weight and 50% concentration, add acid at a constant speed while stirring, control the acid addition time for 13 minutes, and turn on the air cooling and water cooling of the paste mixing machine at the same time when the temperature of the lead paste reaches 60°C to ensure the paste process The highest temperature is 68°C±2°C; after the addition of acid, continue to stir for 12 minutes ...

Embodiment 3

[0046] Positive plate: add red lead of 5% lead powder weight, 0.1% antimony trioxide and 0.2% graphite when paste; add water-soluble PVA fiber (fineness is 2.0dtex, length 6mm, water The dissolution temperature is 95°C).

[0047] When mixing the paste, put the lead powder and the above formula into the paste mixing machine at the same time, turn on the paste mixing machine and dry mix for 3 minutes; then quickly add pure water with 12% of the weight of the lead powder, and then wet mix for 5 minutes; slowly add the lead powder by weight Dilute sulfuric acid with a concentration of 8% by weight and 50% concentration, add acid at a constant speed while stirring, control the acid addition time for 13 minutes, and turn on the air cooling and water cooling of the paste mixing machine at the same time when the temperature of the lead paste reaches 60°C to ensure the paste process The highest temperature is 68°C±2°C; after the addition of acid, continue to stir for 12 minutes and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com