A kind of composite circuit board and preparation method thereof

A composite circuit and circuit board technology, used in printed circuit manufacturing, printed circuits, printed circuits, etc., can solve problems such as safety hazards, pins that are easy to scratch fingers, and components that are easily damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

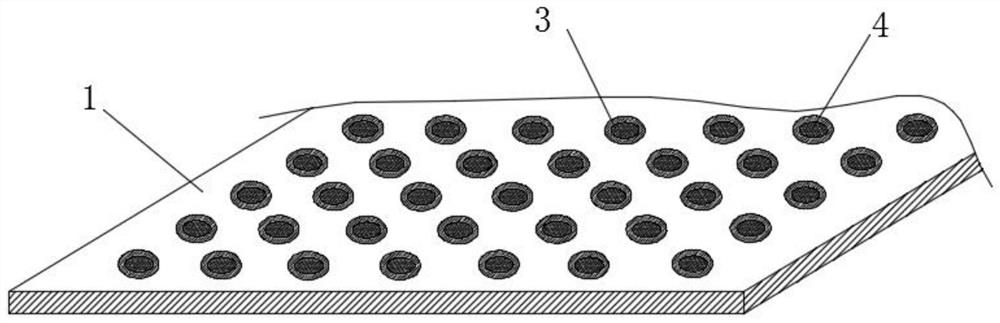

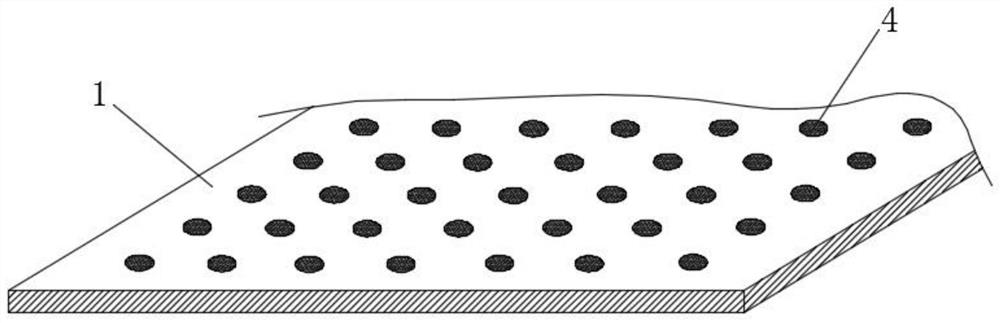

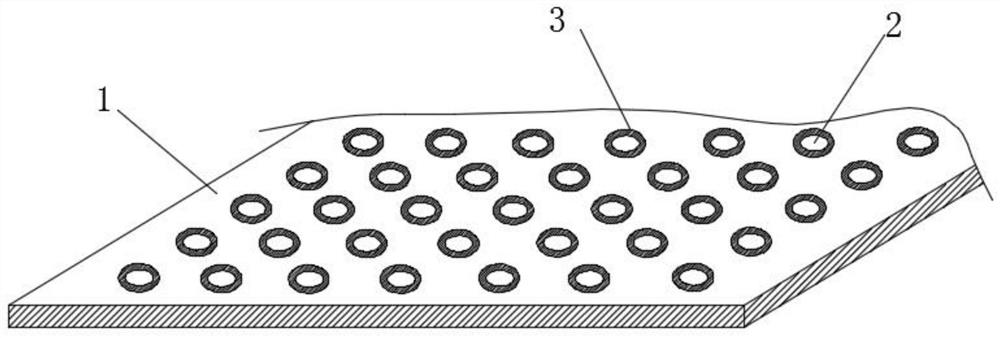

[0047] see image 3 , a composite circuit board, comprising a circuit board body 1, a plurality of jacks 2 are uniformly arranged on the circuit board body 1, a plurality of copper sheets 3 are connected to one end surface of the circuit board body 1, and the plurality of copper sheets 3 are connected to a plurality of Jack 2 matches, see figure 1 , the inner wall of jack 2 is connected with anti-reverse layer 4, please refer to Figure 5 and Figure 6 , the anti-reverse layer 4 includes a first anti-reverse layer 7 and a second anti-reverse layer 6, and the first anti-reverse layer 7 is located on the side of the socket 2 close to the copper sheet 3, and the second anti-reverse layer 6 is located on the side away from the socket 2 On one side of the copper sheet 3, set the socket 2 of the circuit board as a non-return type, so that the molten tin is not easy to seep out from the gap of the socket 2 and damage the components. When inserting components, only the pins of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com